With the rapid development of the motor industry, DC brushless motors are used more and more widely, and are now often used in home appliances, new energy vehicles, power tools, office equipment, industrial and commercial equipment, medical equipment, personal care, robotics and many other industries, and are favored by the majority of customers.

Many friends in the study of brushless motors, often ask a question, that is, how to wire DC brushless motor problems, has not been understood, Vacuz to introduce you! I hope you further understand the wiring method of brushless motor.

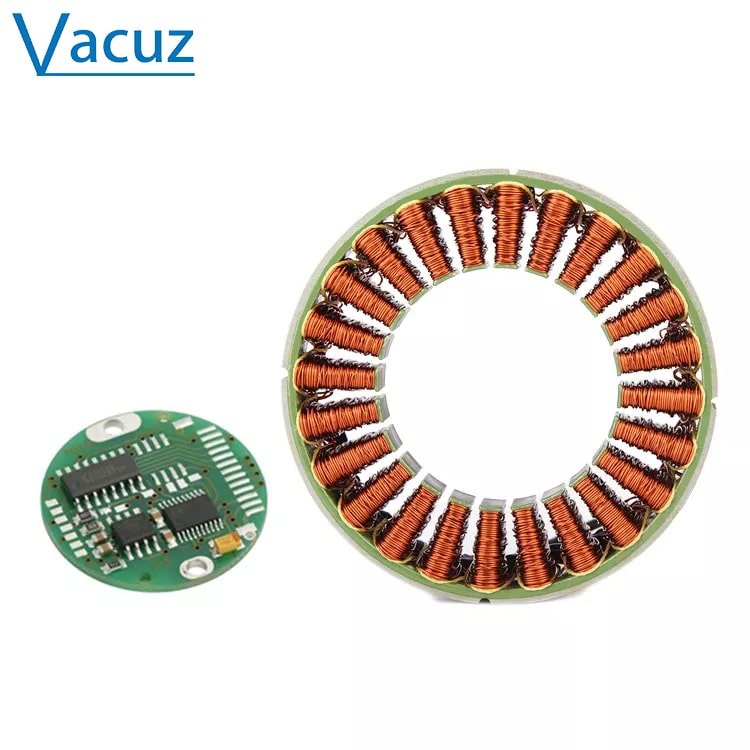

Brushless DC motor stator windings are mostly made into three symmetrical star connection, and three-phase asynchronous motor is somewhat similar to the magnetized permanent magnets connected to the rotor of the motor, in order to detect the polarity of the motor rotor, a position sensor is installed in the motor.

The driver consists of power electronics and integrated circuits, whose functions are: accepting motor start, stop and brake signals to control motor start, stop and brake; accepting position sensor signals and forward/reverse signals to control reverse rotation, changing the on/off of each power tube of the bridge to generate continuous torque; accepting speed command and speed feedback signals to control and adjust speed, providing protection and display, etc.

Brushless motor has 3 coil leads and 5 Hall leads, these 8 lines must correspond to the corresponding lines of the controller one by one, otherwise the motor cannot rotate properly.

Generally speaking, brushless motors with 60 degree and 120 degree phase angle need corresponding 60 degree and 120 degree phase angle brushless controllers to drive them. The controllers of the two phase angles cannot be directly interchanged, and the 8 wires connecting the 60 degree phase angle brushless motor to the 60 degree phase angle controller have two correct wiring, one for forward rotation and one for reverse rotation.

There are 36 ways to connect 3 thinner Hall phase wires, 3 thicker motor winding phase wires, to the controller, which can be energized when replacing the wires, but be careful and orderly, and the speed control handle should not be turned at too large an angle to avoid damaging the controller.

These are the common wiring methods of brushless DC motors, Vacuz hope that these basics can help you! Better understand the structure of brushless motors.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]