Transformer as the power industry transmission and transformation of basic equipment, widely used in power plants, converter stations, substations and user side, in the power industry occupies a very important position, and its demand is also accumulating, the market outlook is very broad. This has put forward higher requirements for the production power of our transformers, a companion with the global energy crisis, the production of more energy-efficient transformers is also imperative. It is in this context, China’s transformer production standards are also repeatedly improved, the requirements of the function of the target is also increasingly serious. There are two directions for the future development of transformers: one is ultra-high voltage and large capacity, and the other is high efficiency, intelligence, small size and low noise. The quality and economic and technical functions of transformers are influenced by the structural design, but also depend largely on the technical level of production technology and production equipment. In order to meet the increasingly serious requirements for transformer quality and functional goals, we need to improve the technical level of transformer winding machine, so that it can produce the production of transformers to meet the needs of national power development.

自動巻取機

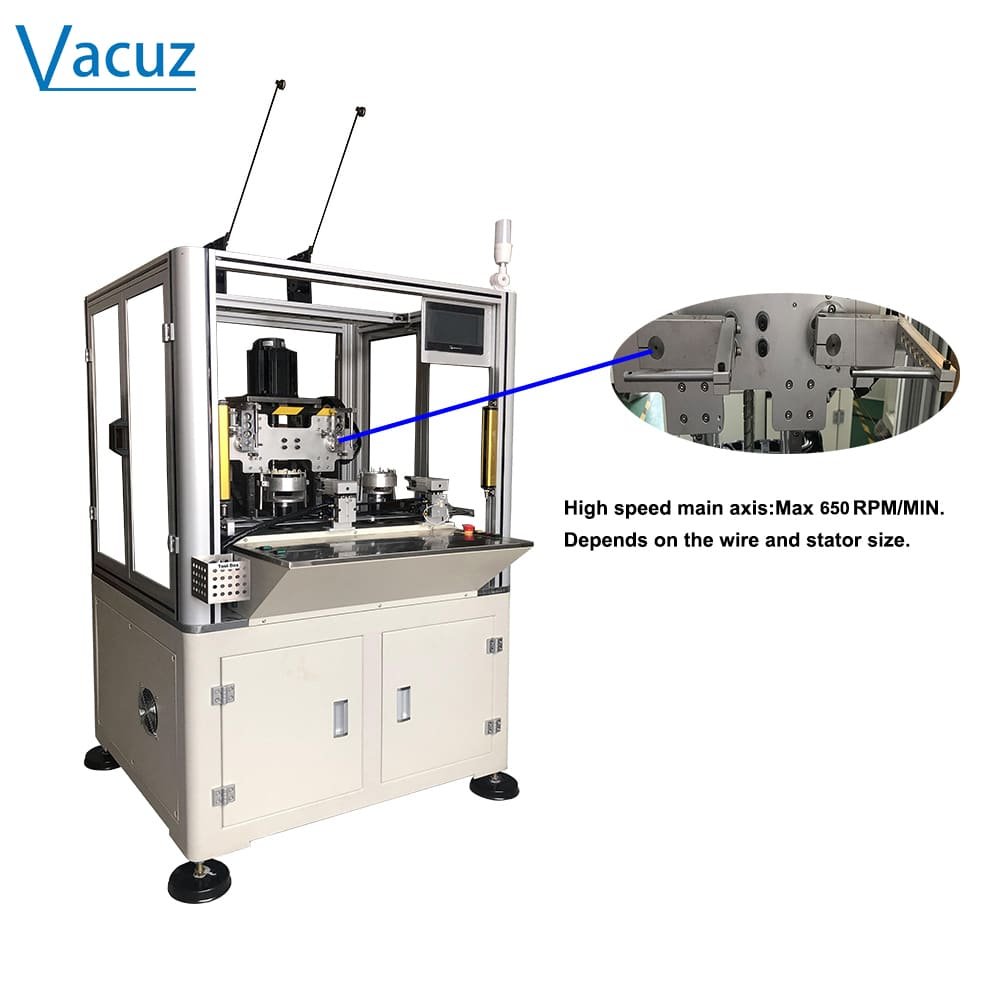

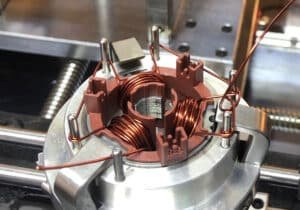

Transformer is generally composed of core, coil, shell and necessary insulation materials. Transformer coils are generally divided into high-voltage coils and low-voltage coils. High-voltage coils are generally wound with round insulated wires, while low-voltage coils are generally wound with flat insulated wires or foil materials. Transformer coil winding is the central process of transformer production, the function of the transformer has a great impact. It not only directly resolves the transformer size, loss and weight of the primary economic and technical objectives, but also directly affects the mechanical function of the transformer, insulation and heat-resistant function of the primary quality objectives. Traditional transformer coil winding is relying on manpower to wind the insulated wire to the workpiece in accordance with the production process requirements, and by the operator to count the number of resistance. With the traditional winding method, not only is the winding power low, but the quality of the coils is also poor. Nowadays, automatic winding machines are widely used for transformer coil winding, which can significantly improve production power and line up accuracy. Among the automatic winding machines, there are vertical winding machines for large transformers, as well as horizontal winding machines and foil winding machines for lower voltage and smaller capacity transformers.

WhatsApp/ウィチャット+86 13075286997

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].