The choice of winding machine equipment is very important, generally need to see the customer stator sample pictures, according to the stator parameters as well as a comprehensive assessment of the winding diagram, to determine what to do with the winding machine, so as to ensure that the equipment meets the requirements, then how to choose the right winding machine equipment based on the specific stator parameters and winding diagram? Here Vacuz to introduce it!

You have given very detailed consideration to the stator parameters and winding diagrams to select the winding machine equipment, covering a number of key aspects. Next, I offer you some specific suggestions to help you better apply these considerations in practice:

First, the stator slot direction

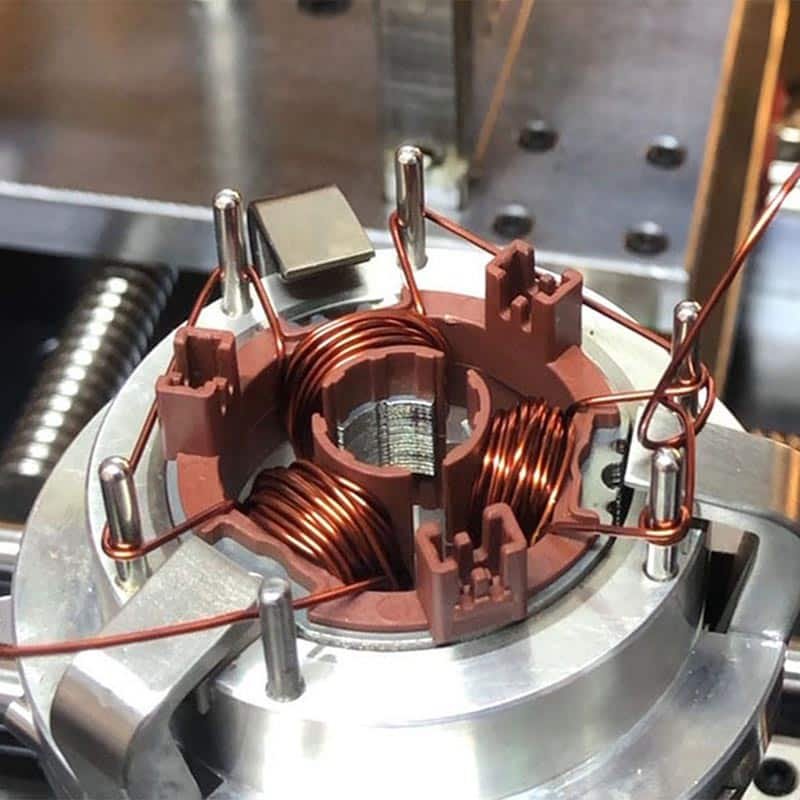

1. Inside winder equipment: For stator with inward facing slots, this equipment is usually able to control the winding process more accurately and ensure tight coil alignment.

2. Flying Fork Outer Winding Machine: For stator with outward slots, Flying Fork Outer Winding Machine is able to flexibly adapt to different winding needs and improve production efficiency.

Stator outer diameter and inner diameter

1. Choose the right size of winder: Make sure the outer and inner diameter range of the winder can cover your stator size to avoid unnecessary trouble during the winding process.

2. Consider customized options: If there is no suitable equipment in the market, you can consider customizing the winding machine to meet the winding needs of a specific stator size.

III. Stator Stack Thickness (Height)

Ensure that the winding machine adapts to the range: When choosing a winding machine, special attention should be paid to its adapted stack thickness range, to ensure that the equipment is able to handle your stator stack thickness, to avoid problems during the winding process.

Fourth, enameled wire diameter size

Select the number of stations according to the wire diameter: for the thicker enameled wire, choose single-station or double-station equipment can better control the winding speed, reduce the injury of the wire; and for the finer enameled wire, you can choose multi-station equipment to improve production efficiency.

Fifth, the requirements of the winding diagram

Selection of high-accuracy winding machine: For winding diagrams that require precise alignment, it is important to select a winding machine with high accuracy and stability to ensure that the coils are neat and tight.

Other considerations

1. Automation and Intelligence: Consider choosing a winding machine with automation and intelligence functions, such as automatic wire feeding, automatic detection and other functions, in order to improve production efficiency and reduce labor costs.

2. Maintenance: Choose the winding machine that is easy to maintain and repair, which can reduce the maintenance cost and prolong the service life of the equipment.

3. Cost-effective evaluation: based on the comprehensive consideration of equipment performance, price, after-sales service and other factors, choose the most cost-effective winding machine equipment.

How to choose the right winding machine equipment according to the stator parameters and winding diagrams? Vacuz has done a simple explanation of the above, I hope that this little knowledge can help you!

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility”” class=”” id=”"][/fusion_form]