With the continuous development of science and technology, motor winding equipment gradually intelligent, many friends for the winding machine configuration is not very well understood, for example, a concern: automatic winding machine with servo motor or stepper motor is good?

In fact, it is not absolute, some winding machines with servo motors, there are also winding machines only need stepper motor can be, the details of how the following: 1.

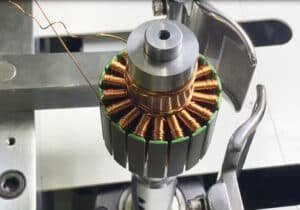

1. If the winding precision requirements are higher, you need to match the servo motor, because the servo motor control is more accurate, of course, the winding effect will be better. There is no requirement for precision, the stator is also a more conventional product, you can match the stepper motor.

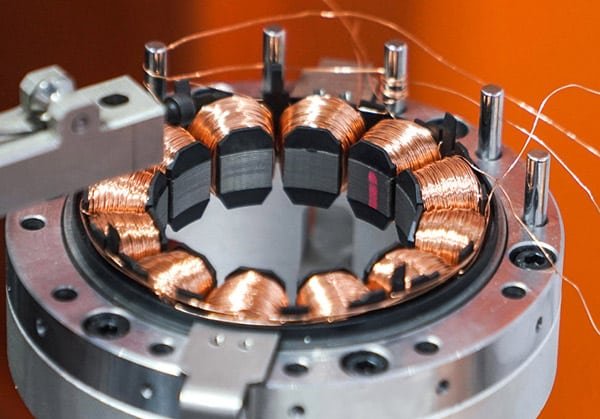

2. Inner winding products often with servo motors, because the inner winding machine technology is more precise, with a higher degree of cooperation; simple external winding products do not require high, you can match the stepper motor, can achieve ordinary winding on it.

3. For high speed requirements, you can use servo motor, servo motor for speed control is more accurate and easy; general requirements of the product, you can use stepper motor.

4. Some shaped products, oblique groove, large wire diameter, large outside diameter and other winding more difficult stator products, it is recommended with a servo motor, compared to the stepper motor, more accurate control.

Automatic winding machine with servo motor or stepper motor is good? The above has made a simple explanation, mainly depends on the needs of their own products, if the requirements are high, try to use servo motors, requirements are not high can use stepper motors, do not blindly pursue the configuration, because the configuration is high, all aspects of the requirements and prices will be higher, so that the loss is not worth the gain.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]