To ensure versatility and adaptability to different stator products, brushless motor winding machines require optimization in six core areas: equipment configuration, mold design, multi-station layout, modular structure, intelligent operating system, and automation functions. Furthermore, targeted adjustments must be made to address the parameter differences of various stator products. Below, Vacuz will provide a brief introduction!

I. Equipment Configuration Optimization: The Foundation for Enhanced Versatility

1. High-Precision Servo Control System

Utilizing internationally renowned servo motors and controllers, multi-axis collaborative control is achieved, ensuring accurate management of winding speed, tension, and position. For example, the servo system intelligently adjusts tension to adapt to different wire diameters (0.08-1.3mm) and winding speed requirements, preventing wire breakage or damage.

Upgraded sensors and algorithms achieve a winding accuracy of ±0.01mm, meeting the production requirements of high-precision stator products (such as precision electronic components).

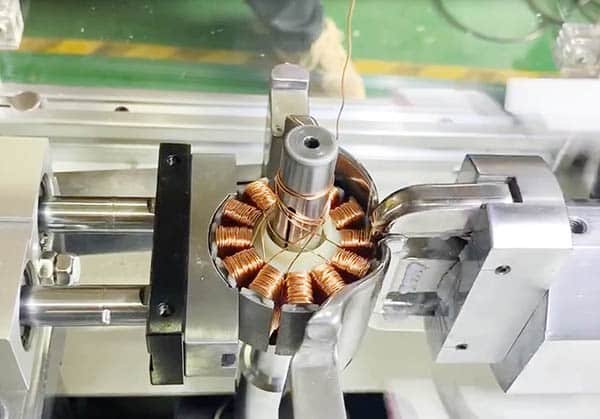

2. Multi-Station Design

Single to six-station configurations are available based on production scale:

Single Station: Suitable for large stators (e.g., high stack thickness, thick wire diameter) or products with complex winding, reducing equipment downtime.

Multi-station (e.g., four-station, six-station): Significantly increases output by processing multiple stators simultaneously (e.g., a 300% increase in winding speed for four-station models), suitable for mass production.

3. Modular Structure

The winding machine components (such as molds, fixtures, and wire laying mechanisms) are designed as replaceable modules. This allows for quick replacement of molds to accommodate different sizes or upgrades to the control system, flexibly responding to market changes. For example, changing the mold allows switching from producing model aircraft motor stators to fan motor stators.

II. Mold Design: Adapting to Diverse Stator Parameters

1. Universal Design

For stators of the same series with the same outer diameter, inner diameter, and wire diameter, if the thickness difference is small (e.g., ≤5mm), mold universality can be achieved by adding shims or auxiliary parts, reducing mold costs.

The mold material is selected from hard alloy or high-speed steel to improve wear resistance and extend service life.

2. Customized Development

For stator parameters exceeding the range (e.g., excessively large outer diameter, excessively high thickness), non-standard equipment customization services are provided to ensure winding accuracy and efficiency. For example, for stators with a thickness of over 200mm, a special process is used to reduce winding oscillation and avoid wire damage.

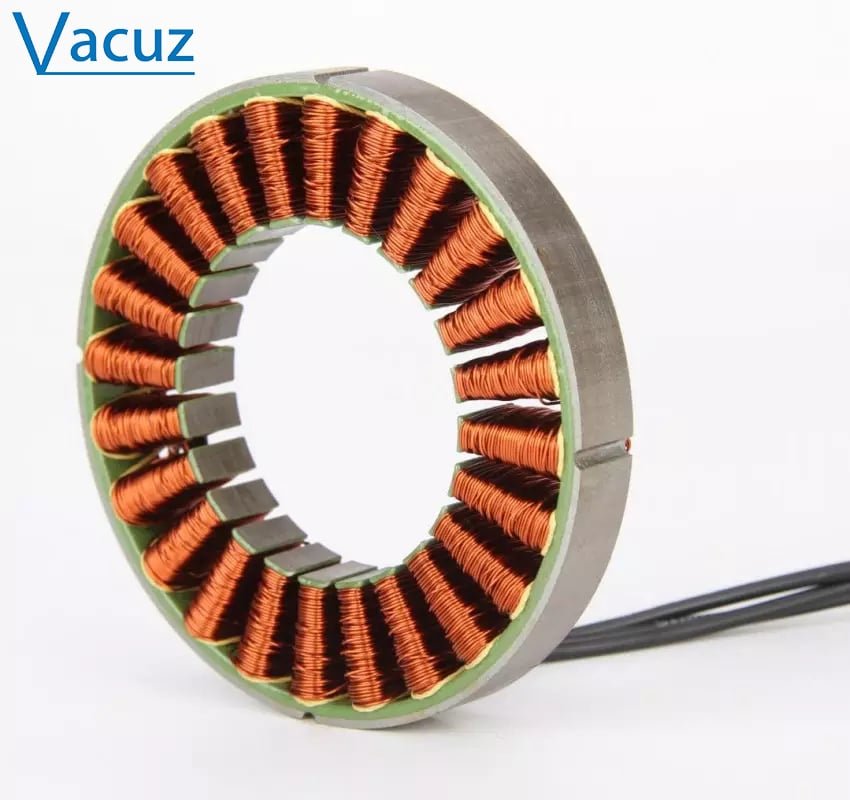

III. Specific Requirements for Different Stator Products

1. Outer Diameter and Inner Diameter

The outer and inner diameters of the stator directly determine the selection of the winding machine model. For example, stators with an outer diameter of Φ70mm-Φ132mm and a stack thickness of 10mm-60mm require equipment suitable for this range; those exceeding this range require different equipment or molds.

2. Stack Thickness (Height)

The greater the stack thickness, the greater the winding oscillation arc, and the higher the risk of wire damage. Ordinary winding machines typically struggle to handle stack thicknesses exceeding 200mm, requiring special processes (such as vibration damping devices, low-speed winding) or customized equipment.

3. Wire Diameter and Multi-Wire Winding

Wire Diameter: The thicker the wire diameter, the higher the requirements for equipment tension control. For example, 0.2-0.3mm wire diameter can be wound with 30 wires simultaneously; it is necessary to ensure that the equipment can stably handle multi-wire tension to avoid wire breakage.

Slot Spacing: Adjust the slot spacing according to the wire diameter. When the wire diameter is thick or multiple wires are wound simultaneously, the slot spacing needs to be increased to prevent scratching and damage to the wires. 4. Coil Turns and Winding Speed

High-turn-count stators (such as fan series) require high-speed winding machines (no-load speed up to 1000 RPM) to improve efficiency and ensure neat winding, avoiding short circuits between turns.

5. Slot Orientation

Inner-wound stators: Slots facing inward, requiring a needle-type inner winding machine. Winding is achieved through the up-and-down movement of the needle bar and the left-and-right movement of the die. Suitable for motors in water pumps, household appliances, etc.

Outer-wound stators: Slots facing outward, using a flying fork winding machine. Winding is achieved through the interaction of the grinding head, die, stator rod, and guard plate. Suitable for motors in model aircraft, fans, etc.

IV. Intelligent Operating System and Automation Functions: Improving Production Efficiency

1. Intuitive Programming Interface

Provides graphical programming and support for various programming languages, simplifying parameter setting processes and lowering the operational threshold. For example, winding parameters (speed, tension, number of turns) can be monitored in real time via a touchscreen, allowing for quick adjustments to the production plan.

2. Automation Integration

Integrates automatic loading and unloading, line changing, and inspection functions, reducing manual intervention and improving production safety and consistency. For example, it automatically detects coil turn error (within ±1 turn) and wiring flatness (≤0.5mm) to ensure product quality.

How can the versatility of brushless motor winding machines be balanced? What are the requirements for different stator products? Vacuz has provided a simple explanation above, and we hope this information will be helpful!