If a DC brushless motor is demagnetized, it is likely that an electromagnetic strike will occur, and if the situation is serious, the motor can only be replaced, so how can we tell that the motor is demagnetized? How about the causes and preventive measures? Take a look at it!

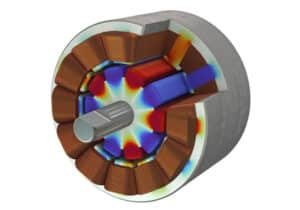

BLDC kefe nélküli egyenáramú motor

DC brushless motor demagnetization causes:

DC brushless motor performance is an important indicator of high temperature resistance level, if more than its temperature resistance level, its magnetic flux density will drop sharply, high temperature resistance level can be divided into: N series, resistant to more than 80 degrees; H series, resistant to 120 degrees; SH series, resistant to more than 150 degrees.

1, the motor cooling fan is abnormal, resulting in high motor temperature;

2, the motor is not set up temperature protection device;

3, the ambient temperature is too high;

4, the motor design is unreasonable;

How to prevent the DC brushless motor manufacturer demagnetization?

1, DC brushless motor power selection is correct

Demagnetization and motor power selection, the correct choice of DC brushless motor power can prevent or delay demagnetization, synchronous motor demagnetization is the main reason for high temperature, overload is the main reason for high temperature.

Therefore, in the selection of motor power to leave a certain margin, according to the actual situation of the load, generally in about 20% is more appropriate.

2、Avoid heavy load starting and frequent starting.

magnetic steel motor

Understanding the right way to prevent DC brushless motor demagnetization can save a lot of maintenance costs for the company, I hope these tips can help you!

WhatsApp/Wechat: +86 13075286997

E-mail: sales@vacuz.com