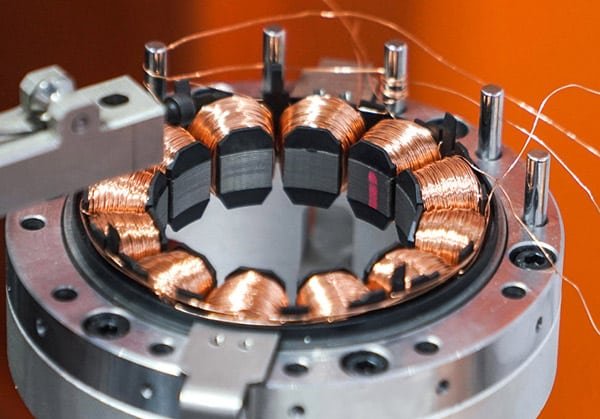

Brushless motor stator winding gradually using automation mode, generally using specialized winding machine equipment, different winding machine equipment configuration requirements also make a difference, the replacement of work is not the same, then what are the requirements for the setup of brushless stator automatic winding machine? How to quickly replace the fixture?Vacuz give you an introduction to it!

Brushless stator automatic winding machine setup requirements:

First, the winding machine setup requirements

1. Molds and configuration: molds need to be high-precision, winding machine should be equipped with professional servo control system and high-quality spare parts to improve the accuracy and speed of winding.

2.Stator parameters:

a. Wire: adjust the winding parameters according to the material and wire diameter to ensure the winding stability.

b. Wire diameter: although the fine wire is fast, but need to prevent stability problems, reasonable settings.

c. Stator size: outer diameter, inner diameter, stack thickness and slot distance all affect the winding speed and span, need to be set accurately.

d. Shape: Consider the effect of stator shape on winding efficiency.

e. Parameter setting: Based on the stator parameters and winding requirements, accurately set the winding speed, tension, number of turns and so on.

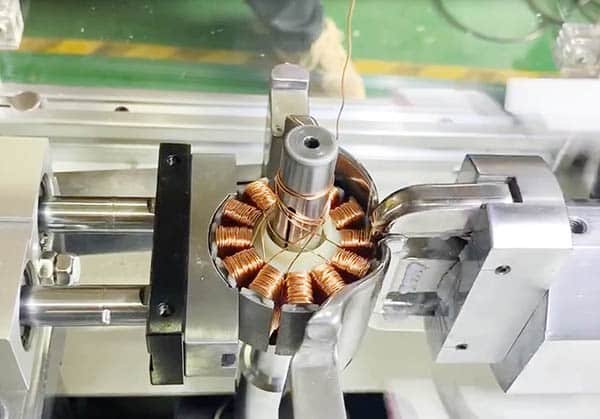

Second, the rapid replacement of the fixture method

1. Preparation: stop the machine, disconnect the power, confirm the fixture type is complete, check the status of the winding machine.

2. Disassemble the old fixture: shorten the wire and remove it carefully to avoid damage.

3. Clean the winding machine: Make sure the winding machine is clean and free of foreign matter before installing the new fixture.

4. Install the new fixture: hold it gently, fix the wire, adjust the alignment.

5. Test and adjust: start the test, adjust the parameters and position as needed to ensure that the winding effect meets the requirements.

Precautions:

1. Matchability: The fixture model needs to be strictly matched with the winding machine.

2. Gentle operation: Avoid damaging the winder or fixture during disassembly and installation.

3. Regular maintenance: Keep the winding machine in good condition to ensure long-term stable operation.

By following the above setup requirements and fixture replacement methods, the productivity and product quality of the brushless stator automatic winding machine can be effectively improved to meet the demands of modern industrial production.

Email : sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]