Brushless motor stator winding is a relatively troublesome process for the manual, winding and lining up is certainly difficult, mainly because the line is not tight, bloated, can not achieve precision lining, there is low production efficiency, winding a sample can be, mass production is more difficult.

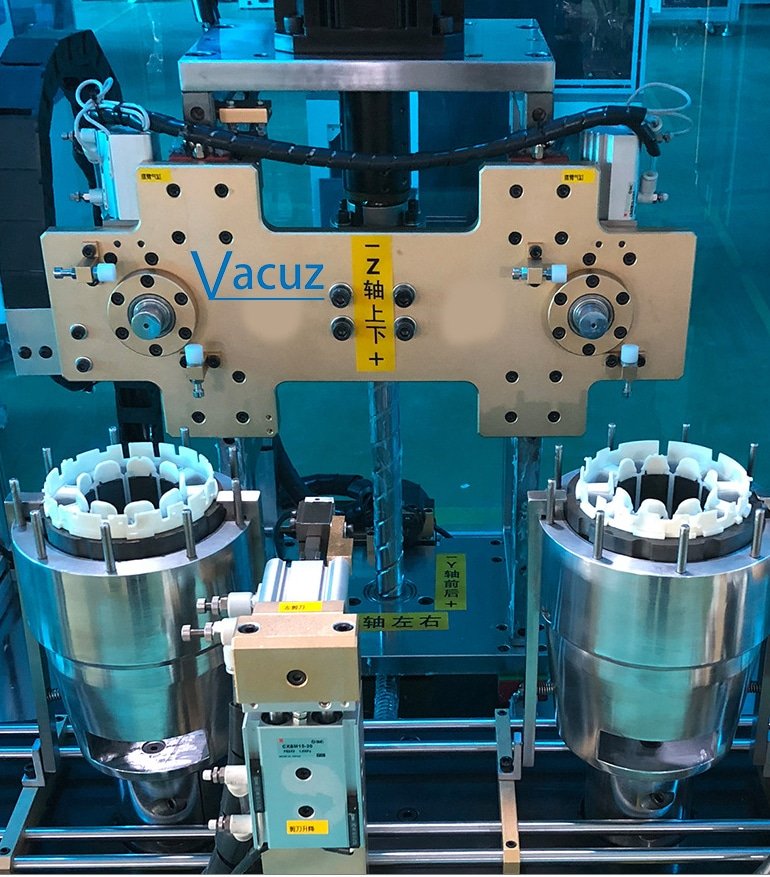

In fact, now the stator mass production of winding do not rely on manual, mainly using professional winding equipment, such as external winding stator commonly used flying fork winding machine, you can use single-station, double-station, four-station equipment; internal winding stator often use needle winding machine, you can use double-station, four-station, six-station equipment, can achieve mass production, high production efficiency, reduce manual labor intensity, while winding lineup is also more precise, the effect Better.

Multi-line winding is more than one enameled wire together and winding, external winding machine and internal winding machine can be achieved, but in fact, there are still certain conditions, the wire diameter can not be too thick, flying fork winding machine general 0.3mm wire diameter can be about 30 and winding, 0.5mm or so, only a few and winding, internal winding machine is relatively and winding number less, mainly with the wire diameter has a certain relationship.

Winding coarse wire and fine wire also has a big difference, coarse wire wire diameter is generally about 1.0mm, or even more than 1.5mm, winding easy to hurt the line, generally used for power tools, garden tools stator products, winding, we must pay attention to the injury problem, debug the machine, do a good brine test. Fine line wire diameter is generally about 0.1mm, winding is mainly afraid of breaking the line, generally used in small pumps, high-speed wind cylinder, electric toothbrush, rotary change, cooling fan and other motor stator, winding, the speed must not be too fast to avoid breaking the line injury.

Is it difficult to line up the stator winding? How to achieve multi-wire winding? What is the difference between thick and thin wire winding? The above has been a simple explanation, I hope these tips can help you!

WhatsApp/ウィチャット+86 13075286997

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].