When choosing a stator winding machine for a brushless motor for a fan light, we need to consider the structural characteristics of the stator, production efficiency requirements, and product quality standards. The following is a detailed guide from Vacuz to help you make an informed decision.

1. Selection of winding machine types

Flying fork winding machine

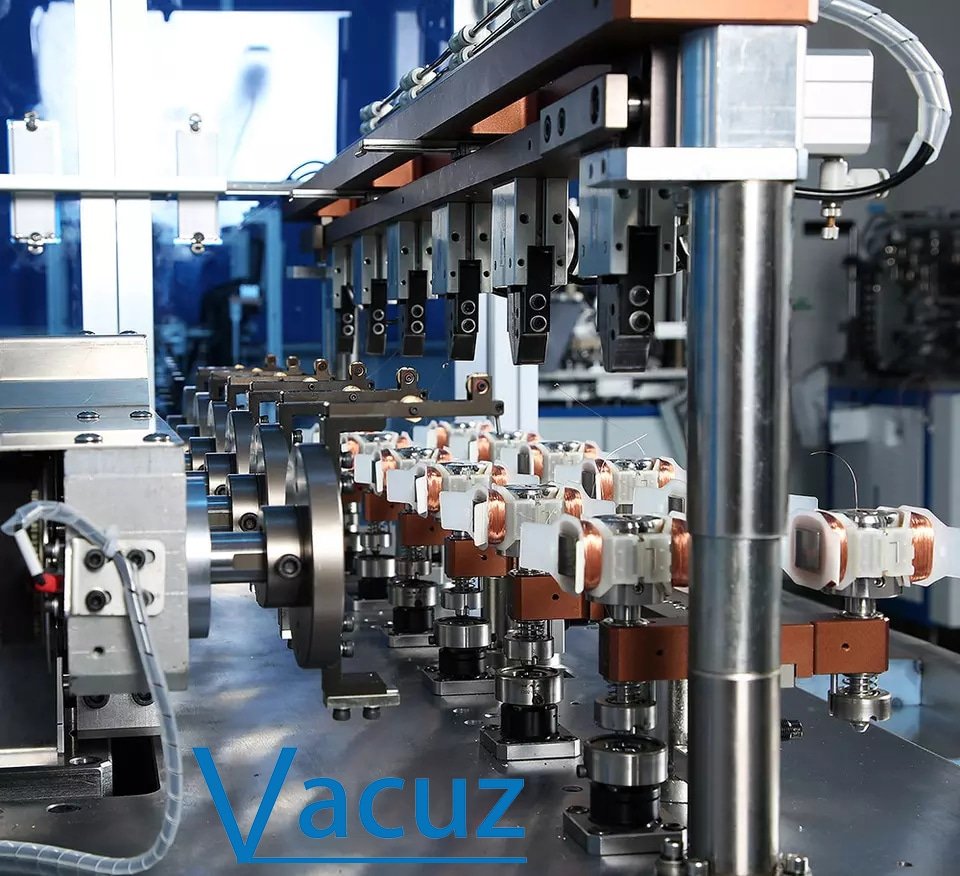

Applicable objects: The stator of a brushless motor for a fan light, with its typical outer rotor structure and outward-opening slots, is generally wound with a flying fork winding machine.

Advantages:

1. High-speed performance: The winding speed of a single station easily exceeds 2800 RPM, and the four-station model doubles the efficiency.

2 Accurate wiring: The powerful combination of servo drive and precision guide rails ensures that the coil arrangement is accurate and the turn error is strictly controlled within ±1%.

3. Multi-wire parallel winding: Supports 2 to 8 wire parallel winding, perfectly adapting to the winding requirements of fan light motors for multi-strand wires.

Needle-type inner winding machine (alternative solution)

Applicable scenarios: This type of winding machine is only considered when the stator adopts a special inner winding structure (such as some micro fans), but such cases are relatively rare.

2. Core configuration and performance standards

1.Drive system: The servo motor ensures stable winding tension with its high accuracy and high responsiveness, effectively avoiding wire damage and wire breakage.

2. Spindle accuracy: The spindle runout is strictly limited to within 0.01mm to ensure winding concentricity and reduce the risk of inter-turn short circuit.

3. Wire nozzle and tension control:

Ceramic wire nozzle: wear-resistant and high temperature resistant, especially suitable for high-speed winding operations with fine wire diameters (such as 0.1mm).

Closed-loop tension system: real-time monitoring and intelligent adjustment of tension to ensure that the coil is tight and unbroken.

4. Wire arrangement mechanism:

Spiral wire arrangement: optimize the coil filling rate, thereby improving the overall efficiency of the motor.

Anti-overlapping design: With the help of advanced algorithms to control the wiring trajectory, the coils can be effectively prevented from crossing and overlapping.

III. Production efficiency and quality control

1. Efficiency improvement:

Multi-station design: The four-station model can wind four stators at the same time, which directly increases the efficiency by four times.

Quick mold change: The mold change time is shortened to less than ten minutes, easily meeting the production needs of multiple varieties.

2. Quality control:

Slot full rate optimization: Through a sophisticated winding algorithm, the slot full rate is improved, and the motor performance is significantly enhanced.

Insulation treatment: Add insulation paper between the wires during winding to effectively prevent inter-turn short circuits.

IV. Equipment stability and recommended models

Equipment stability:

Key components: Select high-reliability accessories such as NSK bearings and THK guide rails to ensure long-term stable operation of the equipment.

Heat dissipation design: Key components such as the spindle and the nozzle use water cooling or air cooling systems to effectively prevent overheating.

Recommended models:

Four-station flying fork winding machine: suitable for large-scale production, high efficiency and stable precision.

Six-station high-speed winding machine: specially designed for ultra-high-speed winding (such as speed ≥3000 RPM), further improving production capacity.

In summary, the selection of fan light brushless motor stator winding machine should focus on the flying fork model, equipped with servo drive, precision wire nozzle and closed-loop tension system, combined with multi-station design and automation function. Such a configuration can not only meet the needs of efficient production, but also ensure the high standard of product quality.

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility”” class=”” id=”"][/fusion_form]