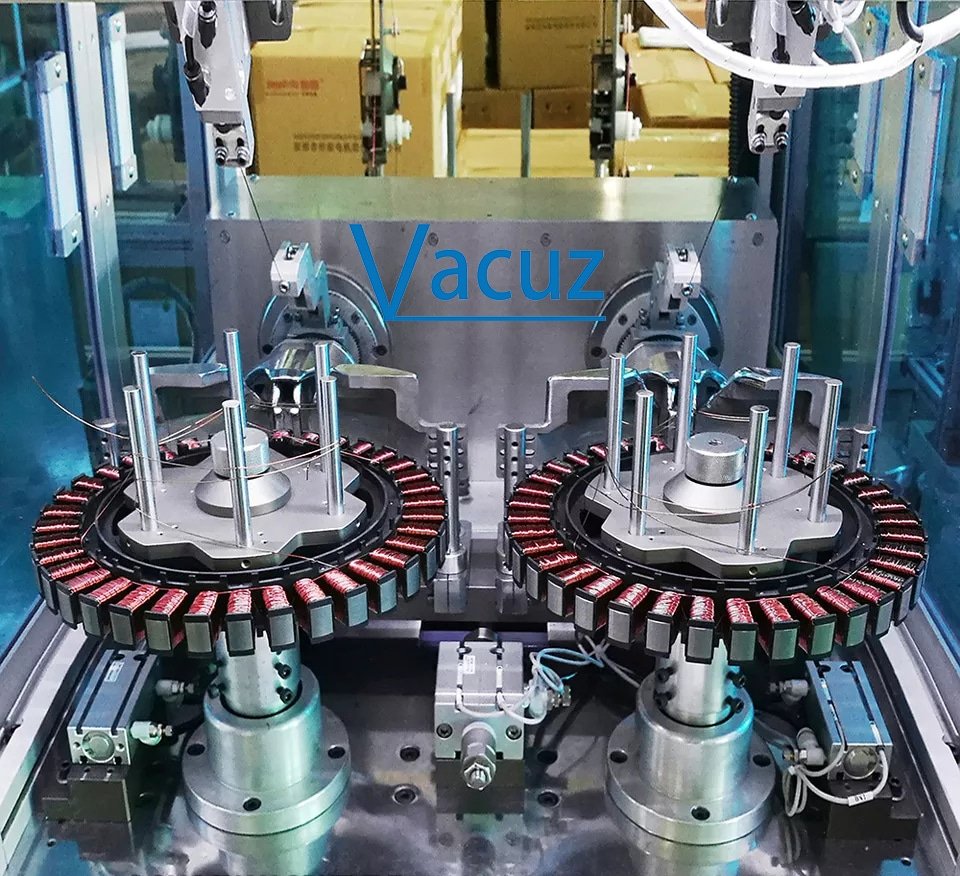

How can we improve the yield rate of brushless fully automatic stator winding machines? What are some good methods and tips? Improving yield rate requires coordinated optimization across multiple dimensions, including equipment, processes, and personnel. Below are detailed implementation plans and technical highlights for these six core areas. Vacuz will provide a brief analysis:

I. Improving Equipment Precision: The Foundation of Mechanical Stability

1. Mechanical Calibration

High-Precision Inspection: A laser rangefinder (0.001mm accuracy) is used to calibrate the mold mounting position, ensuring a first-turn positioning error of ≤0.01mm.

Leveling: A digital level (0.02mm/m graduation) calibrates the base, maintaining a level deviation of ≤0.05mm/m, minimizing vibration interference.

2. Dynamic Compensation Technology

The servo system’s feedforward compensation function automatically adjusts the wire pitch based on the rotational speed, with an accuracy of ±0.01mm, improving high-speed winding yield by 15%.

2. Tension Control Optimization: The Key to Wire Stability

1. Hardware Upgrade

High-precision tension sensor (error ≤ ±0.1% FS) + PID algorithm controls tension fluctuations within ±3%.

Low-Cost Alternative: Strain gauge sensors (accuracy ±2%) can reduce costs by 30%-50%.

2. Intelligent Parameter Adjustment

Preset tension based on the wire’s elastic modulus (e.g., 0.5-1.2N for 0.1mm copper wire) reduces wire breakage by 80%.

Establish a speed-tension mapping model, automatically compensating tension by 15% for every 1000rpm increase in speed.

3. Accurate Winding Parameter Setting: Phased Debugging

1. No-Load Test

Start with a speed between 30%-50% of the rated value and gradually adjust the speed (≤5% at a time), with an upper limit not exceeding 120% of the device’s calibration.

2. Variable-Level Verification

Increase the speed by 10%-20% at each level, run for 10 minutes or longer, and check the wire alignment.

IV. Mold and Stator Compatibility: Precision Determines Success

1. Mold Management

Regularly inspect mold wear. High-precision molds can reduce the wire overlap rate to ≤0.2%.

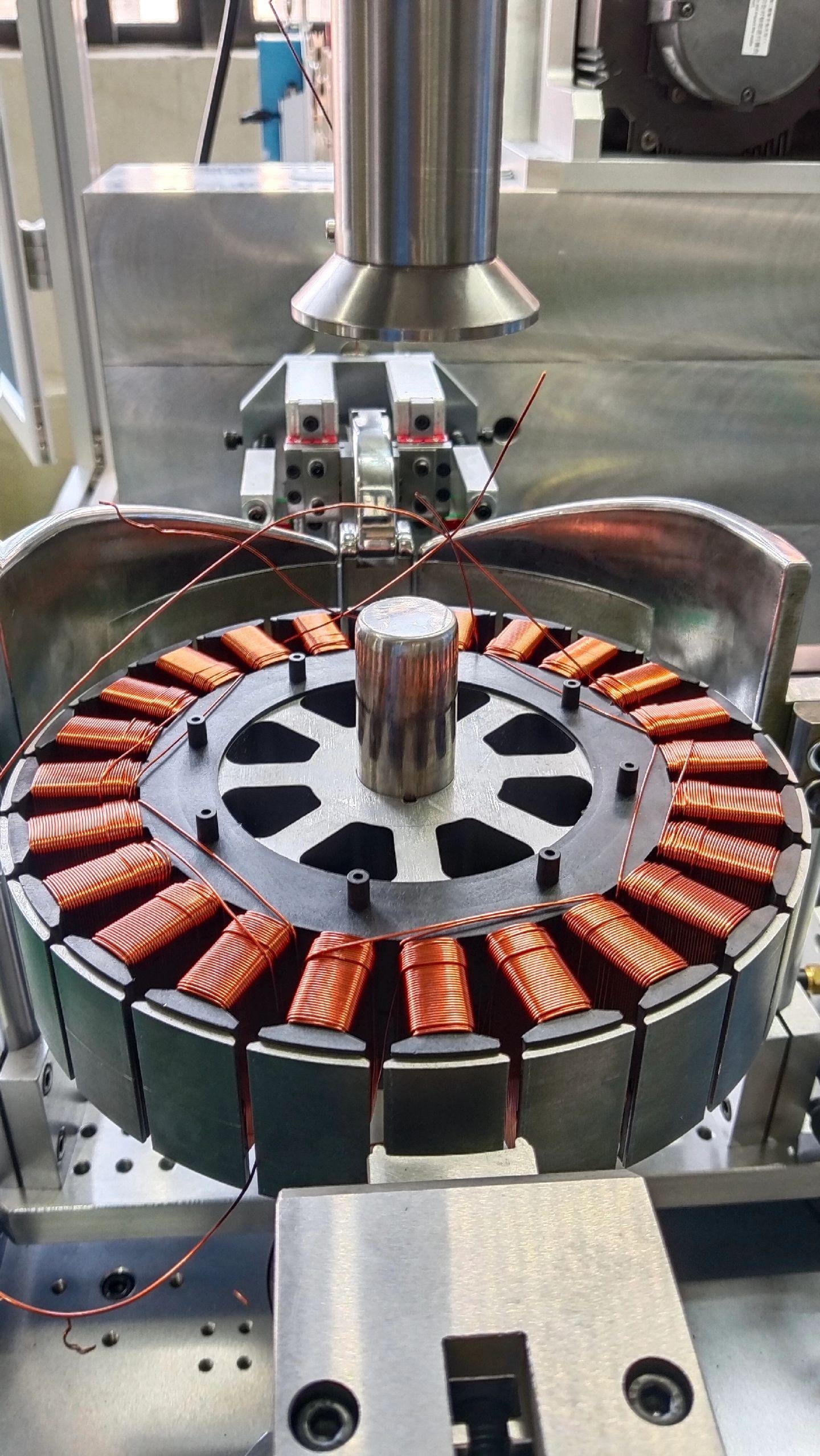

2. Stator Design Match

For outward-facing slots, use a flying fork winding machine; for inward-facing slots, use a needle-type internal winding machine. The mold should be polished and ground to avoid wire scratches.

V. Process Optimization: Full-Link Quality Control

1. Wiring Path Design

Optimize the wire distribution within the slot to avoid friction, reducing the wire damage rate from 1.5% to ≤0.2%.

2. Intelligent Detection System

Automatically tests resistance and insulation withstand voltage. Alarms are triggered when tension exceeds ±10%, reducing unexpected downtime by 70%.

6. Personnel Training and Management: Standardized Operations Reduce Costs and Increase Efficiency

Professional commissioning training, standardized operations, and phased training on no-load testing and machine calibration have reduced commissioning time for one company by 60% and maintenance costs by 40%.

How can we improve the yield rate of brushless fully automatic stator winding machines? What are some good methods and tips? Vacuz has provided a brief explanation above. We hope this information is helpful!