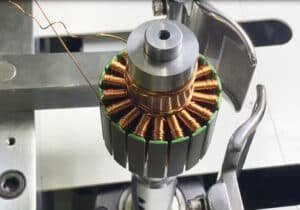

The most important process in the production and processing of the winding machine is the winding, and in addition to the automatic winding machine, the vast majority of factories use the production process is to separate the winding and inlay processing, which can ensure that many of the indicators basically meet the requirements. In addition to ensure that the process of winding will not harm the electromagnetic wire. External winding machine

Electromagnetic wire production and processing process, the winding method and the alignment of the results of the later use of a great impact, if the arrangement is scattered, or part of the electromagnetic wire stabbed into the spool, will lead to the coil winding process uneven delivery of electromagnetic wire, affecting the coil forming effect, serious damage to the electromagnetic wire will occur. In order to prevent similar problems, the respective winding process should be combined with a consensus with the electromagnetic wire supplier to control the weight of the single spool, the cooperation between the spool and the winding machine, and the arrangement of the electromagnetic wire to ensure that the production output meets the requirements of use.

Tekercs tekercselés

The three development stages of China’s electromagnetic wire industry, the start-up phase, the 1960s to mid-1980s, China established the production capacity of basic varieties of electromagnetic wire on the basis of self-reliance, with the infrastructure and expertise to develop new varieties, creating the necessary conditions for the development of the late 1980s to the 1990s. In the 1990s, enterprises in the wire industry gradually imported from advanced industrial countries a complete set of technology and equipment for the production of wire, from raw and auxiliary materials (wire cores, insulation materials, etc.), production equipment (wire drawing machines, enamelling machines and wrapping machines, etc.) to testing equipment for finished products, and the production capacity and technical level of wire gradually entered the world’s advanced ranks. Industrialization stage. Entering the 21st century, with the rapid development of the domestic electric power industry, home appliance industry, electronic information, communications industry, electromagnetic wire production enterprises in recent years to rapidly expand the scale of production. Old enterprises continue to eliminate out, new enterprises continue to produce, a new pattern of electromagnetic wire in China has basically formed, the industry has emerged a number of larger, strong technical strength of the enterprise, and gradually grow into the industry’s winding machine leader.

Now our country’s winding machine industry started very late, compared with developed countries there is a big gap. But our country’s winding machine market is large, and low labor costs. With the gradual adoption of advanced technology and equipment in the production of electromagnetic wire, and from which a breakthrough has been achieved. Wire winding machine and wire winding die have gradually closed the distance with the developed countries. External winding machine

WhatsApp/Wechat: +86 13075286997

E-mail: sales@vacuz.com