With the rapid development of the motor industry, the demand for motors is also increasing, the traditional production mode requires a lot of manual labor and low efficiency. In order to improve the production efficiency and quality of motors, following the development of technology, motor production gradually towards automation industry, began to have a motor automated assembly production line, so what are the common processes of motor automated assembly production line? Vacuz will give you an introduction to it!

Automatic motor assembly line production process.

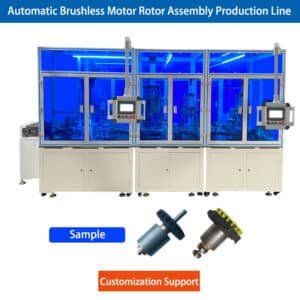

Stator winding, pressed copper sheet, stator performance test, shell coating, stator pressure bearing, installation of permanent magnets; rotor injection, magnetization, installation of the card spring, pressure bearing, terminal bridge bearing holes coated with lubricating grease bracket, O-ring grease, corrugated gasket installation, shaft head magnet press fitting, PCB board installation, hot melt fixed column, air tightness test, etc.

Motor automatic assembly line advantages.

1、The whole line adopts two-speed chain transmission, the transmission speed is accurate and stable, which can ensure accurate synchronization, beautiful structure, high degree of automation, low practical noise and easy installation.

2、The whole line adopts robot handling module responsible for the in and out of materials, strong compatibility, convenient and stable debugging, low failure rate, and high grasping accuracy.

3、The whole line is controlled by industrial control machine, the system automatically codes the equipment tray, the production line data into automatic storage and traceability.

4、The automatic motor assembly line has certain flexibility, which can be modified, expanded and lifted to meet the assembly needs of future product changes.

5、The equipment has internal interlock switch, level adjustment device, manual and automatic operation, and the equipment is equipped with touch screen operation and display.

6、Safety grating is installed on the operating surface of the employees of the automation equipment to ensure the safety of the employees’ operation.

7、Compatible with a variety of products, it can save 80% of production workers, and the quality product rate reaches more than 99%.

The above is the production process and advantages of the automatic motor assembly line. Mastering these basics will help to better understand the benefits of the automatic motor production line.

WhatsApp/ウィチャット+86 13075286997

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].