Rotor assembly involves numerous devices, both large and small. These devices ensure the rotor assembly process, accuracy, and efficiency. So, what are the accuracy and efficiency requirements for automated rotor assembly equipment? What are some common types of equipment? Vacuz will explain.

Vacuz Precision Agriculture Drone Motor Automatic FPV UAV External 2812 3115 3520 Stator Core Winding Machine Equipment

1. Precision Requirements: Full-Process Control from Micron to System Level

Precision is crucial in automated rotor assembly. From core component machining to overall system-level control, high-precision technology and equipment are required.

Core Component Machining Accuracy: Magnetic assembly requires high-precision positioning to ensure uniform magnetic field distribution. Air gap uniformity is also crucial, as it directly impacts the motor’s vibration and noise levels. Furthermore, dynamic balancing is crucial for ensuring rotor stability at high speeds.

System-Level Accuracy: High-precision sensors, vision systems, and encoders enable real-time monitoring of key parameters such as press force, winding tension, and displacement. Furthermore, a closed-loop feedback control system allows for real-time adjustment of assembly parameters to ensure stability and accuracy throughout the entire assembly process.

II. Efficiency Requirements: Comprehensive Optimization from Second-Level Cycles to Flexible Production

In modern production, efficiency is a key indicator of production equipment performance. Automatic rotor assembly equipment can significantly improve production efficiency by optimizing cycle time and flexible production capacity.

High Cycle Time and Capacity: Mainstream equipment must achieve efficient production cycles to meet the demands of large-scale manufacturing. Optimizing workstation layout and equipment configuration can further shorten production cycle times.

Flexible Production and Rapid Changeover: The modular design allows for easy addition and removal of functional modules to accommodate diverse product requirements. Furthermore, the intelligent parameter switching system automatically calls assembly programs for different products, significantly reducing changeover time.

III. Common Equipment Types and Functional Analysis

Automatic rotor assembly equipment comes in a wide variety of types, each with its own distinct functions. The following are some common equipment types and their functional analysis:

1. Rotor Magnetization and Insertion Machine: This machine performs a series of processes, including press-fitting the rotor shaft, inserting magnets, weight removal and balancing, dynamic balancing measurement, magnetization, and assembly of the inner and outer rotors. Its high accuracy and efficiency have led to its widespread application in fields such as new energy vehicle motors and industrial servo motors.

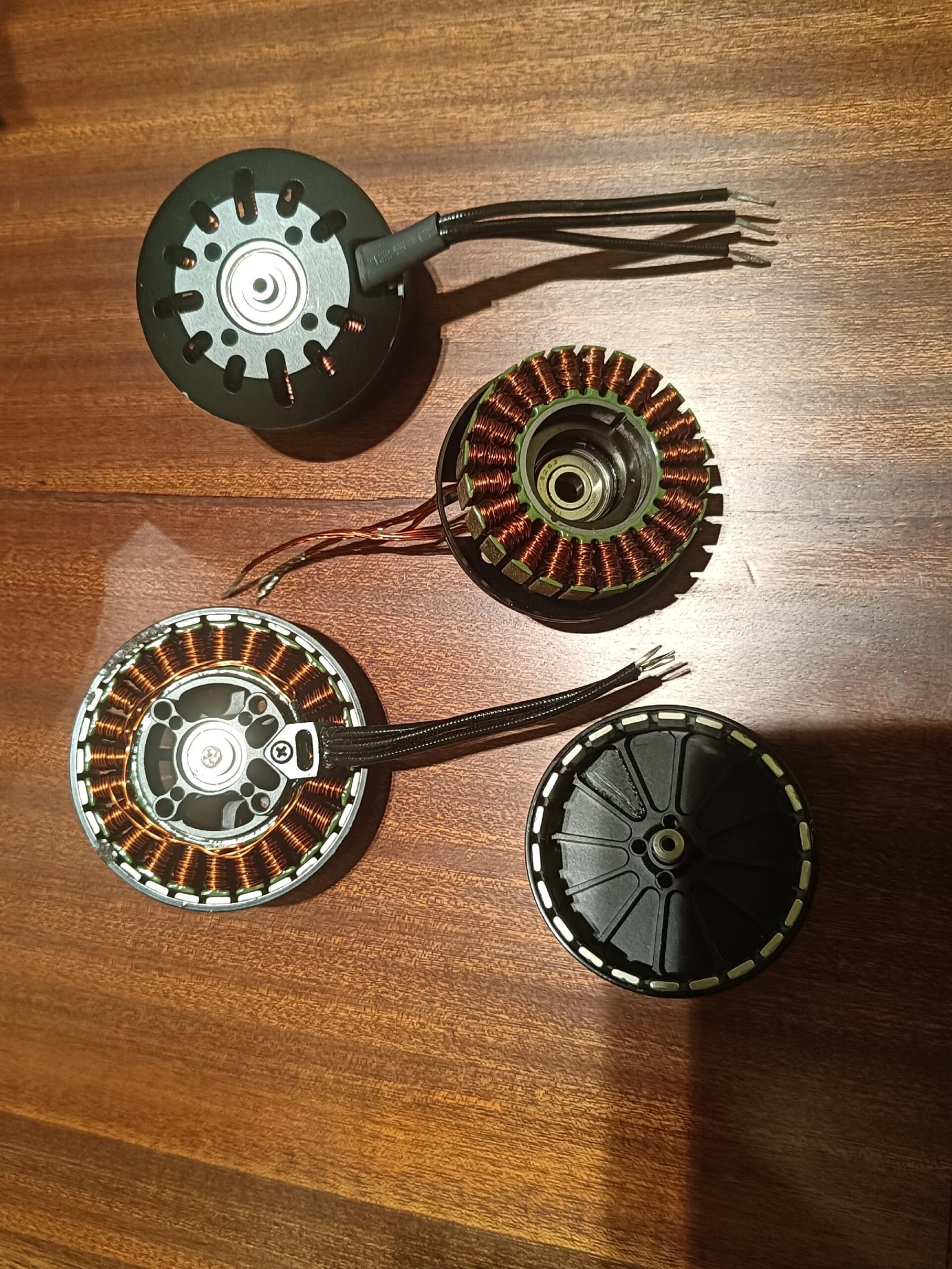

2. Double Flying Fork Rotor Winding Machine: Its double flying fork structure enables high-speed winding, supporting single or multiple wires. Its highly accurate winding tension control and wire routing precision give it significant advantages in applications such as drone motors and high-speed hair dryer motors.

3. Dynamic Balancing Machine: This machine rotates the rotor at high speed and adjusts balance using laser weight removal or weight addition. Its high accuracy and rapid correction capabilities have made it widely used in applications such as automotive EPS motors and power tool motors.

IV. Technology Trends and Industry Practices

With the continuous advancement of technology, automatic rotor assembly production equipment is also undergoing continuous upgrades. The following are some current technology trends and industry practices:

AI-Enabled Quality Control: Through machine learning analysis of assembly data, equipment failures can be predicted and process parameters optimized. This intelligent quality control approach significantly improves production efficiency and product quality.

Digital Twin Technology: Simulating the assembly process in a virtual environment can proactively identify interference or collision issues, shortening equipment commissioning cycles. This technology allows equipment to be fully verified and optimized before production begins.

Green Manufacturing: Utilizing low-energy servo motors and energy recovery systems reduces energy consumption, aligning with carbon neutrality goals. This environmentally friendly production method not only contributes to sustainable business development but also helps protect our planet.

Lini Produksi Kumparan Stator Motor BLDC

In summary, automated rotor assembly equipment continues to evolve and advance in terms of precision, efficiency, equipment types, and technological trends. Vacuz hopes this information is helpful to you!

Email: sales@vacuz.com