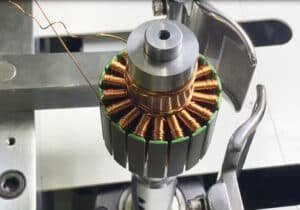

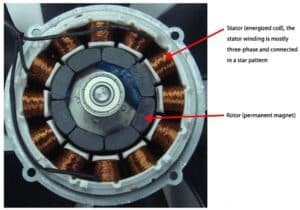

Brushless motor in the production process, winding is a relatively important part of the core part of the motor, the stator coil winding, the need to use professional equipment, especially for large quantities of products, of course, manual can also be, but there are still quite a lot of problems. So stator coil winding manual semi-automatic and automatic winding machine what is the difference?

First, manual semi-automatic winding, which is more traditional stator coil winding method, there are still many small manufacturers so winding, if the batch is not large, winding the number of turns, or barely.

Advantages: small batch manual winding, low cost, fast delivery, a few people or yourself can be completed, will not delay customer orders.

Disadvantages: not suitable for medium and large quantities, winding complex, many turns, high requirements of the stator winding products, if the customer demand tens of thousands of hundreds of thousands of products, need to be done within a few days, manual that is impossible, even if you can that also need to hire many people, not cost-effective; for winding complex, many turns of products, manual is easy to remember the wrong number of turns, winding process negligence and other circumstances, resulting in product consistency is not stable, the number of turns is wrong, which will produce many defective products, directly affecting the quality.

Second, most medium and large manufacturers use professional equipment, automatic winding machine equipment or production line, for large quantities, fine lines, turns, winding complex products, just enter the corresponding winding program, you can quickly wind out in accordance with the requirements.

Advantages: For products with different outside diameter and wire diameter, it can be divided into 2-station, 4-station and 6-station equipment, and the speed of external winding can reach more than 2500R.P.M, and the speed of internal winding can reach 1000R.P.M. The production efficiency is high and fast, which is incomparable with manual semi-automatic.

Disadvantages: the main equipment upfront investment cost is a little larger, the machine and equipment should be debugged, the product should be tested and qualified before production, so as not to cause batch accidents.

These are the main differences between manual semi-automatic and automatic stator coil winding machine, each has its own advantages and disadvantages, according to their own situation, you can choose the right winding method to ensure greater production profits.

WhatsApp/ウィチャット+86 13075286997

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].