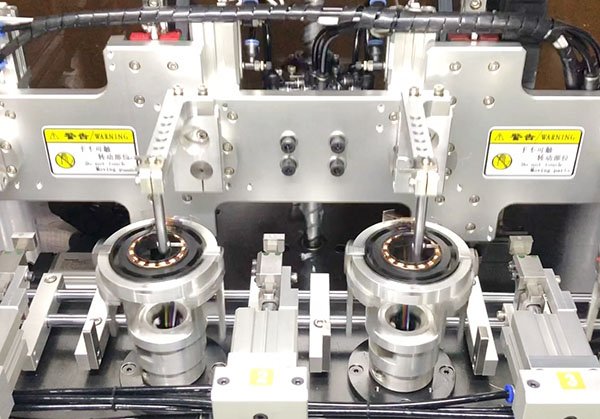

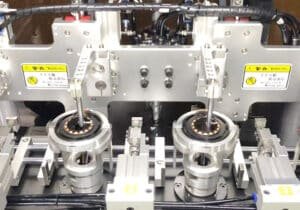

In order to adapt to different production needs, usually, automatic winding machine in the process of operation will use different fixtures as auxiliary tools, many devices and industries need to use a variety of fixtures jig, its role and benefits are mainly reflected in the following aspects.

I. Save the time of mold disassembly and installation, and improve the production efficiency.

1. When installing the fixture, it needs to be fixed on the equipment and the distance should be adjusted, and this process needs a good connection between the fixture and the equipment. In addition, it is necessary to check and inspect the mold itself, which is an important foundation for the proper use of the mold.

2. The installation and commissioning of the winding skeleton in the fixture. This process usually uses special positioning blocks or positioning, which is an important basis for testing whether the fixture is suitable for production.

2. Used to ensure the accuracy of the winding machine and product quality.

In the winding process, the relative position of the skeleton and the bobbin and the distance between the two sides ensure the space capacity, eliminating the influence of other factors and ensuring the accuracy of the product.

Third, reduce labor costs.

Most of the fixture clamping device, only a simple fixed operation or moving the handle to achieve the clamping of the skeleton, reducing the time required to adjust the position of the skeleton, and reduce the difficulty of installation . If the tooling is properly designed, calibration time is essentially unnecessary. Therefore, the use of these fixtures greatly reduces the technical requirements for personnel and reduces the work intensity, thus reducing labor costs.

Fourth, it expands the range of winding processing of the winding machine.

The winding machine can be loaded with different types of fixtures, and can also clamp different types of fixtures. The position can be adjusted by itself, and also the fixture can be used on different winding machines, which undoubtedly expands the processing range of the winding machine and eliminates the need to redesign the whole machine for coils with small parameter differences, which can reduce the investment cost and time cost of the equipment.

In summary, the use of automatic winding machine tooling fixture is very necessary, not only to change the type of fast, and simple and convenient, is a good mechanical equipment auxiliary products.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility”” class=”” id=”"][/fusion_form]