Analysis of the importance of double flying fork parallel winding machine equipment: automatic winding machine due to its high efficiency, precision, low labor intensity, etc. has become the mainstay of the current winding production equipment, it is much higher requirements for functional components and accessory systems than the CNC winding equipment, each accessory plays a different function and role, different component configurations applied to different winding requirements, we mainly explain the tension mechanism Classification and characteristics.

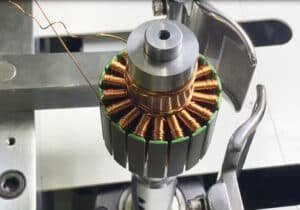

Automatic winding machine tension mechanism is a type of low-end models are commonly used, from felt, asbestos and other high friction system of the material as a friction piece, with a rotary friction piece, by adjusting the friction between the pressure torque to produce damping force, the advantages of low cost delivery, simple structure, easy maintenance and other features, of course, the disadvantages are also obvious, the tension adjustment is rough, poor self-control, inductive winding machine Generally applied to the tension requirements of the lower processing occasions. In order to achieve its high-speed, stable and very accurate coil winding, the design of automatic winding machine is commonly used in the control of microcontrollers, the use of stepper motors and frequency-controlled servo motors to achieve dual-motor rotary winding, and the application of infrared and Hall device detection for accurate measurement and control.

To ensure the quality of winding and to avoid wire breakage, the winding spindle is required to start and stop at a speed from slow to fast, and then smoothly transition from fast to slow. About CNC winding machine First of all, let’s understand what is CNC winding machine, refers to the technology of using digital instructions composed of numbers, words and symbols to achieve one or more mechanical equipment action control. What it controls are usually mechanical quantities such as position, angle, speed and switching quantities related to the flow of mechanical energy. The creation of CNC winding machines depends on the emergence of data carriers and data operations in binary form. The emergence of CNC winding machine equipment has greatly enhanced the civilization of modern industry. CNC is the abbreviation for digital signal control equipment, CNC winding machine with multiple coils and multi-functional models will replace single-head models, multiple coils and winding models can process more coils at the same time, reducing the cost of processing individual coils, the inevitable direction of future development of the coil production industry, while multi-purpose One-piece automatic winding machine is also a large number of production units to purchase wire splitting machine models, its processing range is very wide, round wire, flat wire can be wound, the extension of the processing capacity.

WhatsApp/Wechat : +86 13075286997

Email : sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]