When discussing how the four-station fully automatic flying fork winding machine ensures winding consistency and stability, we have to go deep into its mechanical structure, control system, process parameters, environmental control and data monitoring and other dimensions. The following is a further expansion and optimization of the relevant content by Vacuz, aiming to present you with a richer and more in-depth analysis, hoping to help everyone!

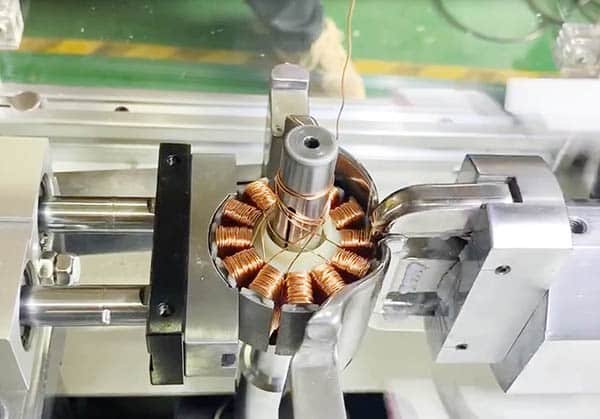

Brushless Motor Winding

1. Precision coordination of mechanical structure and transmission system

The mechanical structure of the four-station fully automatic flying fork winding machine is the basis for ensuring its efficient operation. By adopting high-precision transmission components such as precision ball screws, linear guides and couplings, the equipment realizes the accurate positioning of the flying fork and the stator slot, effectively avoiding the wire arrangement deviation caused by mechanical clearance, thereby ensuring the accuracy of winding.

The collaborative design of the die head and the guard plate is also a highlight of the equipment. The elastic die tongue equipped with the die head can adapt to the stator slot size, and the advancement error is also controlled within ±0.02mm to ensure that the enameled wire can be accurately inserted into the slot. The surface of the guard plate is mirror-polished, and the friction coefficient is reduced to below 0.1, which greatly reduces the resistance of the enameled wire during movement and effectively avoids the problem of wire damage or wire breakage.

2. Intelligent collaboration of control system and algorithm optimization

In terms of control system, the four-station fully automatic flying fork winding machine adopts advanced servo closed-loop control technology. Through the coordinated work of the bus-type PLC motion controller and the servo motor, the equipment realizes the dynamic matching of the flying fork speed and the die head feed speed, and the efficient response speed provides a strong guarantee for the stable operation of the equipment.

In addition, the equipment also adjusts the tension in real time through the PID algorithm, and the fluctuation range is strictly controlled within ±2%. The application of this technology effectively avoids the problem of loose winding or breakage caused by sudden changes in tension. In terms of multi-station synchronous control, the design of four-station independent servo drive enables the phase synchronization error of each station to be controlled within ±0.5°, thereby ensuring the consistency of the winding starting point of each station.

III. Fine control of process parameters and wire management

In terms of process parameters, the four-station fully automatic flying fork winding machine can dynamically adjust the tension according to the different wire diameters. For example, for a wire diameter of 0.1mm, the equipment will automatically set the corresponding tension to 2~3N. This fine control method effectively avoids the problem of overlapping wires due to insufficient tension or excessive tension causing wire damage. At the same time, the linkage adjustment of winding speed and tension is also a major feature of the equipment. When winding at high speed (≥2000r/min), the equipment will automatically reduce the tension by 10%~15% to ensure the integrity of the wire.

In terms of wire management, the equipment has carried out strict pretreatment and inspection of the enameled wire to reduce the friction resistance during the winding process. At the same time, the equipment is also equipped with a laser diameter gauge that can monitor the changes in wire diameter in real time. Once the error is found to exceed ±2%, the equipment will immediately trigger an alarm to ensure the quality of the wire.

IV. All-round consideration of environment and maintenance guarantee

In order to ensure the stable operation of the four-station fully automatic flying fork winding machine, the equipment has also made careful considerations in the environmental control of the installation site. The equipment requires the temperature of the installation site to be controlled between 20±2℃ and the humidity to be ≤60%. The setting of this environmental condition effectively avoids the problem of mechanical accuracy change caused by thermal expansion and contraction. At the same time, the equipment foundation adopts a shock-absorbing design, and the vibration amplitude is controlled within 0.01mm, thereby preventing the jitter that may occur during the winding process.

Regularly checking the wear of the ball screw (≤0.05mm/year) and the accuracy of the servo motor encoder (≤±0.01°) is an important measure to ensure the stable operation of the equipment. In addition, monthly full machine calibration is also an indispensable link. The calibration content includes the adjustment of parameters such as the flying fork rotation center, die head feed amount, and tension sensor zero drift to ensure the accuracy and stability of the equipment.

V. Intelligent management of data monitoring and feedback

In terms of data monitoring and feedback, the four-station fully automatic flying fork winding machine also shows its intelligent characteristics. Through the sensor to collect parameters such as tension, speed, position, etc., the sampling frequency of the equipment reaches ≥1kHz, so that the data curve of the winding process can be generated in real time.

Establishing a fault model based on the analysis of historical data by machine learning algorithms is also a major innovation of the equipment. The application of this technology enables the equipment to predict potential problems such as tensioner wear and servo motor overheating in advance, so as to take timely preventive measures.

The equipped HMI (human-machine interface) enables the winding status, fault code and solution of the equipment to be displayed to the user in real time. This function greatly shortens the downtime of the equipment and improves the operating efficiency of the equipment.

3 Sets Vacuz 1 Ton Automatic Servo Pressing Machine + 2 Sets Four Stations BLDC Motor Stator Coil Flying Fork Winding Machine Shipment

In summary, the four-station fully automatic flying fork winding machine has successfully achieved efficient guarantee of winding consistency and stability through the coordinated control and precision design of multiple dimensions such as mechanical structure, control system, process parameters, environmental control and data monitoring. This all-round and intelligent design concept not only improves the operating efficiency and quality level of the equipment, but also brings users a more convenient and efficient use experience.

Email: sales@vacuz.com