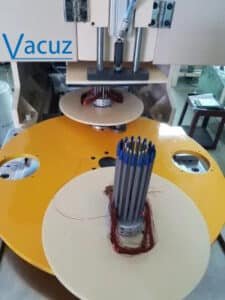

Usually, a multi-head linkage design is used. Most domestic manufacturers refer to the design of imported models from Taiwan and other places. Programmable controllers are used as the control core of the equipment, and robots, pneumatic control elements and actuating accessories are used to complete the automatic threading, automatic foot wrapping, automatic thread cutting, automatic loading and unloading of the skeleton, etc. The production efficiency of this model is extremely high and greatly reduces the dependence on labor. The operator can take care of several such machines at the same time and compare the quality of production. Stable and ideal for machining applications with high production requirements. However, this model integrates a number of new technologies such as CNC, pneumatic and optical controls, and because the functional requirements dictate the use of a large number of non-standard and customized parts for the equipment’s components, the maintenance process can be complicated if it is a failure. It is advanced. High output still attracts customers. Porter Automation Network specializes in all kinds of automatic coil winding machine and so on, strong professional product quality assurance for all kinds of automation products in China and Southeast Asia.

Introduce the use and characteristics of automatic winding machine: this equipment is a new type of winding equipment developed successfully this year. Mainly used for electric heating alloy enterprises resistance wire / band, heating frame curve molding, instead of the original manual winding, greatly improve production efficiency, save production costs, improve product / product competitiveness, greatly improve your electric heating wire sales.

Performance and specifications: specifications can be customized according to the requirements of user units; (maximum custom flat wire specifications: width 30mm; thickness 3mm maximum adjustable width of 350mm; replacement of molds can be used for round wire curve forming and change the shape of the curve).

WhatsApp/ウィチャット+86 13075286997

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].