In order to ensure the proper operation of automatic winding machine, daily inspection and correct operation are indispensable and important steps. First of all, the first winding machine manufacturer should create an equipment manual for daily record keeping and inspection. Read the operation and problems of automatic coil winding machine.

When starting work, we must carefully inspect the table, cable conduit and all major sliding surfaces. If there are obstacles, tools, impurities, etc., they must be cleaned, wiped down, oiled, and the equipment moving mechanism must be carefully inspected for new pulls or studies. If there is any injury if the equipment should be notified to see if it is analyzed as being caused by a malfunction and a record made, check that the peace protection, power supply, restraints, etc. should be intact, check that the distribution box should be closed and that the electrical grounding is good. Check that the attachments to the equipment are in good condition.

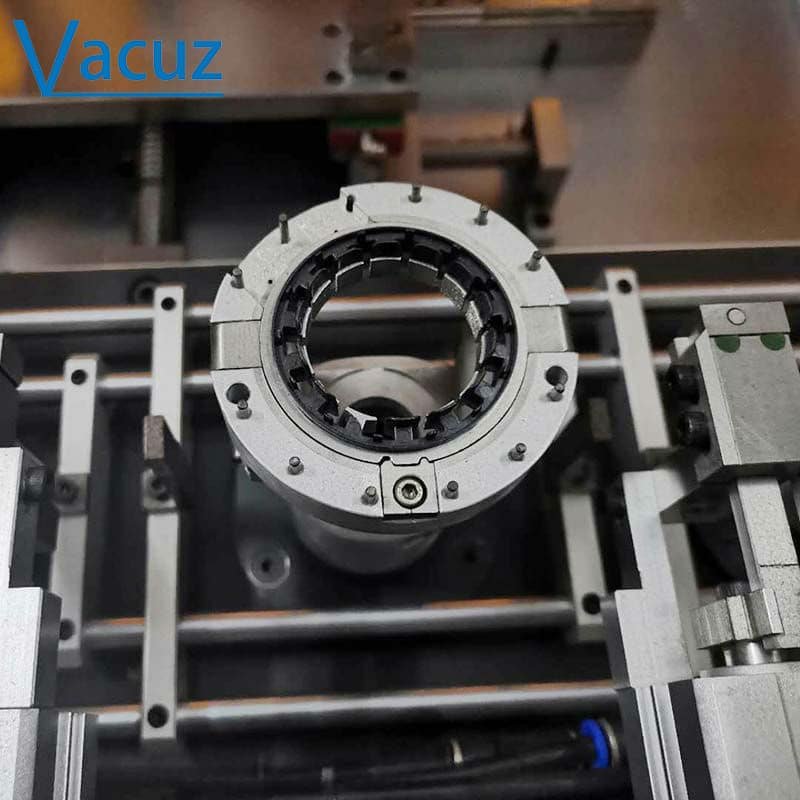

Rear wheels, felt clips, payoff frames, ceramic parts, etc. should be complete and correctly installed, and idling running tests should be conducted to determine whether the operation is stable and whether there is any abnormal noise. Although the above work is troublesome, it is effective in determining whether the equipment is in good condition and preventing malfunctions.

If there is no abnormality after checking, the equipment can be started normally for winding work. During operation, the operator also needs to strictly follow the rules of use. There are many unintentional operations that can damage the equipment to varying degrees. During use, care should be taken not to do anything unrelated to work. When leaving the equipment, stop it and turn off the power and air source. It should be wound according to the process regulations. Do not increase the wire diameter, number of turns and winding speed arbitrarily.

Do not allow the automatic winding machine to be used for over standard, overload and overweight. Spools and dies should be properly clamped. Do not allow the use of long shanks to increase the torque for tightening the dies. Mechanical shifting of spindle and cable mechanism and molds is not allowed. Clamping, adjustments, etc. should be made after stopping the machine. Protective devices are provided to ensure the safety of the operator in case of abnormal equipment conditions. Removal of safety protection devices on the equipment is not allowed. Special configurations for automatic winders. Do not allow tools, workpieces, and other debris to be placed directly in the diameter of wire screws and winding wires. Pay close attention to the operation. If you notice abnormalities such as malfunctions, vibration, heat, creeping, noise, odor and bruises, stop the machine immediately. After troubleshooting, you may continue working.

WhatsApp/ウィチャット+86 13075286997

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].