Motor stator internal winding machines are typically used to wind inner stator products. They employ a pin-type winding method, moving up and down to quickly wind enameled wire into the stator slots. To improve efficiency, four-station or six-station machines are often used. So, what are the precision requirements for multi-station internal winding machines for motor stators? How can winding quality be improved? Vacuz will explain!

I. Precision Requirements: Multi-dimensional Indicators to Establish Quality Benchmarks

1. Core Parameter Precision

Coil Turns Error: Must be strictly controlled within ±1 turn to avoid motor performance instability due to turns deviation.

Wire Diameter Deviation: Requires a wire diameter error ≤ ±0.01mm to ensure the wire’s compatibility with the stator slot shape and prevent damage due to excessively thick wire or breakage due to excessively thin wire.

Wire Arrangement Neatness: Wires must be arranged tightly without crossing, with an interlayer gap error ≤ ±0.05mm to reduce coil resistance fluctuations and electromagnetic interference.

2. Stator Adaptability Accuracy

Slot Parameter Adaptation: The slot width needs to be dynamically adjusted according to the wire diameter and the number of parallel strands.

Layer Thickness Control Accuracy: The stator layer thickness error ≤ ±0.1mm, avoiding changes in winding curvature due to layer thickness deviation, which could lead to wire damage or uneven wire arrangement.

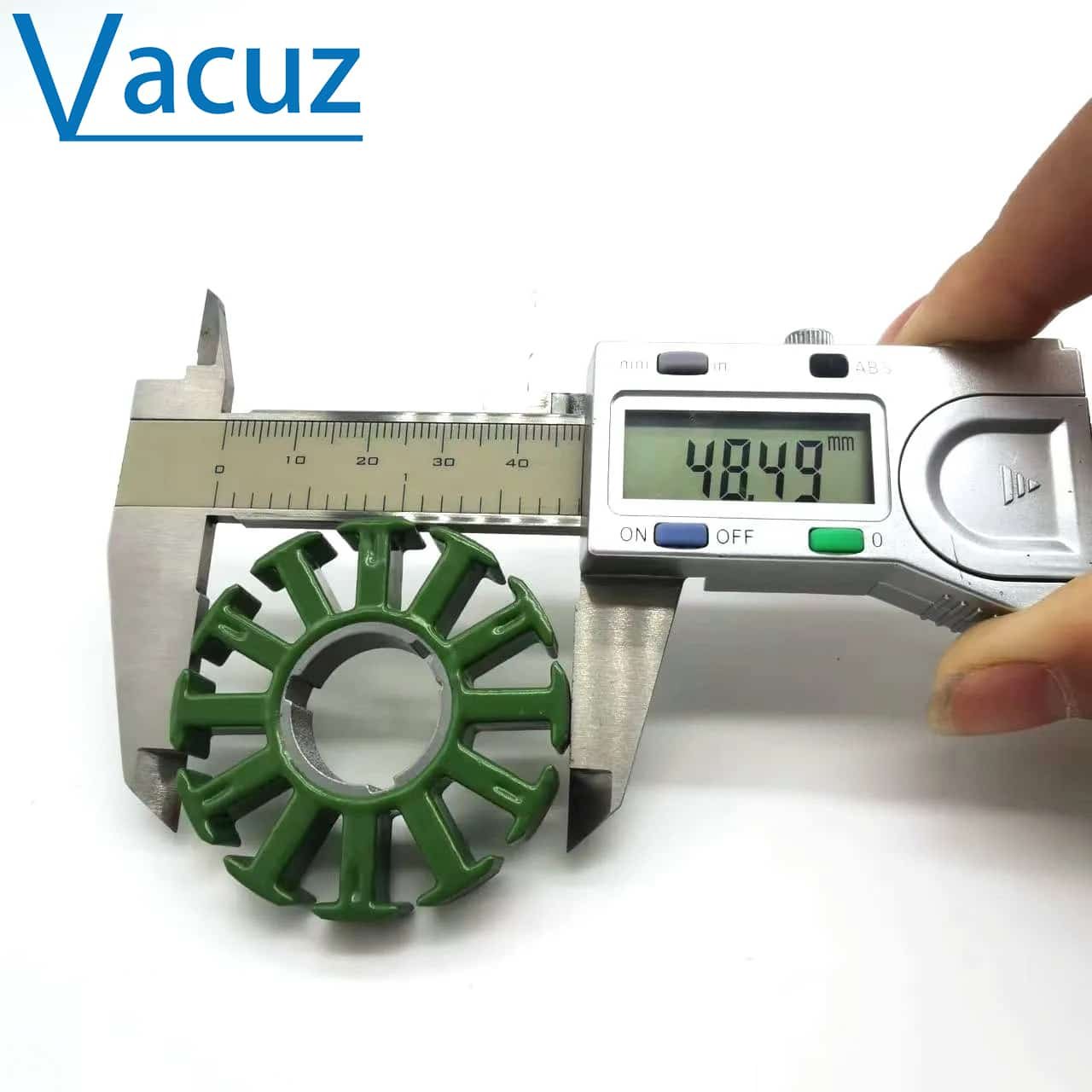

Outer Diameter and Height Adaptation: The outer diameter error ≤ ±0.2mm, and the height error ≤ ±0.5mm, ensuring that the winding machine station and stator dimensions match, reducing mechanical interference.

3. Multi-Station Coordination Accuracy

Positioning Error Between Stations: For multi-station equipment (e.g., four-station, six-station), the positioning error between each station ≤ ±0.05mm, avoiding inconsistent coil shapes due to station deviations.

Speed Synchronization: The winding speed of each station must be synchronized, with an error ≤ ±2%, preventing wire tension fluctuations caused by speed differences.

II. Measures to Improve Winding Quality: End-to-End Optimization from Hardware to Process

1. Hardware Configuration Upgrade

Servo Drive System:

Utilizing a high-precision servo motor paired with a bus-type PLC motion controller, accurate programming control of winding trajectory, angle, and speed is achieved.

Equipped with a closed-loop tension control system, combined with a tension sensor to monitor wire tension in real time, controlling tension fluctuations within ±5%, preventing wire slack or breakage due to unstable tension.

Mold and Fixture Design:

Dedicated winding molds are designed for different stator models, with mold positioning accuracy ≤±0.02mm, ensuring coil shape and size meet requirements.

The fixture adopts a quick-change structure, with changeover time ≤5 minutes, improving production flexibility.

Wire Laying Mechanism Optimization:

A servo-driven wire laying device is used, combined with a ball screw and linear guide, achieving a wire laying device positioning error ≤±0.01mm, supporting high-speed movement requirements.

1. Optimized Wiring Path:A special algorithm generates a smooth path, reducing wire bending stress and preventing wire crossing.

2. Refined Control of Process Parameters:

Winding Speed Adjustment:

Dynamically adjust the winding speed based on wire diameter and stator parameters.

Decelerate in advance in complex wiring areas (such as corners) to ensure a smooth wire transition.

Tension Management:

Set differentiated tensions for different wire materials (e.g., copper, aluminum). Aluminum wire tension should be 10%-20% lower than copper wire tension to prevent paint peeling.

Use dynamic tension compensation technology to adjust tension in real time to counteract wire elastic deformation and ensure tight wiring.

Multi-Wire Parallel Winding Optimization:

For multi-wire parallel winding processes, optimize the wire bundle arrangement sequence to avoid inter-wire interference.

Configure a multi-channel tensioner to independently control the tension of each wire, ensuring uniform parallel winding.

What are the precision requirements for multi-station internal winding machines for motor stators? How to improve winding quality? Vacuz has been explained in simple terms above. I hope this information can be helpful to everyone!