Fully automatic fly fork external winding machines are widely used winding equipment, often used for brushless stators. They offer high winding speed, tight winding, and consistent winding quality. So, what are the configuration and requirements for a fully automatic stator fly fork external winding machine? What should be considered when choosing one? Vacuz will give you a brief introduction below!

I. Core Configuration Requirements

1. Mechanical Structure and Transmission System

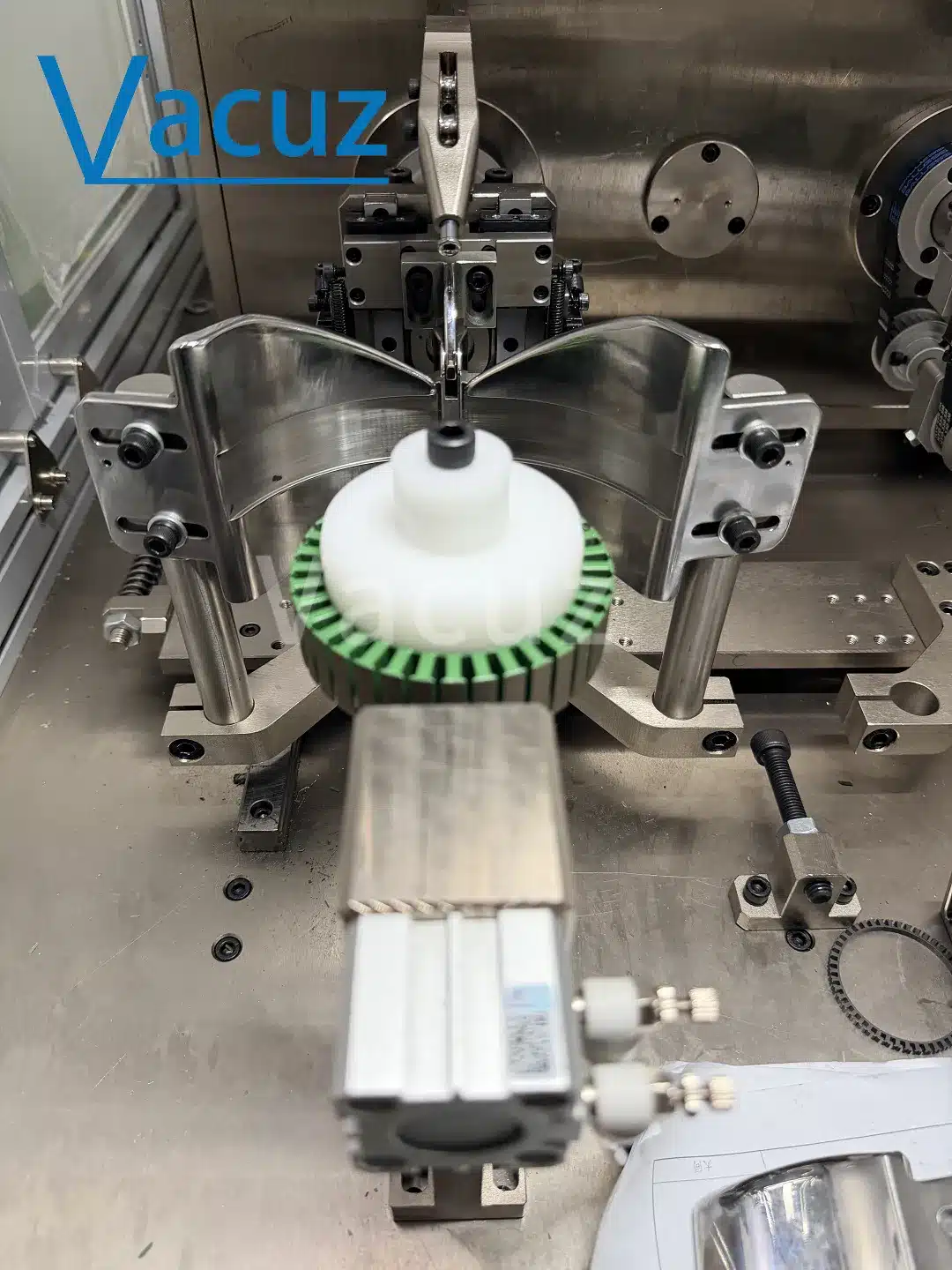

Fly Fork Structure: Adopts a single or double fly fork design. The fly fork must be equipped with ceramic wire tips (wear-resistant and with stable conductivity), and its forward and backward movement is achieved through springs, working in conjunction with the guard plate to complete the coil winding.

Servo Control System: A transmission chain consisting of precision guide rails, ball screws, couplings, and cylinders ensures that the fly fork positioning error is ≤±0.1mm. A servo motor drives the fly fork to rotate, while the indexing system controls the stator slot switching time to ≤0.1 seconds.

Multi-Station Design: Supports 1/2/4-station synchronous operation. The winding time for a single station can be reduced to 8 seconds, with a daily output of 2000 units. For example, the Vacuz external winding machine uses modular fixtures, requiring only 10 minutes for changeover.

2. Electrical and Control Systems

PLC Main Control System: Integrates parameter storage, allowing preset parameters such as number of turns, direction, and wire cutting angle, and supports one-click changeover. For example, the Vacuz external winding machine has a step sequence memory capacity of 999 sets, adapting to complex winding processes.

Tension Control System: Dynamically compensates for wire tension fluctuations, with a tension range of 0.5-1.5N for fine wire (≤0.1mm) and 2-5N for thick wire (≥0.3mm), eliminating tension differences in conjunction with a hysteresis brake.

Human Machine Interface (HMI): Displays tension curves, fault alarms, and production data in real time, supporting data traceability and remote debugging.

3. Automation Functions

Full-Process Automation: Integrates automatic feeding, winding, wire arrangement, wire cutting, clamping, and unloading functions, reducing manual intervention by more than 60%. For example, the Vacuz equipment only requires manual material handling, making operation simple.

Non-standard customization capabilities: For stators with large outer diameters, thick wire diameters, and high stack thicknesses (e.g., stator outer diameter ≤ Φ140mm, stack thickness 0-40mm), customized molds and wire routing solutions are provided.

II. Key Selection Points

1. Performance Parameter Matching

Winding speed and accuracy: Select the speed range (e.g., 0-4500rpm) and repeatability (±0.02mm) according to product requirements. High-speed models (e.g., Vacuum machines) are suitable for thin wire winding, while low-speed stable models (Vacuz machines) are suitable for thick wires or complex structures.

Wire diameter compatibility: Confirm the wire diameters supported by the equipment (e.g., Φ0.08-1.2mm) to avoid wire breakage or damage due to out-of-range use.

Stator size compatibility: Check the equipment’s coverage of stator outer diameter, inner diameter, and stack thickness (e.g., outer diameter ≤ Φ140mm, stack thickness 0-40mm) to ensure matching with product specifications.

2. Stability and Reliability

Core Component Quality: Prioritize equipment using imported servo motors, high-precision ball screws, and wear-resistant guide rails to reduce failure rates. Vacuz winding machines utilize precision ball screws for high operational stability.

Heat Dissipation and Protection Design: High-efficiency cooling systems are required for prolonged high-speed operation to prevent motor overheating; protection ratings must reach IP54 or higher to prevent dust intrusion.

3. Usability and Maintainability

User-Friendly Interface: The HMI interface should be simple and intuitive, supporting multi-language switching and quick parameter adjustments. For example, Vacuz equipment offers Chinese/English interfaces, lowering the operational threshold.

Maintenance Convenience: Modular design facilitates quick replacement of wear parts (such as nozzles and tensioners), reducing downtime. Vacuz winding machines use quick-release fly forks, improving maintenance efficiency by 30%.

4. After-Sales Service and Technical Support

Response Speed: Select manufacturers offering 24-hour online support and on-site service within 48 hours to ensure timely troubleshooting.

Spare Parts Supply: Confirm the manufacturer’s ability to provide key spare parts (such as servo motors and PLC modules) long-term to avoid maintenance difficulties due to production stoppages.

Training Services: Request the manufacturer to provide operation training and process optimization guidance to improve production efficiency. Vacuz provides systematic training to operators before equipment delivery to ensure production continuity.

5. Cost-Effectiveness and Brand Reputation

Price Comparison: Under the premise of identical functions, prioritize equipment with reasonable prices and high cost-effectiveness. Vacuz winding machines are 5%-10% cheaper than the market average, suitable for cost-sensitive customers.

What are the configuration and requirements of a fully automatic flying fork external winding machine? What should be considered when choosing one? Vacuz has provided a brief explanation above; we hope this information is helpful!