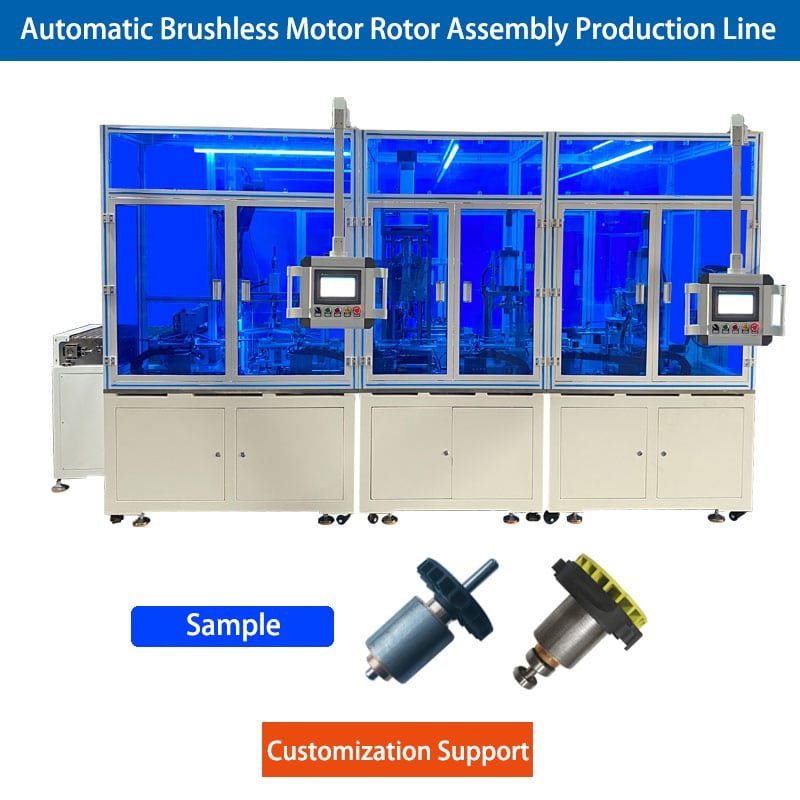

Besides manual methods, the most common method for rotor assembly is the now-popular automated production line. Choosing a production line requires understanding the equipment, evaluating its price, and selecting a reputable manufacturer. So, what are the factors involved in evaluating the price and selecting a manufacturer for a rotor assembly production line? What are its technological advantages? Vacuz will give you a brief introduction below!

I. Price Evaluation: Multiple Factors Driving Cost Fluctuations

The price range for rotor assembly production lines is wide, ranging from $30,000 to one million US dollars, specifically affected by the following factors:

1. Configuration and Scale

Basic Configuration: Includes core components such as the frame, ball screw, guide rails, cylinders, and servo motors, priced at approximately $30,000-$100,000. Suitable for small-scale production or simple process requirements.

High-End Configuration: Integrates a precision robotic arm, multi-axis servo system, intelligent sensors, and real-time monitoring modules, priced at $150,000-$600,000, meeting the needs of high-precision, high-efficiency large-scale production.

2. Brand and Customized Services

Reputable Brands: Leveraging technological expertise and after-sales support, their prices are typically higher than the market average, but they offer long-term maintenance and upgrade support.

Customized Needs: For special processes or non-standard sizes, additional design fees and mold development costs are required, increasing the price by 20%-50%.

3. Market Supply and Demand

When demand exceeds supply: For example, during periods of surge in demand for new energy vehicle motors, production line prices may increase by 10%-20%.

When supply exceeds demand: Through promotional activities or simplified configurations, prices can be reduced to below $30,000.

II. Manufacturer Selection: Comprehensive Assessment of Strength and Suitability

1. Core Assessment Dimensions

Technical Strength: Assess whether the manufacturer possesses key technologies such as multi-axis servo control, precision robotic arm operation, and real-time data feedback to ensure stable production line operation.

Industry Experience: Prioritize manufacturers that have served high-end sectors such as new energy vehicles and aerospace, as they demonstrate stronger process maturity and problem-solving capabilities.

After-sales service: Confirm whether 24-hour response, remote fault diagnosis, and rapid spare parts supply are provided to reduce downtime risks.

Cost-effectiveness: Compare prices from different manufacturers for the same configuration, and calculate long-term benefits considering equipment lifespan, energy consumption, and maintenance costs.

III. Technological Advantages: Automation and Intelligence Drive an Efficiency Revolution

1. Leap in Production Efficiency

Robotic arms and conveyor systems: Enable automatic loading, assembly, inspection, and unloading of parts, increasing single-line capacity by 3-5 times.

24-hour continuous production: Automated processes reduce manual intervention, achieving equipment utilization rates of over 90%, meeting the demands of large-scale orders.

2. Product Quality Assurance

Real-time monitoring and feedback: Collect data such as torque, pressure, and position through sensors, and adjust assembly parameters in real time to ensure product consistency.

Strict testing mechanism: Integrate modules for pressure resistance testing, speed testing, and magnetic flux detection; automatically mark and sort defective products, maintaining a yield rate of over 99%.

3. Flexibility and Scalability

Modular Design: Supports quick tooling and fixture changes and process parameter adjustments, adapting to different rotor models.

Intelligent Reconfiguration Technology: Based on IoT and big data analytics, automatically optimizes production cycle time and material delivery paths, reducing changeover time by over 50%.

4. Safety and Cost Optimization

Safety Protection System: Equipped with overcurrent protection, grounding circuits, and audible and visual alarms, reducing operator injury risk by 80%.

Labor Cost Savings: Reduces the number of workers per line from 10 to 2-3, saving over $100,000 annually in labor costs.

Energy Control: Employs energy-saving motors and intelligent sleep modes, reducing energy consumption by 20%-30% compared to traditional equipment.

What are the price evaluation and manufacturer selection criteria for rotor assembly production lines? What are their technological advantages? Vacuz has provided a brief explanation above; we hope this information is helpful!