Brushless motor stator winding is an indispensable part of motor production, and now often use professional equipment to solve the winding problem, so what are the common stator winding solutions? Vacuz gives you an introduction, I hope it can help you!

There are two kinds of common brushless stator winding, one is the flying fork winding, belongs to the external winding type, the other is the needle winding, belongs to the internal winding type, according to the complexity of the stator parameters, and divided into different models of equipment, including common equipment as well as non-standard equipment.

1. Flying fork external winding, ordinary equipment is relatively simple, winding method is also relatively simple, mainly for the slot outward brushless stator, such as models, drones, fascia guns, cooling fans and other small stator products. If you encounter winding thick wire, or precision lineup requirements, the equipment configuration requirements are also correspondingly higher.

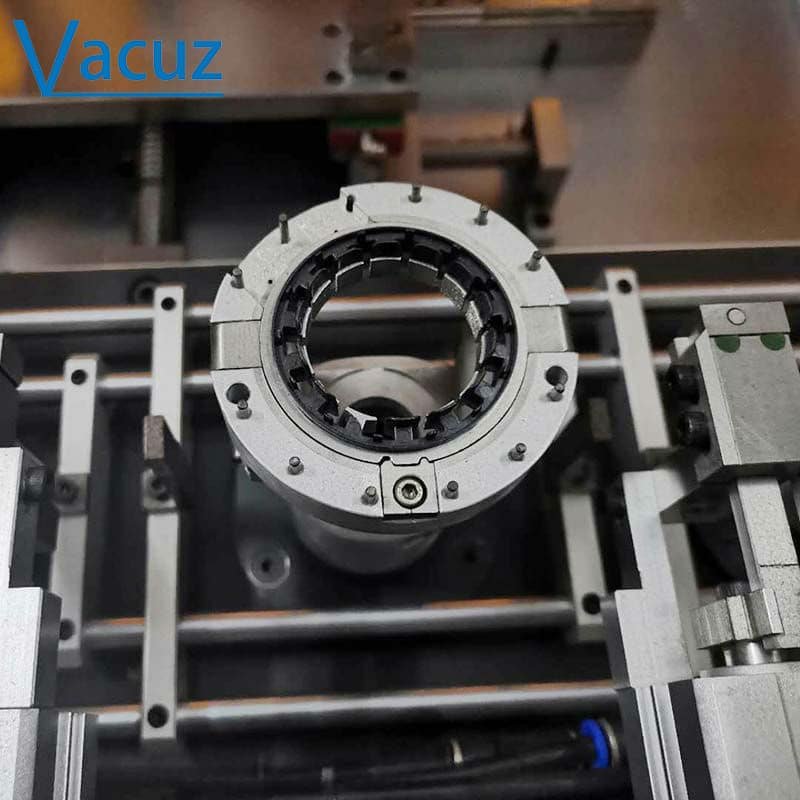

2. Needle winding, generally configured with special servo motor and drive controller, mainly for brushless stator with inward slot, such as small pumps, blowers, electric toothbrushes, electric tools and other brushless stator products. If you encounter multi-line, thick line, precision line demand, the configuration requirements may be higher.

In fact, whether it is external or internal winding, winding should be done in accordance with the requirements, parameters need to be adjusted correctly, the speed should not be too fast, to avoid injury, wire breakage, jumping and other undesirable situations, to ensure that the winding is stable and normal.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility”” class=”” id=”"][/fusion_form]