The precision of a fully automatic stator winding machine is its core performance indicator, directly determining the winding quality, electrical performance, and overall reliability of the motor stator. Its precision is mainly reflected in winding accuracy, repeatability, motion control accuracy, and system stability. Improving precision requires comprehensive improvements from multiple dimensions, including mechanical structure optimization, control system upgrades, process parameter adjustments, and environmental control. Below, Vacuz will analyze this in detail:

I. Manifestations of Precision in Fully Automatic Stator Winding Machines

1. Winding Accuracy

Coil Parameter Control: Precision winding machines can accurately control parameters such as the number of turns, layers, wire spacing, and position of the coil, with an error range typically controlled within ±0.01mm.

Coil Arrangement Consistency: The coils are arranged tightly and uniformly, avoiding problems such as decreased motor performance due to loose arrangement or coil breakage and short circuits caused by localized stress concentration.

2. Repeatability

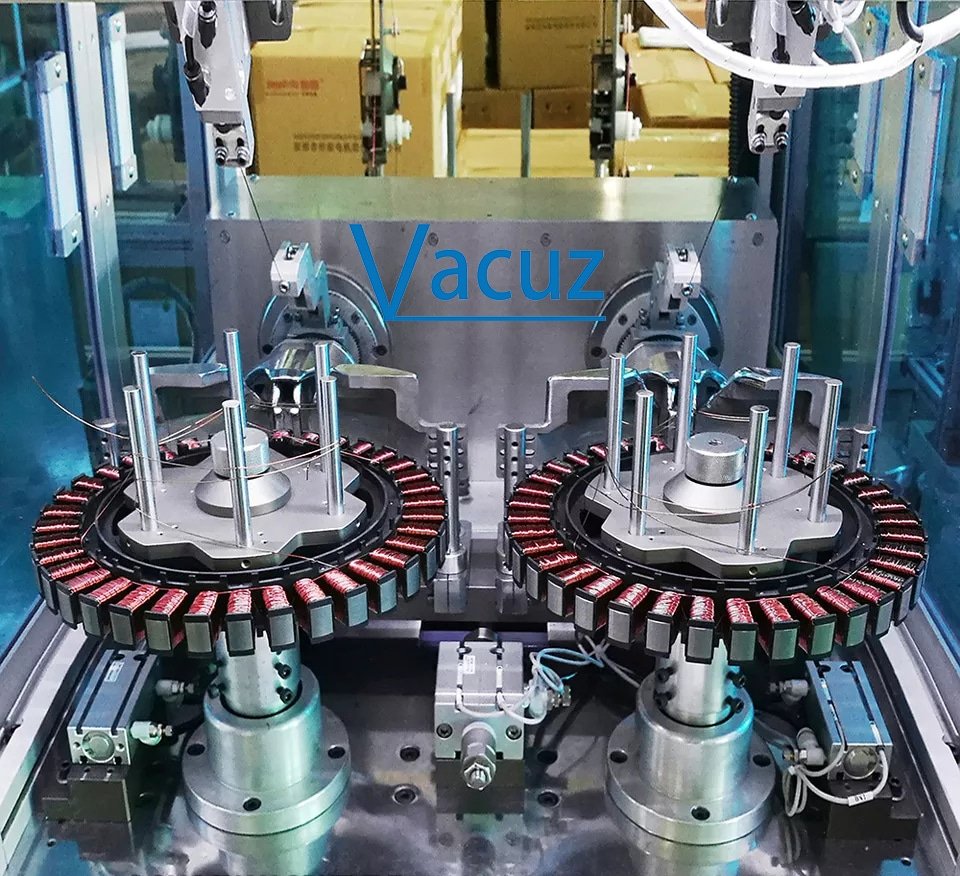

Multi-Station Collaboration: In multi-station winding machines, each station must maintain a high degree of consistent positioning accuracy to ensure that the coil parameters wound at different stations are completely identical. For example, a six-station internal winding machine requires micron-level positioning compensation via high-precision servo motors and encoders when switching stations.

Long-term stability: During long-term operation, the repeatability of positioning accuracy must remain stable to avoid accuracy degradation due to mechanical wear or thermal deformation.

3. Motion control accuracy

High-speed motion stability: At high-speed winding speeds (e.g., above 1000 rpm), the equipment must maintain smooth movement to avoid winding errors caused by vibration or inertia.

Dynamic response capability: The equipment must respond quickly to control commands, accurately executing acceleration, deceleration, and reversing actions to avoid winding parameter deviations due to insufficient dynamic response.

4. System stability

Anti-interference capability: The equipment must be able to resist environmental factors such as electromagnetic interference and temperature fluctuations to ensure stable operation in complex industrial environments. For example, measures such as shielded cables and isolation transformers are used to reduce electromagnetic interference, and a temperature control system is used to maintain stable equipment temperature.

Fault Self-Diagnosis and Compensation: Precision winding machines are typically equipped with a fault self-diagnosis system, which can monitor the equipment status in real time and automatically adjust parameters or stop the machine when abnormalities occur, preventing accuracy loss due to escalating faults.

II. Methods to Improve the Accuracy of Fully Automatic Stator Winding Machines

1. Optimize Mechanical Structure Design

Select High-Precision Components: Employing high-precision servo motors, guide rails, lead screws, belts, and other key components ensures accurate motion transmission. For example, using ball screws instead of trapezoidal lead screws can significantly improve positioning accuracy and repeatability.

Reduce the Mass of Moving Parts: Reducing the inertia of moving parts and improving dynamic response capabilities through optimized structural design (such as using lightweight materials and hollow shafts).

Increase Mechanical Rigidity: Improving mechanical rigidity by strengthening the equipment frame and optimizing the support structure reduces the impact of vibration and deformation on accuracy.

2. Upgrade the Control System

Employ a High-Precision Servo Drive System: Selecting servo motors and drivers with fast response speeds and high control precision achieves micron-level positioning control.

Optimized Control Algorithms: By improving PID control algorithms and introducing advanced algorithms such as feedforward compensation or fuzzy control, the system’s adaptability to dynamic changes is enhanced.

Integrated Intelligent Sensors: High-precision sensors (such as tension sensors and position sensors) are installed at key locations (e.g., winding ends, tensioners) to monitor winding parameters in real time and feed them back to the control system, achieving closed-loop control.

3. Fine Adjustment of Process Parameters

Tension Control: Tension is accurately adjusted according to wire diameter and winding speed to avoid wire stretching and deformation due to excessive tension or coil slack due to insufficient tension.

Winding Speed Matching: The winding speed is rationally set according to wire diameter and equipment performance to avoid inertial errors due to excessive speed or production efficiency losses due to insufficient speed.

Winding Path Planning: By optimizing the winding path (e.g., using spiral winding, layered winding, etc.), wire friction and deformation are reduced, improving winding quality.

4. Improve Environmental Conditions

Temperature Control: Install a temperature control system (such as air conditioning or heaters) around the equipment to maintain a stable ambient temperature and prevent thermal expansion and contraction of mechanical parts due to temperature fluctuations from affecting accuracy.

Vibration Isolation: Mount the equipment on a vibration-damping base to reduce the impact of external vibrations.

Dust and Pollution Prevention: Keep the environment around the equipment clean to prevent dust, oil, and other impurities from entering the equipment and affecting the lubrication and accuracy of moving parts.

5. Regular Maintenance and Calibration

Regular Inspection and Replacement of Wear Parts: Regularly inspect the wear of key components such as guide rails, lead screws, and belts, and replace worn parts promptly to maintain accuracy.

System Calibration: Regularly calibrate the equipment (such as position calibration and tension calibration) to ensure that all parameters are in suitable condition.

Software Upgrade: Update the equipment control system software in a timely manner, fix known vulnerabilities, and optimize the control algorithm to improve system stability and accuracy.

How is the precision of a fully automatic stator winding machine reflected? How to improve the precision of a winding machine? Vacuz has provided a simple explanation above, and we hope this information is helpful!