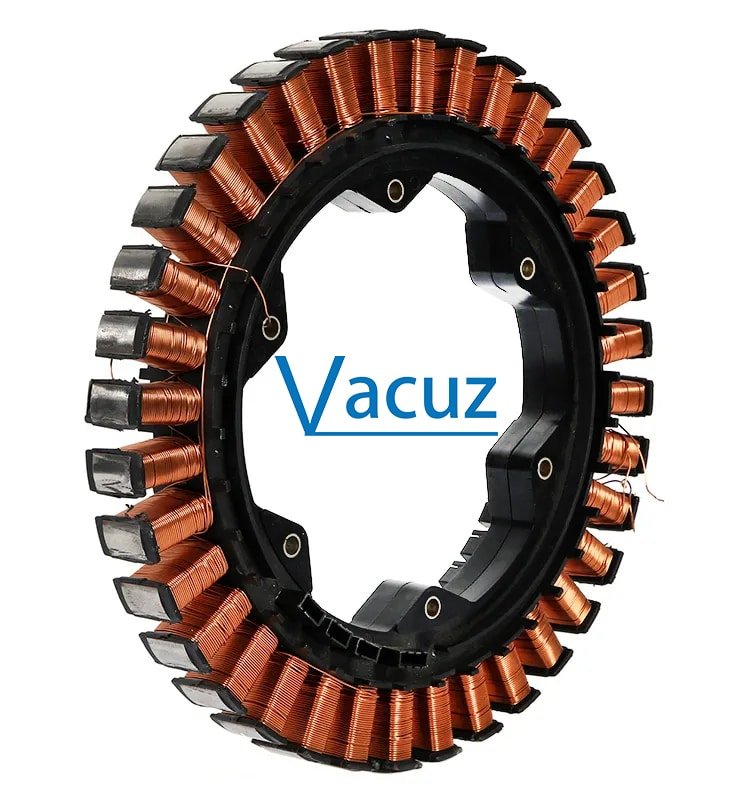

Stator winding machine to achieve the goal of accurate number of turns and neat rows, it really needs to be in a number of aspects of the comprehensive consideration and optimization, if not to meet, it will not achieve the desired effect of winding, then how to achieve accurate number of turns and neat rows? What conditions should be met, Vacuz give you an introduction to it!

In the pursuit of stator winding machine turns accurate and neat process, we need to be from the hardware configuration, software and parameter settings, debugging and maintenance, as well as other key factors and other dimensions of in-depth discussion and practice. The following is a detailed analysis of these aspects:

First, the hardware configuration: lay a solid foundation

1. High-precision tensioner: the configuration of brand servo tensioner, is to ensure that the wire tension control is accurate key. Servo tensioner with its excellent stability and accuracy, can effectively avoid the improper setting of tension and lead to broken or untidy row of problems. By accurately regulating the amount of tension, we can realize accurate control of the number of turns while safeguarding the integrity of the wire.

2. Precision mold and positioning device: The design and processing accuracy of the mold is directly related to the winding effect. Adopting high-precision molds and ensuring that their surfaces are free of bumps and burrs can effectively prevent the occurrence of wire scraping phenomenon. At the same time, the positioning device of the mold needs to be closely coordinated with the line device to achieve accurate guidance of the wire in the winding process, to ensure that the line is neat and orderly.

3.PLC servo drive controller: as the “brain” of the winding machine, PLC servo drive controller selection is critical. The use of precision controllers can significantly improve the stability and accuracy of the winding process. Low-precision controllers are often difficult to handle the complexity of the winding task, while high-precision controllers can ensure that each step of the winding process in accordance with the predetermined procedures for accurate implementation, thus achieving accurate control of the number of turns and rows of neat and tidy.

Second, the software and parameter settings: optimize the control strategy

1. Reasonable parameter settings: For different stator sizes and wire specifications, we need to ensure that the winding machine is in proper working condition through refined parameter settings. This includes, but is not limited to, the adjustment of winding speed, tension size, number of turns and other key parameters. Reasonable parameter settings can give full play to the performance advantages of the winding machine, reduce the inaccurate number of turns and rows of untidy problems caused by improper parameters.

2. Programming control: the introduction of programming control technology can further enhance the degree of automation and winding accuracy of the winding machine. By presetting the winding program, we can ensure that each step of the winding process is carried out in accordance with the established procedures, thus reducing the errors caused by human factors. Programming control also has the characteristics of high flexibility, according to the actual needs of rapid adjustment and optimization.

Third, debugging and maintenance: to ensure stable operation

1. Debugging process: before the winding machine is officially put into production, a comprehensive debugging work is essential. In the commissioning process, we need to gradually adjust the parameters and device configuration, until a good winding effect. Commissioning personnel need to have a wealth of professional knowledge and practical experience to cope with the commissioning process may appear in a variety of problems and challenges.

2. Regular maintenance: In order to ensure the long-term stable operation of the winding machine and the continuous improvement of the winding quality, we need to maintain and repair the winding machine on a regular basis. This includes checking the wear and tear of various devices and spare parts, replacing damaged parts in time, cleaning and maintaining the machine. Through regular maintenance, we can find and solve potential problems in a timely manner, to extend the service life of the winding machine and ensure its stable performance.

Fourth, the other key factors: the details can not be ignored

1. Wire quality: wire as the basic material in the winding process, its quality is directly related to the winding effect. Selection of good quality, consistent specifications of the wire can effectively reduce the number of turns due to problems caused by the wire itself is inaccurate and untidy phenomenon.

2. Environmental control: the winding process also needs to pay attention to the environmental temperature, humidity and other environmental factors on the winding effect. By controlling the scope of change of these factors, we can provide a more stable working environment for the winding machine, so as to ensure the stable improvement of the winding quality.

How can the stator winding machine achieve the accurate number of turns and neat rows? To meet what conditions?V above has done a simple narrative, want these tips can help you!

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].