Previously used more motors are brush motors, with the brushless motor technology is more and more mature, now can be said to be all over the many fields, favored by the majority of friends!

Some friends are more curious about the brushless motor stator coil, do not know how to wind up, many think it is hand-wound, in fact, hand-wound, but for batch products, you have to use equipment to solve. So what are the brushless motor winding solutions? How to choose the winding machine equipment according to the stator parameters? Vacuz give you an analysis!

Brushless motor winding solutions:

1. external winding products, that is, the stator slot outward products, such as aeromodels, gimbal stabilizers, drones, scooters, planting machines, fascia guns, cooling fans and other brushless motor stator, at present, most of the flying fork winding to solve the problem of winding, fast speed, tightly wound, can be a single line, multiple lines and winding, automatic line winding, positive and reverse rotation, automatic transposition, clamping clips, and so on.

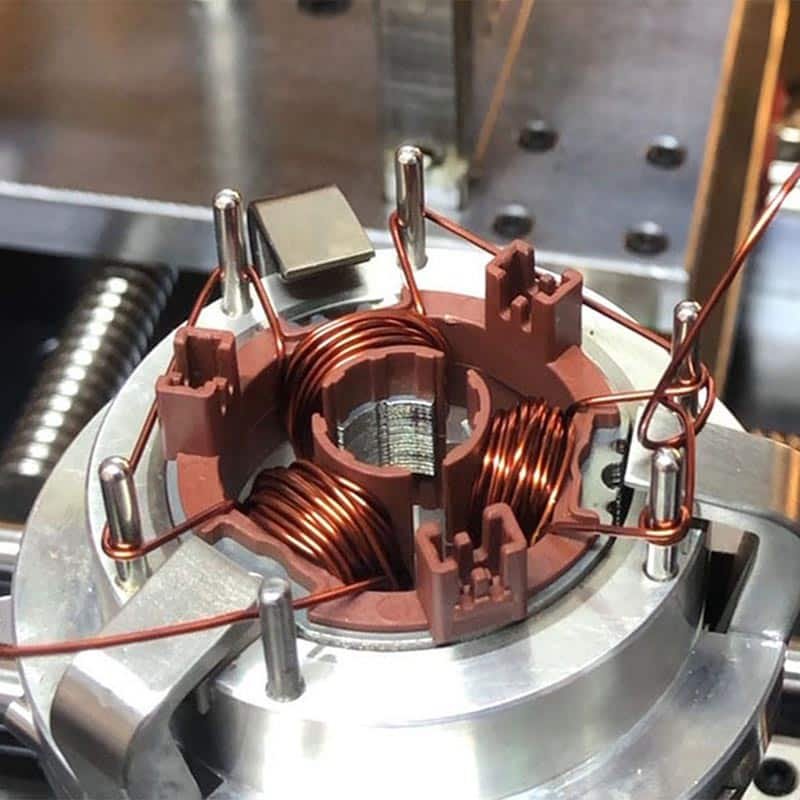

2. Inner winding products, that is, the stator slot inward products, such as power tools, household appliances, small pumps, stepper motors, rotary variable brushless motor stator, generally more than a needle winding method to solve the problem of winding, with a professional servo motor electric drive, can realize the positive and negative rotation, line close, automatic clamping and cutting and other functions.

The choice of winding equipment is very critical, mainly depends on the parameters and requirements of the stator, if the wire diameter is relatively thin, the number of turns is more, you can choose high-speed multi-station winding machine, which can improve production efficiency; if the wire diameter is thick, the winding is easy to hurt the wire, it is recommended to choose a two-position winding machine, the speed can not be too fast; if you need precision lining up, then the equipment needs to be professionally configured to ensure that the winding meets the requirements.

What are the solutions for brushless motor winding? How to choose the winding machine equipment according to the stator parameters? After reading the above, I believe you have some understanding, Vacuz hope that this knowledge can help you!

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility”” class=”” id=”"][/fusion_form]