Flying fork winding machines are a great help to the stator industry. They are commonly used for stators with outward-facing slots. However, different manufacturers’ winding machines vary in their usage, including differences in various components and configurations. So, how can an automatic flying fork stator winding machine operate stably and smoothly? What factors affect its performance? Below, Vacuz will give you a brief introduction!

I. Core Hardware Optimization: Laying the Foundation for Stable Operation

1. Transmission System Precision

High-precision ball screws (error ≤ ±0.005mm/year), linear guides, and couplings are used to reduce mechanical backlash and avoid wire routing deviations.

Regularly check the wear of the ball screws to ensure that the transmission components have a lifespan of over 100,000 hours.

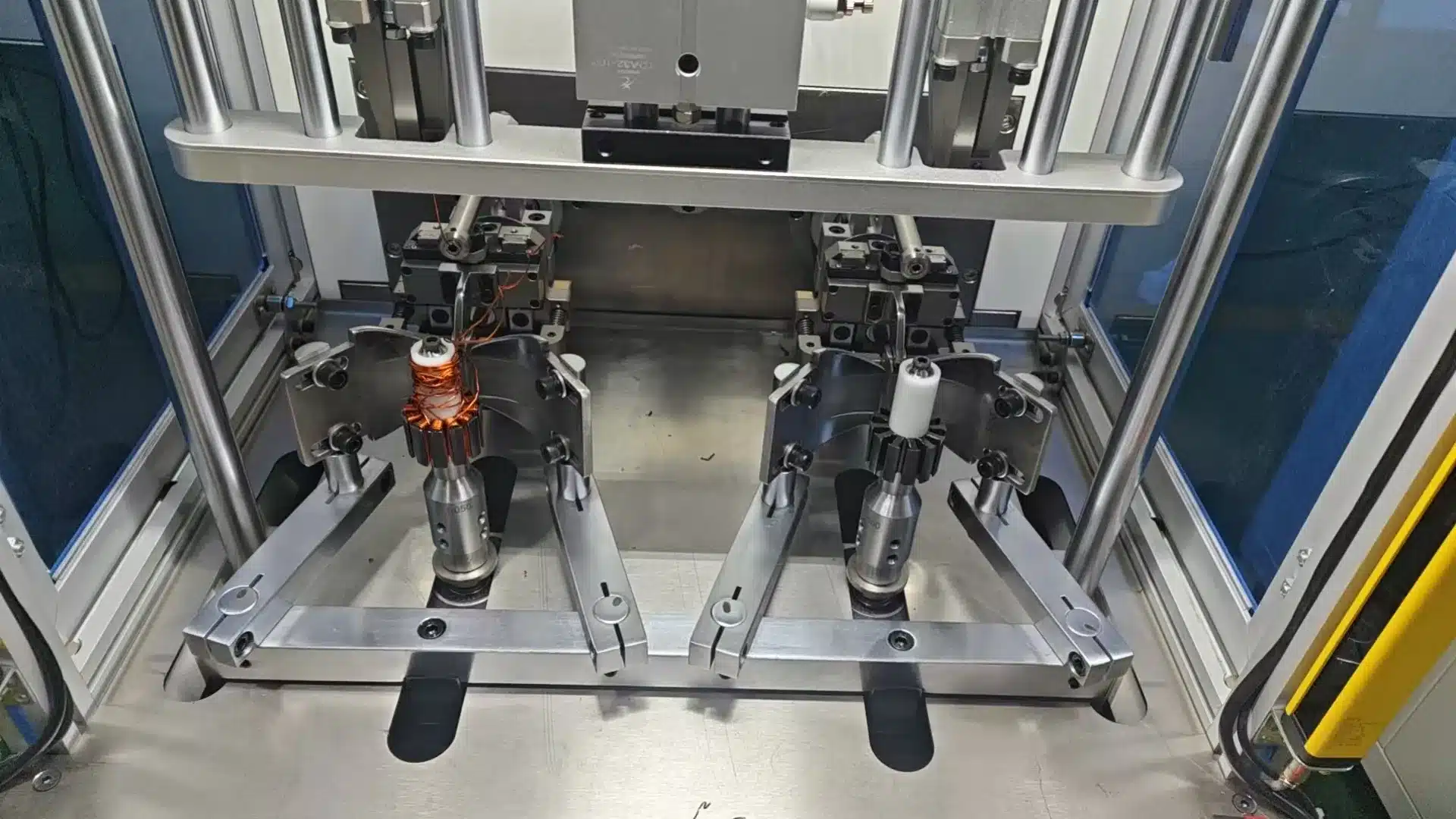

2. Flying Fork Dynamic Balancing

The flying fork design requires sufficient rigidity and light weight, and dynamic balancing correction (error ≤ ±0.01mm) is used to reduce vibration during high-speed rotation (≥2500r/min).

The flying fork trajectory is calibrated quarterly using a laser interferometer; adjustments are required when the deviation exceeds 0.01mm.

3. Die Head and Guard Plate Coordination

The die head is equipped with a flexible die tongue that adapts to the stator slot size, with a feed error ≤ ±0.02mm, ensuring accurate insertion of the enameled wire.

The guard plate surface is mirror-polished (friction coefficient ≤ 0.1), reducing wire resistance and preventing wire damage or breakage.

II. Electrical and Control Systems: Achieving Accurate Coordination

1. Servo Closed-Loop Control Technology

Through a bus-type PLC motion controller and servo motor coordination, dynamic matching of the fly fork speed and die head feed speed is achieved, resulting in high-efficiency response.

Multi-station independent servo drive design, with a phase synchronization error ≤ ±0.5°, ensures consistent winding start points at each station.

3. Intelligent Tension Control

Electromagnetic tensioners combined with a PID algorithm are used, with tension fluctuation range ≤ ±2% (or ±0.5N, depending on the specific design).

Dynamically adjust tension according to wire diameter:

Fine wire (e.g., 0.1mm): Tension 2~3N, automatically reduced by 10%~15% during high-speed winding.

Thick Wire: Prevents excessive tension from damaging the wire.

4. Real-time Monitoring and Fault Prediction

A sensor network collects parameters such as tension, speed, and position (sampling frequency ≥1kHz) and generates data curves.

Based on machine learning algorithms, historical data is analyzed to establish a fault model and predict issues such as tensioner wear and servo motor overheating.

III. Process Parameter Optimization: Adapting to Diverse Needs

1. Winding Speed and Tension Linkage

At high-speed winding (≥2000r/min), the system automatically reduces tension by 10%~15% to prevent wire breakage.

Segmented speed control: Low speed during the initial winding stage (ensuring wire end fixation), increasing speed during the constant speed stage.

2. Wire Laying Algorithm Optimization

High-frequency laying reduces the single laying distance and minimizes motion impact.

A vision inspection system is introduced to correct laying deviations in real time, preventing wire overlap or uneven gaps.

3. Wire Management

Pre-processing and inspecting the enameled wire reduces frictional resistance.

Equipped with a laser diameter gauge to monitor wire diameter changes in real time (alarm triggered when error exceeds ±2%).

IV. Environmental Control: Reducing External Interference

1. Temperature and Humidity Management

Workshop temperature is controlled at 20±2℃, humidity ≤60% to prevent damage to electronic components or wire deformation.

A constant temperature and humidity workshop can reduce the failure rate by 40%.

2. Vibration Damping and Grounding

Vibration dampers are installed on the equipment base to suppress high-speed vibration (vibration isolation efficiency ≥90%).

Ensure good grounding of the equipment to prevent leakage or electrostatic discharge from damaging electronic components.

3. Power Stability

Install a UPS uninterruptible power supply and voltage regulator to avoid equipment damage caused by voltage fluctuations or sudden power outages.

V. Maintenance and Operation Management: Extending Equipment Lifespan

1. Preventive Maintenance Plan

Daily checks are conducted on equipment temperature, sound, vibration, and lubrication. Any abnormalities are immediately addressed by stopping the machine for repair.

Monthly full machine calibration is performed, including parameters such as the fork rotation center, die feed rate, and tension sensor zero-point drift.

Replace the wire nozzle and guard plate every 500 hours to prevent wear and uneven wire winding.

2. Operator Training

Conduct regular speed optimization training to improve parameter setting capabilities (e.g., tension-speed mapping table adjustment).

Establish a speed-quality correlation database to guide operators in adjusting process parameters according to production needs.

3. Spare Parts and Tool Management

Stock up on critical spare parts (e.g., bearings, belts, sensors) to ensure rapid replacement of faulty components.

Use professional balancing testing tools to calibrate the fly fork installation position to avoid vibration caused by installation deviations.

How can the fly fork stator automatic winding machine operate stably and smoothly? What factors affect its performance? Vacuz has provided a brief explanation above; we hope this information is helpful!