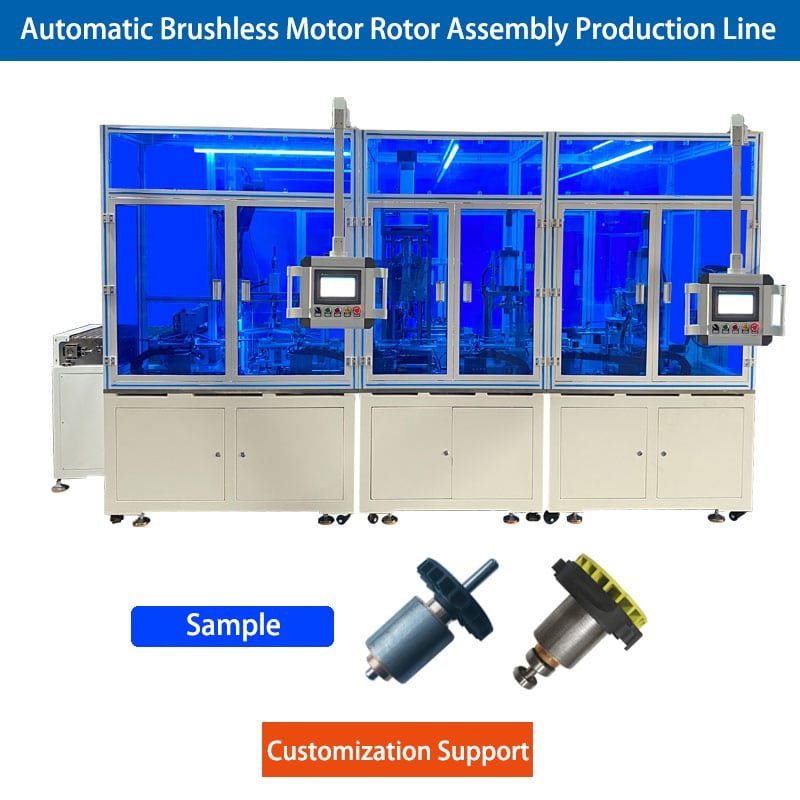

Brushless motor rotor assembly requires the use of an automated production line. This can significantly improve production efficiency and product quality, while reducing the possibility of poor manual handling. The use of dynamic production line can also reduce production costs, so that the product more competitive advantage. Vacuz gives you an overview of the specific aspects!

1. high degree of automation of the production line, with high efficiency, high qualification rate and product quality stability and other characteristics;

2. can trace the production of any batch of workpieces, so that the production process can be controlled and traceable, and has the report function, can meet the production requirements of the demand side;

3. Adopting visual inspection system to detect whether the insulators are installed, whether the installation size meets the standard and whether the core direction is correct;

4. Adopting double clamping jaw design to switch the way of loading and unloading, which saves the time of loading and unloading and greatly improves the efficiency of the equipment;

5. Adopting automatic production line, many processes are replaced by manual labor, which reduces manual labor intensity, improves the image of the factory and also solves the problem of recruitment difficulties.

The above is the brushless motor rotor automation production line functional requirements and application advantages, master these small details, help to better understand the motor production related knowledge.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility”” class=”” id=”"][/fusion_form]