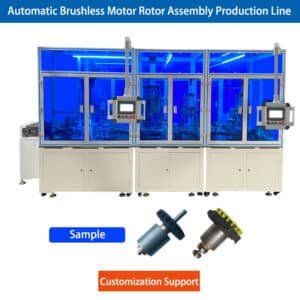

技術の急速な発展に伴い、ブラシレスモーターの生産は、効率を向上させるだけでなく、大幅にモータの品質を向上させるだけでなく、モータの生産ラインと、自動組立ラインから切り離されていない、その後、ブラシレスモーターの自動組立ラインの設計プロセスは何ですか?

1.モーター自動組立ラインに対する顧客のニーズ(製品の品質、効率、その他の要件を含む)を理解し、プロジェクト全体の計画を決定する。

2.製品の生産工程、製品のサイズ、原材料の受入方法など。

3.プログラム、全体生産図、各アクション、設備パラメーターなどを決定する。

4.プログラムを検討し、各パーツの実現可能性、コスト、生産効率、構造を評価する。

5.計画を決定し、それを顧客に伝え、顧客は生産準備が整う前に計画に従って同意する。

6.機構、機械組立図、部品図、選択された実行部品、電気制御付属品などをセットアップするエンジニアを手配する。

7.メカニズムの各部分はシンプルであるべきであり、デバッグが容易であるべきであり、メンテナンスが容易であるべきであり、各部分は可能な限りシンプルであるべきであり、加工が容易であるべきである。

8.スペアパーツの準備ができたら、組み立てクランパーが組み立て、組み立てた後、機械をデバッグし、プルーフィングを終え、サンプルをテストし、サンプルを送り、顧客が決定する。

9.顧客決定後、モーター生産ラインは完成し、出荷のために梱包される。

上記はブラシレスモーターの自動組立ラインの設計工程と必要条件であるが、実際には、これは予備的な説明に過ぎず、具体的な工程は修正などを含め、より複雑である。

WhatsApp/ウィチャット+86 13075286997

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].