Familiar with automatic winding machine friends know that automatic winding machine is a very important winding machine equipment in coil mass production and processing, it has many advantages, such as automatic line, winding, counting, etc., not only efficient, but also very convenient, commonly used in transformers, motor coils and other production and processing enterprises, so how to wind automatic winding machine? How to ensure the accuracy of automatic winding machine winding coil number?

The winding process of the automatic winding machine is controlled by the CNC controller in order to control the start and stop of the spindle and the linkage operation of the winding system. the corresponding program is set according to the type of coils produced and processed in order to realize the winding process of the spindle, the left and right displacement settings of the winding and alignment mechanism, which makes the automatic stop when the number of windings reaches the set value. the function of the CNC controller has evolved from a single process to a modern multi-step sequential continuous operation. These functions are now available for common coil processing technologies and are favored by companies

Those who are involved in the micro-motor, electrical, transformer or instrumentation industries know that the number of turns of a coil has a significant impact on these products and does not allow for half-turn errors, so how do you ensure the accuracy of the coil count?

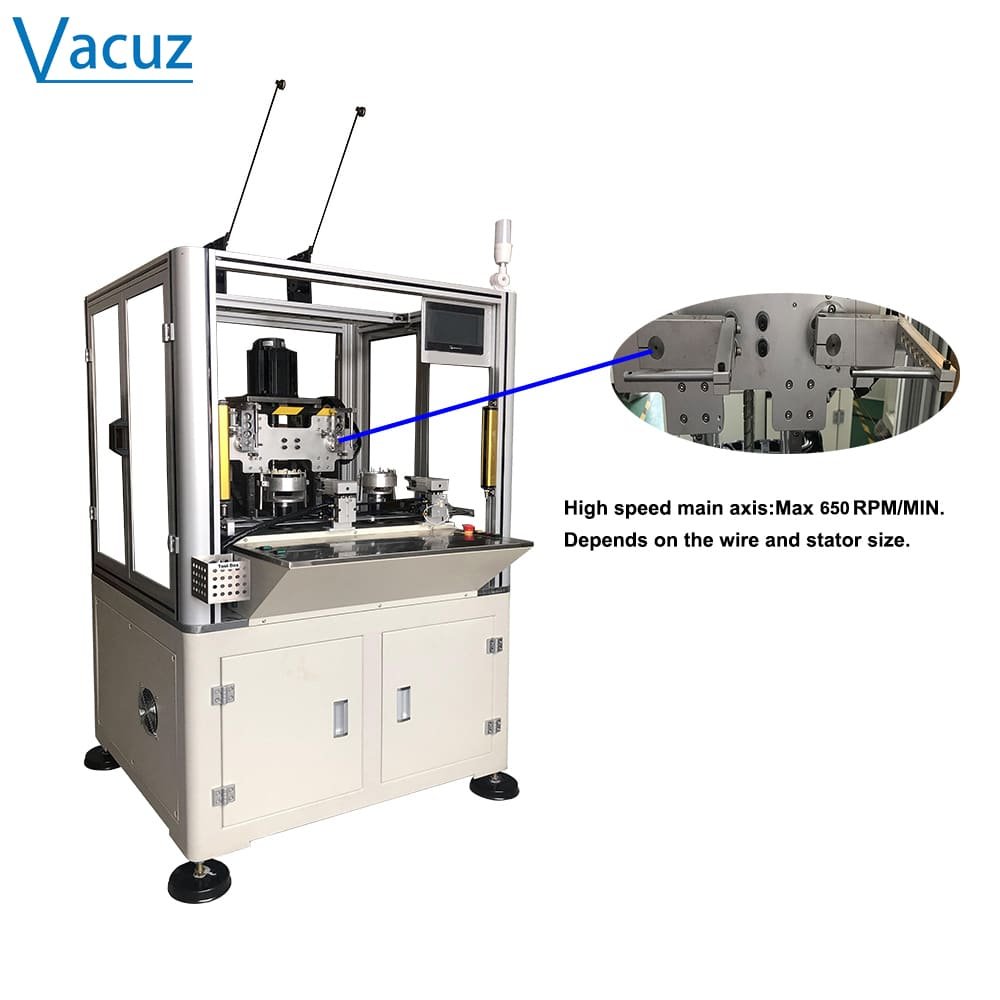

Automatic winding machines are mainly composed of spindle system, layout system, CNC system, mechanical structure, accessories, etc. The winding control ring of the winding machine consists of reed sensors, shaping circuits, counters, input settings and controllers. To control the accuracy of the coil turns, these aspects need to be noted.

The number of turns of the coil is reflected by the number of turns of the winding machine spindle. The reed sensor converts the number of turns of the coil into a pulse signal, which is shaped into a square wave by a shaping circuit and then differentiated to trigger the counter. When the input signal consisting of a single-pole two-position switch matches the counter’s counting signal, that is, if the number of turns to be wound is pre-specified and the number of turns wound matches, the circuit gate will open and send a signal to the controller to stop the motor winding to ensure accurate turn control.

From the above, it is easy to see that if you want to ensure the accuracy of the number of coils when running automatic winding machine, there must be strict requirements for technical personnel, after the unified training of enterprises, winding group winding qualified before running the winding machine

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]