The technical requirements of the stranding machine of the coil winding machine!

Stranding machine is also called high speed stranding machine, wire bundling machine, nimble wire machine.

Stranding machine is widely used in all kinds of soft / hard conductors (copper wire, enameled wire, tinned wire, copper-clad steel, copper-clad aluminum, etc.) and electronic wire stranding, such as: power lines, telephone lines, audio lines, video lines, car lines, network lines, etc.. Make multiple single conductors twisted into one, to reach the wire process to.

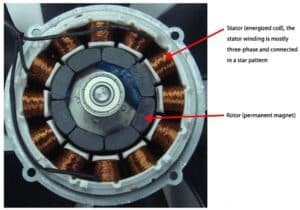

Coil winding machine

Technical features.

1, stranding machine spindle Z high speed of 3000rpm.

2, active tension control: stranding, the collection of wire from the bottom of the disk to receive the full disk when the collection of tension needs to increase, the machine can take the initiative to track and adjust the collection of tension; so that the whole disk collection of tension evenly together, together with the machine can also adjust the tension without stopping.

3, the host is oil smooth, natural circulation cooling, useful to extend the service life of the spindle bearing.

The new structure is used for the wire crossing system, the wire is directly crossed from the spindle guide wheel to the bow belt, which eliminates the scratching and jumping phenomenon caused by the failure of the corner guide wheel on the aluminum disk.

4、The machine is equipped with three tightening devices to ensure the roundness of the conductor after stranding and to reduce the loss of insulation materials.

5、The whole machine uses synchronous belt drive, no smooth point in the machine, adhere to the machine clean, stranded wire without oil, to adapt to all kinds of appearance cleanliness requirements of the conductor stranded wire species.

6、Adjusting the stranding distance only requires replacing one draw wheel, and adjusting the stranding direction only requires wrenching the reversing lever, which is simple and easy to operate, and then decreases the error rate and work intensity of the operator. The bearings of the whole machine are made of famous Japanese brands, and the bow belt is made of new materials with good flexibility to avoid jumping caused by vibration when running at high speed, and the frequency converter, PLC, magnetic powder clutch, electromagnetic brake and hydraulic jack are all imported famous brands to reduce the failure rate and maintenance cost.

WhatsApp/ウィチャット+86 13075286997

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].