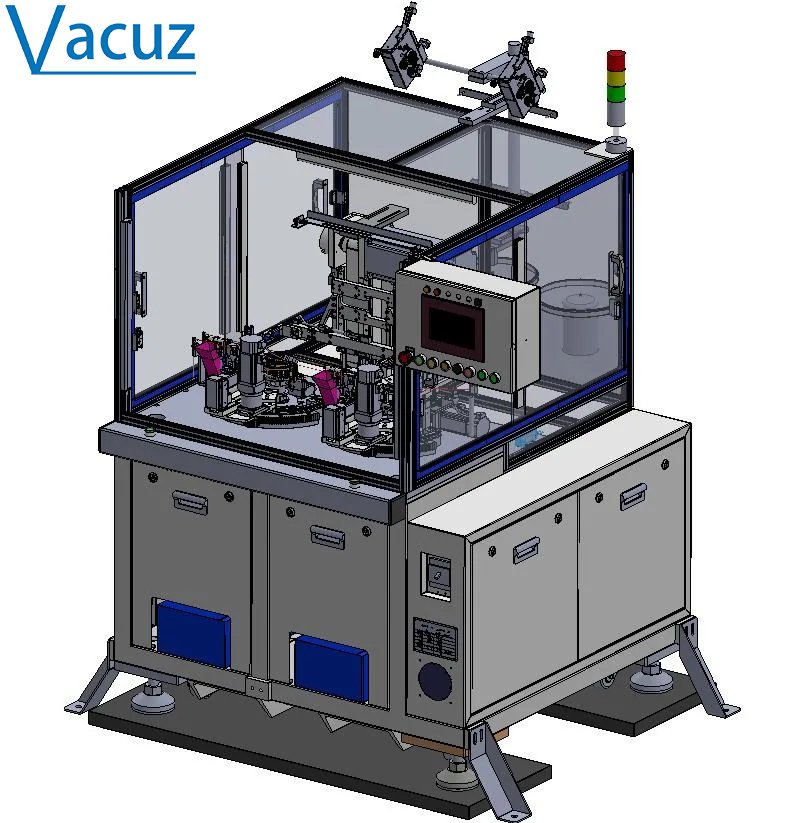

Automatic winding machines for brushless motor stators not only have strict requirements for components like servo motors, but also require careful attention to the selection of wire and nozzles. Improper selection can lead to winding problems. So, what are the wire and nozzle requirements for automatic winding machines for brushless stators? How should you choose? Let’s briefly explain!

I. Wire Requirements and Selection

1. Material and Performance

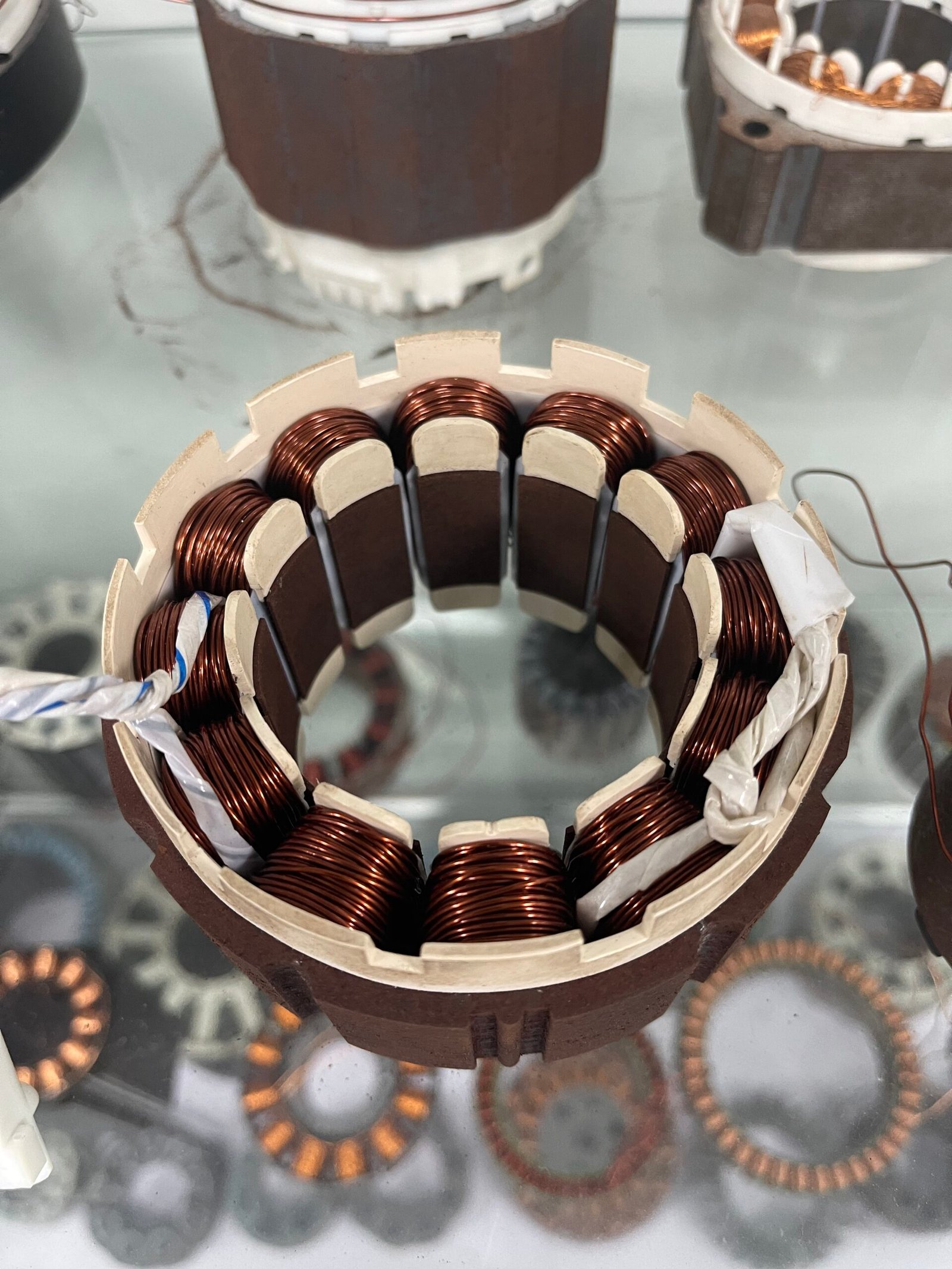

Copper enameled wire: The mainstream choice, offering excellent conductivity and corrosion resistance, suitable for most brushless motor applications. The insulation layer is typically polyurethane or polyamide, offering high-temperature and wear resistance.

Aluminum/iron wire: Aluminum wire is lightweight but offers slightly lower conductivity, while iron wire is highly rigid and suitable for applications requiring high mechanical strength, such as power tools.

Specially coated wire: Wires with coatings such as polyimide or polytetrafluoroethylene are suitable for use in high-temperature, high-humidity, or corrosive environments.

2. Wire Diameter Compatibility

Thin wire (≤0.1mm): Suitable for small motors, requiring high winding speeds and precise tension control to prevent wire breakage.

Thick wire (≥0.6mm): Suitable for high-power motors, requiring a lower winding speed to prevent wire damage. For wire diameters above 1.0mm, a needle-type internal winding machine is recommended.

Multiple-wire Parallel Winding: 0.2-0.3mm wire can be wound in parallel up to 30 strands. Adjust the notch distance to prevent scratching.

3. Key Parameter Matching

Current Carrying Capacity: High-power motors require high-conductivity wire.

Insulation Thickness: Select according to the voltage level and environment. Avoid excessive thickness or thinness.

Notch Distance: When winding thick wire or multiple wires in parallel, increase the notch distance to prevent scratching.

II. Nozzle Requirements and Selection

1. Compatibility

Inner Diameter Matching: The nozzle inner diameter should be slightly larger than the wire diameter to ensure smooth winding (e.g., 0.5mm wire should be matched with a 0.5-0.6mm inner diameter nozzle).

Length and Shape: The nozzle should be compatible with the coil length and winding machine design to avoid interference.

2. Material and Durability

Carbide: High hardness and wear resistance, suitable for long-term operation, but with a high cost.

Ceramic: Smooth surface, minimal damage to wire, but with increased brittleness.

Tungsten Carbide: Wear-resistant and smooth surface, requiring regular rust prevention.

Stainless Steel: Low cost but prone to wear, suitable for budget-conscious users.

3. Precision and Surface Quality

Surface Finish: Requires a smooth, flawless finish to minimize friction.

Radius and Inner Hole Roughness: Radius should be controlled below Ra0.4μm, and inner hole roughness is recommended to be within Ra0.8μm.

III. Comprehensive Selection Recommendations

1. Selection Based on Motor Type

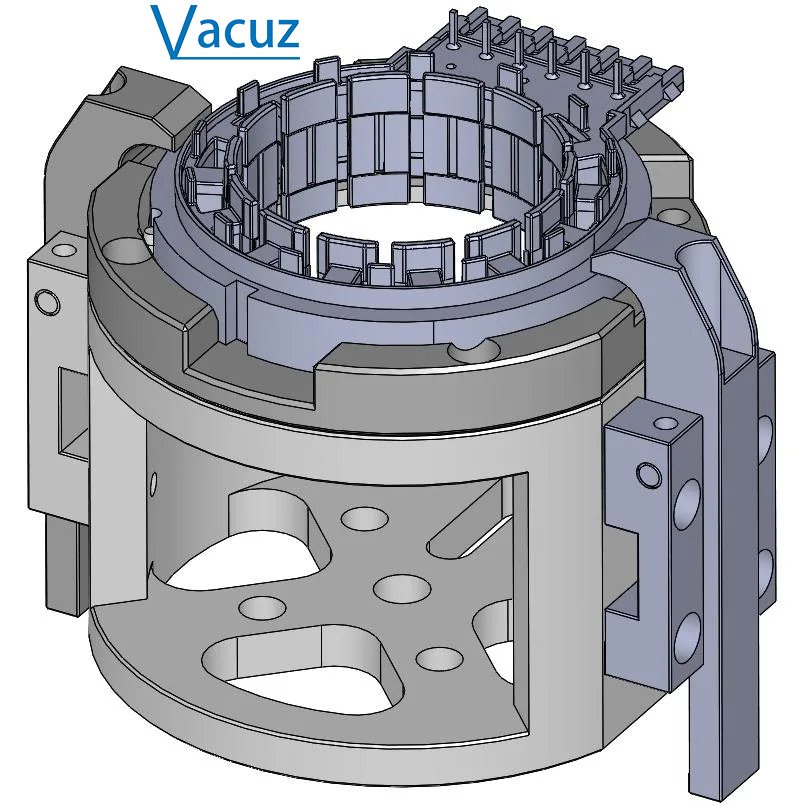

External Rotor Motor: Flying Fork Winding Machine with Carbide/Ceramic Nozzle, suitable for high-speed rotation.

Internal Rotor Motor: Needle Internal Winding Machine with Tungsten Steel/Carbide Nozzle. Use an upper hook for thin wire and a lower hook for thick wire.

2. Selection Based on Production Requirements

High Efficiency Requirements: Highly automated equipment with a high-precision nozzle (such as ceramic) to minimize downtime.

Cost Control: Stainless steel nozzle with conventional copper wire, balancing performance and cost.

3. Selection Based on Environmental Compatibility

High-Temperature Environment: Polyimide-Coated Wire with a Ceramic Nozzle.

Corrosive Environment: PTFE-Coated Wire with a Stainless Steel Nozzle.

Optimization Recommendations

Regular Maintenance: Clean the nozzles, check for wear, and ensure winding quality.

Parameter Testing: Before adding new wire to the winding line, optimize parameters such as tension and speed.

Supplier Collaboration: Maintain communication with wire and nozzle suppliers to obtain the latest technical solutions.

What are the wire and nozzle requirements for brushless stator automatic winding machines? How should you choose? Vacuz has provided a brief explanation above. We hope this information is helpful!

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].