The application of fully automatic fly fork winding machines has brought many benefits to stator winding, not only improving production efficiency but also resulting in better winding quality and effects. During the winding process, the design and processing of the fixture are crucial, directly affecting the winding quality. So, what are the design requirements for the fixtures of fully automatic fly fork winding machines? What are the processing precautions? Below, Vacuz will give you a brief introduction!

I. Core Requirements for Fixture Design

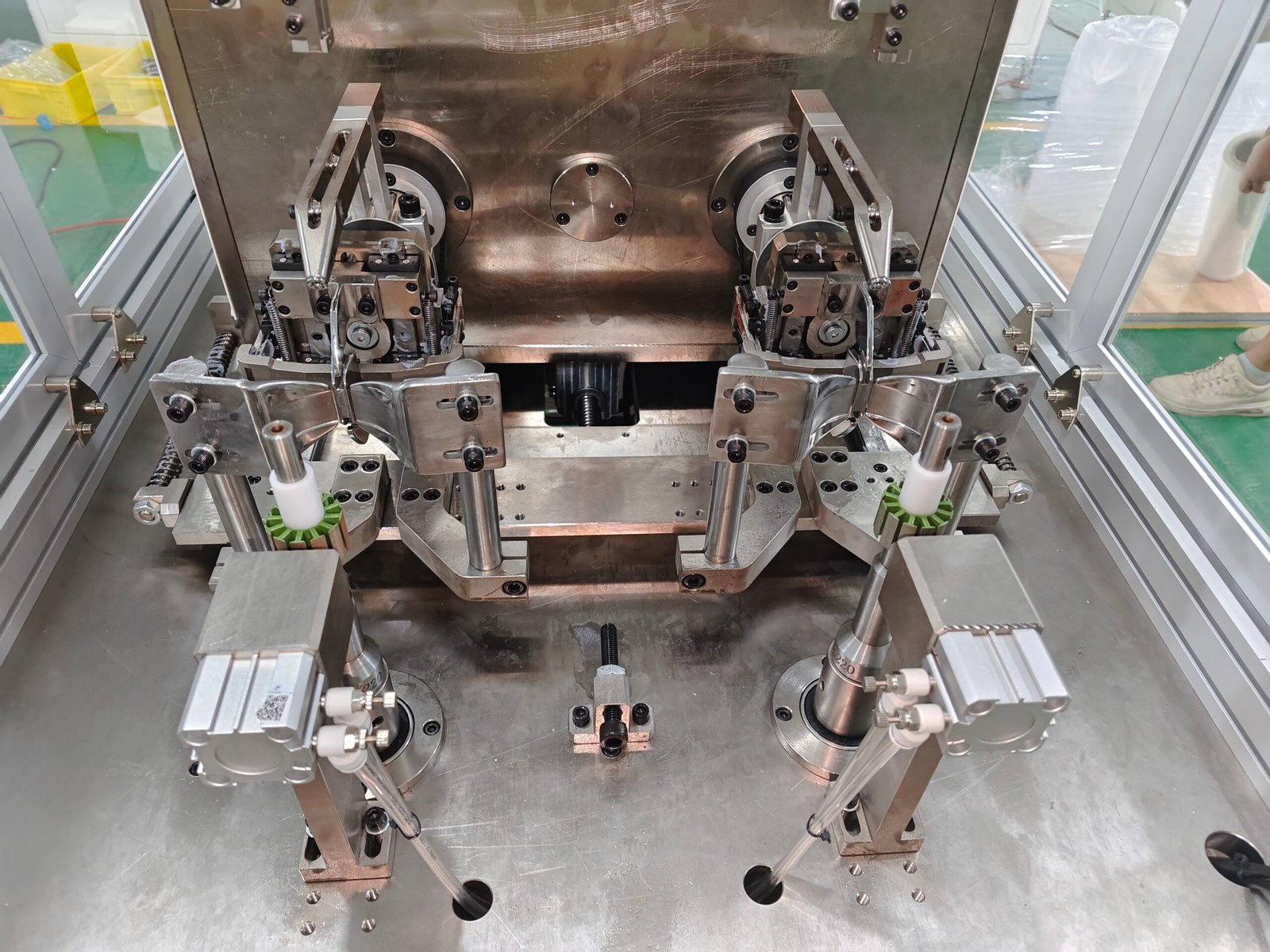

The fixtures of fully automatic fly fork winding machines must balance positioning accuracy, structural rigidity, ease of operation, and adaptability. Specific design requirements are as follows:

1. Positioning Accuracy and Stability

Complete Positioning vs. Partial Positioning: Select the positioning method based on the workpiece characteristics. For frameless torque motor stators, six degrees of freedom must be restricted to achieve complete positioning, ensuring no workpiece offset during winding. For simple workpieces, partial positioning can be used to simplify the structure.

Avoid Over-Positioning: Over-positioning may lead to workpiece deformation or uncertain positioning, and should be used with caution. However, in workpieces with low rigidity and high precision, reasonable over-positioning can improve stability.

2. Structural Stiffness and Strength

Avoid cantilever structures: Reduce the distance between stress points and support points to prevent fixture deformation. For example, fixture support points should be close to the winding area to distribute stress.

Balanced force design: Avoid unbalanced forces in the mechanism. For example, the guide rail drive force should act on the pressure center of the friction between the two guide rails to balance the torques.

Wear-resistant design: Increase wear allowance for easily worn surfaces to extend fixture life.

3. Ease of Operation and Safety

Quick changeover structure: Wear-prone parts (such as grippers and locating pins) should be designed for quick replacement to reduce downtime.

Safety protection: Fixtures should be linked to the equipment’s safety system, such as equipped with an emergency stop button to prevent accidental start-up.

Ergonomics: The fixture operating space should be ergonomic to reduce operator fatigue.

4. Modularization and Adaptability

Quick changeover design: Use modular fixtures to support quick switching between different stator specifications. For example, by changing grippers or locating blocks, it can adapt to various wire diameters and slot types. Standard Parts Selection: Prioritize the use of reliable standard parts available on the market (such as guide rails and ball screws) to reduce customization costs.

5. Special Process Adaptation

Slanted Slot Adaptation: For slanted slot stators, the fixture must be designed with an adjustable-angle wire nozzle to match the slot inclination.

Tension Control: The fixture must work in conjunction with an automatic tension system to ensure stable wire tension and prevent wire breakage or loosening.

II. Processing Precautions

During the fully automatic flying fork winding machine processing, strict control is required in three aspects: operating procedures, equipment maintenance, and safety protection. Specific precautions are as follows:

Operating Procedures

1. Strictly Follow the Procedure:

Power must be turned off when loading and unloading the frame fixture to prevent accidental start-up.

When installing the fixture, ensure screws are tightened and sleeves are in place to prevent loosening that could cause winding deviation.

The frame installation must ensure proper fit, and when hanging the wire, ensure that the wire exit does not interfere with subsequent winding actions.

2. Dynamic Parameter Adjustment:

Adjust the winding speed and tension according to the wire diameter. 3. **Troubleshooting:** Reduce speed and tension when winding thicker wire; ensure stable tension when winding thinner wire.

Design winding paths flexibly and use auxiliary tools (such as guide wheels) to reduce wire tension and bending forces.

4. **Abnormal Handling:**

In case of wire breakage, check if the wire path is clear, if the tensioner is functioning properly, and if the bobbin is intact.

After a power outage or emergency stop, reset and re-clamp the wire before restarting.

5. **Equipment Maintenance:**

Regular Inspections:

Daily inspections of clamp screws and sleeves for looseness, and check for wear on guide rails and ball screws.

Weekly inspections of the automatic tensioning system and automatic loading/unloading system.

**Critical Component Maintenance:**

Regularly lubricate guide rails and ball screws to reduce wear.

Clean sensors and monitoring equipment to ensure accurate data acquisition.

**Data Traceability:**

Establish an equipment maintenance log to record each inspection, repair, and replacement of components for quality traceability.

5. Safety Precautions

Personal Protection:

Operators must wear protective equipment (such as gloves and goggles) to prevent wire cuts or injury from flying debris.

Equipment Safety:

Ensure the equipment is properly grounded to prevent induced current from entering the control circuit.

The equipment workbench or ground must be stable and reliable, away from heat sources, magnetic sources, vibration sources, and pollution sources.

Emergency Measures:

The equipment is equipped with an emergency stop button; operators must be familiar with its location and operation.

Regular safety training should be conducted to improve operators’ emergency response capabilities.

What are the design requirements for the fixtures of a fully automatic flying fork winding machine? What are the processing precautions? Vacuz has provided a simple explanation above; we hope this information is helpful!