With the rapid development of the motor industry, the application of brushless motor motors is becoming more and more widespread, and the supply and demand is also increasing. How to reduce the labor intensity of employees, reduce the pressure on factories and improve production efficiency is a problem that many motor manufacturers urgently need to solve.

In order to solve the problem of production efficiency and labor, many manufacturers began to invest in brushless motor automation production line, compared to manual or semi-automatic production mode, significantly improve production efficiency and reduce labor for enterprises.

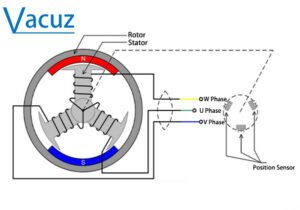

Brushless motor automation production line can realize automatic assembly, automatic testing, automatic detection, automatic dispensing, automatic labeling, packaging, coating, handling, etc. All positions coordinate and cooperate to quickly complete the assembly of brushless motors and increase the capacity benefit.

Brushless motor automatic production line can accurately detect the good or bad of motor products, through machine vision instead of manual inspection, 360 degree appearance inspection of the product, accurately determine whether the wiring is reasonable, the whole process is less than one second, greatly improving the efficiency of detection, with fast, high accuracy, high efficiency, etc. If there are any defective products, they will be selected for improvement to ensure the quality of factory products.

With the brushless motor automation line, the production process from feeding, winding, fastening, stator and rotor assembly, etc., are all done by the automation equipment, and the personnel only need to supervise the production and ensure good production.

On the other hand, the automatic motor production line promotes the construction of “informationization” and realizes intelligent production, which also drives the improvement of factory staff quality and the overall upgrade of intelligent equipment and products in the upstream and downstream industry chain.

It is worth mentioning that the motor automation line can be customized as needed and the information system created can be used for automatic product quality traceability. By monitoring and managing each production step, responsibility is placed on the person and product quality is strictly controlled. Production progress can be mastered in real time, which is efficient and convenient.

WhatsApp/ウィチャット+86 13075286997

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].