Automatic CNC winding machine for which fields

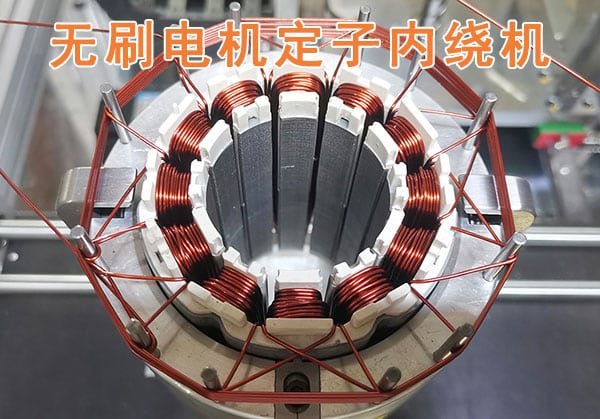

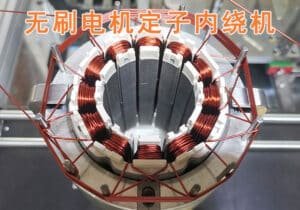

Automatic winding machine is easy to operate and easy to use, but automatic winding machine, loop winding machine, is not available in all industries, which apply the performance of automatic winding machine with electronic toy industry coils, coils for electronic watches, electronic playing most suitable gift coils, electronic lock induction coils, cell phone vibration motor coils, induction coils for animal ear tags, earphones and speakers with various voice coils, card reader coils, ID/IC Automatic coin device coils, coils for video cameras, digital camera zoom coils, laser head coils, special magnetic head coils, wireless mouse and mouse pad solenoid coils, automatic coin device coils, coils for hearing aids, time and attendance coils, coils for solar turntables, solar swing coils, coin detector coils and no flat brush motor coils.

What is the difference between several fully automatic winding machine speed modes?

Since fully automatic magnetic coil winding machine, no manual operation is required, so the requirements for professional operators are higher in order to adapt to the process. Coil winding machine are equipped with automatic spindle speed control function, due to the type of winding machine to distinguish the treatment of its configuration is different, we are all more familiar with the type of spindle motor for the AC motor, DC motor, these three servo-driven motor, speed governor use the way these motors have their own characteristics, the following fully automatic winding machine speed mode.

A, fully automatic stranding machine AC motor speed mode.

These motors themselves are no speed control function, it needs to be installed by the electromagnetic control device or drive to achieve speed control function, we compare the winding device inverter is a common way to winding through the device with speed control frequency motor function of the control system, this method also has a role in the energy-saving part.

Second, DC motor speed control automatic winding machine mode.

DC power needs to be converted to DC power to drive the motor operation, so DC motors are equipped with brushless DC speed control board or control motor drive to drive, because the motor in a small number of large winding equipment smaller applications.

Third, the automatic winding machine servo-driven motor speed method.

It is a precision moving parts for high precision winding equipment, as well as supporting the use of special drives to achieve closed-loop operation control, this type of engine is characterized by constant torque, closed-loop operation, designed to meet the processing requirements of precision coils.

WhatsApp/ウィチャット+86 13075286997

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].