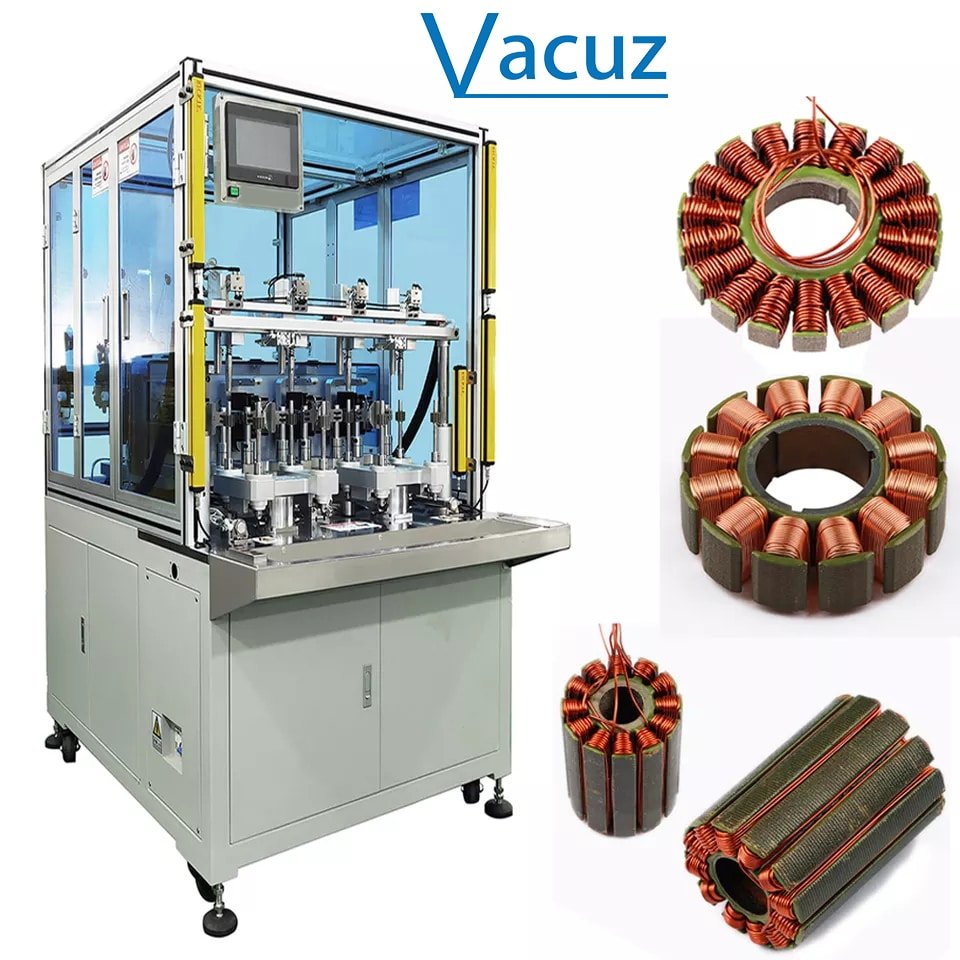

Brushless stator winding machines are critical equipment in motor manufacturing, and their operational stability and accuracy directly impact motor performance and quality. However, in practical applications, winding machines often experience operational instability, often stemming from multiple issues, including the mechanical structure, electrical system, process parameters, and operation and maintenance. To ensure accurate and stable equipment, comprehensive solutions are needed. Vacuz will introduce these solutions!

I. Common Causes of Unstable Operation and Targeted Solutions

1. Mechanical Structure Issues

a. Inadequate Frame Configuration: Lightweight frames are prone to vibration during high-speed operation, affecting winding accuracy. The solution is to use a heavier frame, such as a sheet metal base or stainless steel work surface, with additional reinforcement ribs or high-rigidity materials to improve overall stability.

b. Drive System Wear: Wear on components such as guide rails and lead screws can lead to unsmooth movement. Regular inspection and replacement of worn parts is recommended, and an automatic lubrication system should be implemented to ensure continuous lubrication of drive components.

c. Uneven Ground: High and low elevations in the installation site can cause equipment vibration. The solution is to adjust the equipment height and use a level to calibrate the installation surface to ensure a flat surface.

2. Electrical System Issues

a. Power Supply Fluctuation: Unstable voltage can cause servo motor performance degradation. Install a voltage stabilizer to ensure the power supply voltage is within the equipment’s operating range (e.g., within ±5%).

b. Poor Servo Motor and Driver Quality: Insufficient control accuracy can cause speed fluctuations. Choose a reputable brand servo system and regularly calibrate the motor parameters.

c. Electromagnetic Interference: Control signals are subject to interference during high-frequency operation. The solution is to shield the signal cables, keep them away from strong electromagnetic field sources, or add a filter.

3. Process Parameter Issues

a. Excessive Winding Speed: Exceeding the equipment’s limits can lead to wire breakage or jitter. Set an appropriate upper speed limit based on the wire characteristics (e.g., wire diameter, material) and equipment performance.

b. Improper Tension Control: Excessive tension can easily cause wire breakage, while too little tension can cause loose windings. Use a high-precision tensioner and a closed-loop feedback system for real-time tension adjustment.

c. Uneven Wire Route: Wire accumulation or excessive gaps affect stability. Optimize the wire routing algorithm and use high-precision sensors to monitor wire density and automatically adjust the winding path.

4. Operation and Maintenance Issues

a. Improper Operation: Parameter settings are incorrect or the emergency stop mechanism fails. Establish standardized operating procedures and provide regular operator training.

b. Equipment Aging: Component performance deteriorates due to long-term use. Establish a regular maintenance system to promptly replace aged components.

c. Inadequate Mold Precision: Mold burrs or dimensional deviations can cause wire breakage. Use high-precision molds and regularly inspect mold dimensional tolerances.

II. Comprehensive Approach to Ensuring Equipment Accuracy and Stability

1. Hardware Upgrade

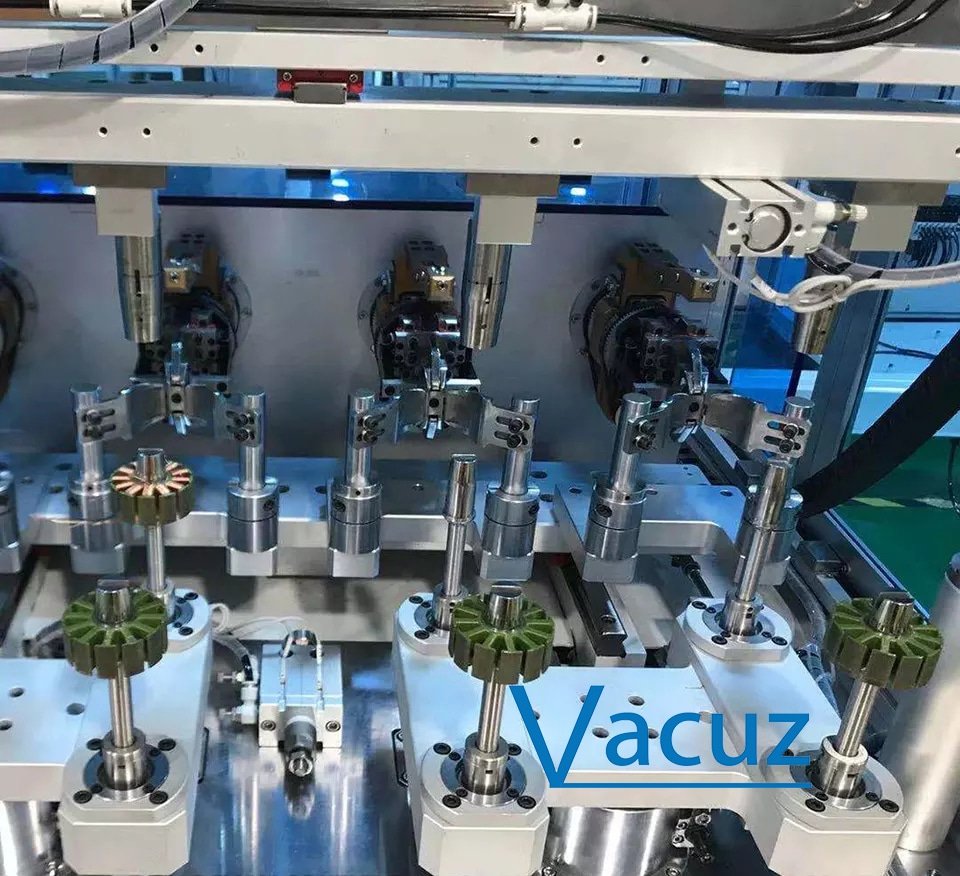

a. Use a high-rigidity mechanical structure, such as a solidly cast frame and linear guides, to reduce deformation during high-speed operation.

b. Use a high-performance servo system, such as a closed-loop control servo motor paired with a high-resolution encoder, to improve trajectory control accuracy. c. Introducing an intelligent tension controller, combining a force sensor and PID algorithm, to achieve dynamic tension compensation.

2. Software Optimization

a. Intelligent Speed Control: Real-time adjustment of winding speed based on wire material and stator slot profile.

b. Automatic Calibration: Automatically detects and corrects parameters upon equipment startup.

c. Data Monitoring and Analysis: Real-time collection of operating data through IoT technology, leveraging big data analysis to optimize process parameters.

3. Environmental Control

a. Temperature and Humidity Management: Installing an intelligent temperature and humidity control system to maintain a stable workshop environment.

b. Dust and Anti-Static: Adopting a dust-free workshop design, equipped with anti-static flooring and ionizing fans, to reduce the impact of dust and static electricity on equipment.

4. Personnel Training and Management

a. Systematic Operation Training: Including theoretical courses and practical training.

b. Safety Awareness Enhancement: Regular safety drills will be conducted to ensure operators are familiar with emergency procedures.

c. Performance Appraisal Mechanism: Equipment stability indicators will be incorporated into operator KPIs to incentivize standardized operation.

In summary, to address the unstable operation of brushless stator winding machines, we need to propose a comprehensive solution addressing multiple aspects, including mechanical structure, electrical systems, process parameters, operation, and maintenance. Furthermore, comprehensive measures such as hardware upgrades, software optimization, environmental control, and personnel training and management will ensure the accuracy and stability of the equipment. This will help improve the quality and efficiency of motor manufacturing and meet market demand for high-quality motors.

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].