Winding efficiency varies from machine to machine, from manufacturer to manufacturer, and from machine to machine with different configurations. Vacuz has summarized its optimization solutions for improving the operational efficiency of automatic motor stator winding machines, covering six key aspects and their implementation results. We hope this helps!

I. Equipment Hardware Optimization: Improving Basic Performance

1. Core Component Upgrade

Motor and Drive System: Utilizes a high-power-density servo motor (≥3000 RPM) coupled with a torque motor for direct drive, achieving spindle speeds exceeding 5000 RPM and eliminating mechanical transmission errors.

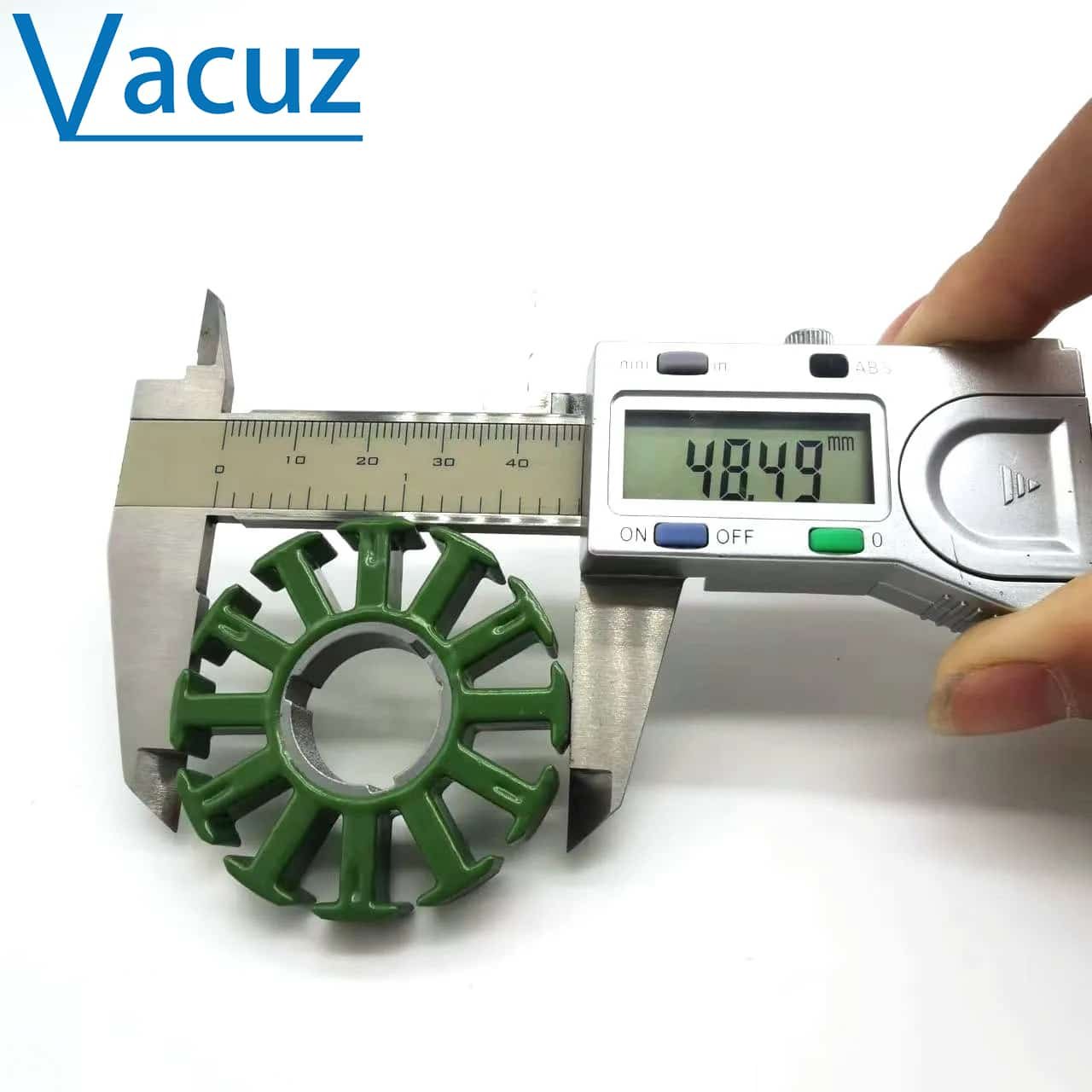

Drive Components: A ball screw + linear guide combination offers a positioning error of ±0.01mm. With optimized dynamic response, acceleration reaches 1.5G, enabling high-speed starts and stops.

Nozzles and Dies: A ceramic/tungsten carbide nozzle with a pneumatic fine-tuning mechanism compensates for wire diameter variations in real time; wear-resistant dies reduce winding resistance.

2. Workstation Expansion and Modular Design

Multi-station (dual/quadruple) configuration allows for flexible modularization, reducing workstation switching time by 50% and increasing equipment utilization by 30%.

II. Control Algorithm Innovation: Intelligent Collaboration

1. Path Planning and Speed Control

Spiral Trajectory: Generates a smooth path based on the NURBS algorithm, reducing wire stress.

Speed Look-Ahead: Preemptive deceleration at path corners, and S-shaped acceleration and deceleration curves reduce mechanical shock.

Vibration Suppression: A notch filter suppresses resonance and improves speed stability.

2. Tension and Speed Collaboration

Closed-loop tension control (0.5-5N for copper wire, 0.3-3N for aluminum wire) is combined with a speed-tension mapping table for adaptive adjustment.

III. Process Parameter Optimization: Adapting to Diverse Needs

1. Parameter Database and Adaptive Optimization

A process database is established to support rapid parameter matching; a reinforcement learning algorithm automatically optimizes parameters based on real-time data.

2. Dynamic Slot Fill Rate Calculation

Closed-loop feedback adjusts wire spacing, improving slot fill rate uniformity by 20%.

IV. Workstation Design and Automated Operation

1. Multi-station Collaborative Production

Simultaneous processing of multiple stators reduces winding cycle time by 40% and improves efficiency by 30%.

2. Automation Function Integration

Automatic corner wrapping, loading and unloading, and wire trimming reduce manual intervention and reduce idle time by 15%.

V. Real-time Monitoring and Fault Prevention

1. Machine Vision and Sensors

High-speed cameras + AI algorithms detect wire defects (≥99.5% accuracy); multi-source sensors predict faults (such as tensioner wear).

2. Thermal Error Compensation

Infrared thermal imaging corrects position commands in real time to compensate for thermal deformation errors.

VI. Personnel Operation and Maintenance Optimization

1. Standardized Operating Procedures

Develop an operating manual to standardize parameter settings, mold changes, and other procedures to reduce human error.

2. Regular Maintenance and Training

Regularly lubricate the spindle/bearings and replace worn parts; operator training enhances skills and safety awareness.

3. Implementation Results and Value

Efficiency Improvement: Winding speed increased by 30%, idle time decreased by 15%, and single stator cycle decreased by 40%.

Quality Improvement: Wire breakage rate ≤ 0.1%, slot fill uniformity increased by 20%, and noise/vibration decreased by 10%-15%.

Cost Savings: Wire material savings of 5%-10%, die change frequency decreased by 30%, and maintenance costs decreased by 20%.

Equipment Lifespan: Thermal compensation and regular maintenance extend equipment lifespan by 20%-30%.

Summary:

Through comprehensive optimization of hardware upgrades, intelligent algorithms, process adaptation, automated workstations, real-time monitoring, and personnel training, motor stator winding machines have achieved significant breakthroughs in efficiency, quality, and cost, providing a highly competitive solution for large-scale production.

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].