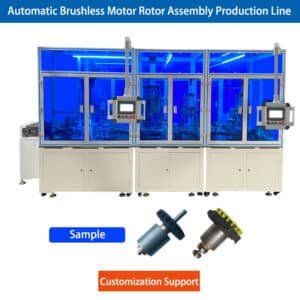

The production of automotive water pump motor is very important, common as the stator and rotor assembly production, rotor assembly more than with a specially customized intelligent production line, then how to design the automotive water pump motor rotor production line? What are the common advantages? The following Nuoyuan briefly to introduce it! Vacuz hope to help you!

Linea di produzione automatica di assemblaggio del rotore del motore brushless

Automotive water pump motor rotor production line design details and advantage analysis:

First, the production line design program

1. Process flow design

a. Material preparation: Select raw materials, such as copper, aluminum, etc., based on the material requirements of the rotor, and carry out pretreatment, such as melting, cutting, etc., to ensure the quality of raw materials.

b.Profile machining: Utilize advanced CNC machine tools for profile rough machining, including turning, milling, drilling and other processes to accurately control the basic shape of the rotor.

c.Precision machining: Introducing high-precision equipments, such as CNC grinding machines, to carry out precision machining to ensure that the dimensional accuracy and surface finish of the rotor meet the high standard requirements.

d. Surface treatment: Enhance the rotor’s corrosion resistance and aesthetic appearance through sandblasting, painting and other processes.

e. Inspection: Strict quality inspection process is implemented, including dimensional measurement, thermal stability test, mechanical properties test, etc., to ensure that the rotor meets the industry standards and customer needs.

2. Equipment selection

a. Production equipment: choose advanced CNC machine tools, CNC grinding machines and other high-precision production equipment to ensure production efficiency and product quality.

b. Testing equipment: Equipped with size testing instruments, mechanical performance testing equipment, etc., to conduct comprehensive and accurate quality testing of rotors.

3. Degree of automation

a.Automation equipment: realize the automation of the production line, such as automatic feeding, automatic loading and unloading, automatic measurement, etc., to reduce manual operation and improve production efficiency and stability.

b.Intelligent monitoring: Utilizing PLC and other automation control technology, the production process is intelligently monitored and managed to ensure the smooth progress of the production process.

Second, common advantages

1. High production efficiency

a. The application of automated production line greatly reduces manual operation and significantly improves production efficiency.

b. The selection of high-precision equipment ensures the precision and consistency of product processing and reduces the scrap rate.

2. Stable production quality

a. Strict production process and testing procedures to ensure product stability and reliability.

b. Advanced production equipment and technology to ensure the consistency of product quality.

3. Flexible and adaptable

a.The flexible design of the production line can be adapted to the production needs of different models and specifications of rotors.

b.Modularized design enables the production line to be quickly adjusted to new production tasks.

4. Energy saving and environmental protection

Advanced production equipment and technology reduces energy consumption, reduces waste emissions, and meets the requirements of environmental protection.

5. Cost Reduction

a.Automated production reduces labor costs and improves equipment utilization, thus reducing production costs.

b.Strict quality management reduces scrap rate and rework rate, further reducing production cost.

Linea di produzione di motori

How is the automotive water pump motor rotor production line designed? What are the common advantages of Vacuz has been described in detail above, the design of automotive water pump motor rotor production line needs to comprehensively consider the process, equipment selection, degree of automation and other factors, in order to achieve high efficiency, high quality, low-cost production goals to meet market demand.

Email: sales@vacuz.com