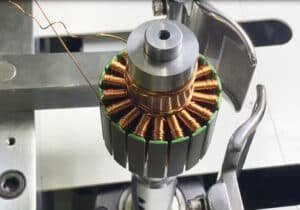

In order to adapt to the coil processing process CNC winding machine needs to be configured with spindle speed control function, winding equipment should be processed by the type of difference in its configuration also varies, we are familiar with the type of spindle motor AC motor, DC motor, servo drive motor these three categories, these motors used in the speed control mode have their own characteristics, the following winding equipment combined with the speed control mode in the equipment.

A, CNC winding machine AC motor speed control: this type of motor itself is no speed control function, it needs to be electromagnetic speed control device or add a frequency converter to achieve speed control function, in the winding equipment we are more common is the frequency converter speed control mode, through the control system of the winding equipment control frequency converter so that the motor has a speed control function, the way also has a certain role in energy saving.

Second, the DC motor speed regulation: DC motors need to supply power into DC power to drive the motor operation, magnetic ring winding machine so DC motors are configured with DC speed control board or brushless driver to drive the control motor, due to the small size of the motor in small winding equipment in the larger amount of applications.

Terzo, il controllo della velocità del motore servoassistito: appartiene alle parti mobili di precisione per le apparecchiature di avvolgimento ad alta precisione, con un driver speciale per ottenere il controllo del funzionamento ad anello chiuso; la caratteristica principale di questo tipo di motore è la coppia costante, il funzionamento ad anello chiuso, utilizzato per soddisfare i requisiti di lavorazione delle bobine ad alta precisione.

The purpose of filling the linear guide with lubricant is to prevent the metal contact between the track surface and the rolling body inside the linear guide, etc., to reduce friction and wear, and to prevent heating and sintering. When the rail surface and rolling body of the rolling contact surface to form the composition of the oil film, also has the effect of reducing the contact stress due to the load. Management of lubrication work, the adequate formation of oil film to ensure the reliability of the linear guide stranding machine is very important.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility”” class=”” id=”"][/fusion_form]