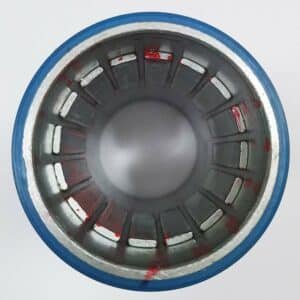

The automated production mode of rotor magnet loading needs the help of advanced equipment and process, so that the problem of rotor assembly can be solved. The automated mode instead of manual labor not only improves the production efficiency, but also the quality consistency of the product is better, the following are some of the methods of automated production, take a look with Vacuz!

1. Use automated equipment to separate, mark, check and load magnets. These equipments can automatically complete the process of magnet separation, polarity marking inspection, magnetic flux relative value inspection, etc., which greatly improves the production efficiency and quality.

2. Use automated production lines for production. Combine the magnet loading machine, automation equipment, conveyor belt, etc. into an automated production line to realize the whole process of automation from magnet sorting to loading.

3. Use machine vision technology for quality inspection. During the production process, machine vision technology is used to detect the appearance and polarity of magnets to ensure product quality.

4. Use robots to automate operations. For example, robots are used to perform operations such as gripping, placing and fixing magnets to improve production efficiency and accuracy.

5. Combine digital and intelligent technologies for production management. The production process is monitored and scheduled through a digital management platform to visualize and control the production process.

How to realize the automated production mode of rotor magnet loading not only requires the combination of advanced equipment, process and technology, but also continuous R&D and innovation to improve production efficiency and product quality.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility”” class=”” id=”"][/fusion_form]