Automatic winding machine winding skills and attention to detail in the work

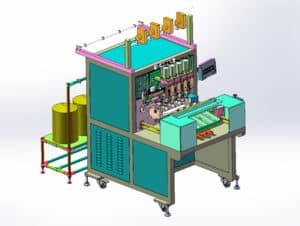

Automatic winding machine is useful to improve the efficiency! The improvement of the automatic processing ability of the winding machine is known to all users. Various high-end sensors, high-precision transmission components, servo systems and other fine components continue to be used in the control of winding machines.

CNC winding machine control system is now widely used in the field of Z. With automatic lineup function, it can be seen in the winding process of all kinds of coils. The system integrates the functions commonly used in the winding process. The control circuit integrates the control and signal input of the equipment, and the system can also be equipped with random differential for its use. The wire sheave is the mechanism in the structure of the winding machine that is in direct contact with the enameled wire. There are certain differences in the pulley structure for different types of wire. Our common winding skills are flat wire, single stranded round wire, multi-stranded round wire, etc. Vacuz will introduce the use of wire sheaves for these three types of winding process equipment below.

The slot shape of the flat wire wheel is mainly rectangular or rectangular, and the width and thickness of the guide wheel are greater than the customary wire wheel. Because the winding section of flat wire in the winding process is mainly rectangular, thus the gap between the slots can be adjusted according to the different wire diameters. When winding a single round wire, the V-shaped guide wheel is generally used, and the wire can be usefully guided in the V-slot. The standard equipment of many automatic winding machines is generally V-type guide wheel. The winding of multi-stranded round wire requires one enameled wire, thus its equipment is more special and requires U-type guide wheel.

Different winding machines have different winding processes, and so do the wire wheels. Different types of wire wheels have certain differences in raw materials. Metal, nylon, copper and aluminum materials are commonly used for wire reels, and some special wire reels are special.

The role of the central part of the winding machine manipulator.

The controller is the central part of the winding machine and plays an important role. Together, the performance of the component also determines the working performance of the winding machine. The controller is the brain of the winding machine and is responsible for the control of power supply, lineup, etc. The controller is responsible for the overall operation and control of the winding machine and the power supply of some parts. If it is disturbed by unstable power grid, it is easy to present black screen, component loss of control, and dead machine. Therefore, our workshop should provide special power supply and other methods to ensure the power supply of the winding machine, so that the winding machine can run better production operation. The normal operation of the winding machine requires the support of a variety of elements, of which the power supply is a very important part.

As we all know, the winding machine is a fine equipment, widely used in transformer manufacturers. There are strict requirements for the production environment and processing technology. As mentioned earlier the operation of a winding has a great impact on the power of the motor. There are two kinds of winding machine manipulators commonly used nowadays. One is the general-purpose manipulator provided by the integrated supplier, and the other is the manipulator developed by the manufacturer. The common problems of the manipulator are the strong power control part and the buttons. These problems cannot be solved by the user, and the manufacturer needs to be notified for repair. Inverter problems are also relatively common, you can check the inverter display interface to determine the fault, motor problems users should pay attention to the motor in the process of use of abnormal noise, temperature rise is normal, to suspend the equipment in the process of overload operation; brake is a wear parts, in the winding machine should be adjusted in a timely manner after a period of time, if necessary, replace.

Electrical control system is not set properly caused by the fault.

Improperly set up system is a soft fault. Winding machine has a set of chaotic control system and control procedures. Improper settings can also lead to problems. Users should understand the key in the manual before using the winding machine. Common improper settings include wrong winding direction, winding width more than the equipment plan, wire diameter and winding machine speed mismatch, step unit fault, etc. Now many manufacturers provide operation training, users should send someone to learn, to avoid the problem of winding machine not set after changing the winding process.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility”” class=”” id=”"][/fusion_form]