In the design and planning of the rotor automatic production line, the quality and selection of spare parts is critical, they directly affect the overall performance and stability of the production line, the following is a detailed analysis of the requirements of spare parts and to ensure the stable and reliable operation of the machine strategy, Vacuz hope to help you!

First, the requirements of spare parts

1. Quality and precision

a. High accuracy: the manufacture of spare parts need to strictly follow the design requirements to ensure that the assembled rotor to meet the product performance standards, to reduce the lack of precision caused by the performance deviation.

b. High quality: material, strength, wear resistance and other physical properties need to meet or exceed industry standards to enhance the durability and stability of the production line.

2. Compatibility: the size, shape and interface between the spare parts need to have a good match to ensure smooth assembly and reduce the failure rate caused by mismatch.

3. standardization and generalization: promote standardization and generalization of spare parts to reduce procurement costs, improve maintenance efficiency and reduce production interruptions caused by spare parts replacement.

4. Wear-resistant and corrosion-resistant: Select wear-resistant and corrosion-resistant materials for the vulnerable parts to prolong the service life and reduce the failures caused by wear and corrosion.

5. Reliability: spare parts need to go through strict quality control and testing to ensure that they can operate stably and reliably in the process of use.

Second, to ensure the stability and reliability of the machine

1. equipment selection and configuration

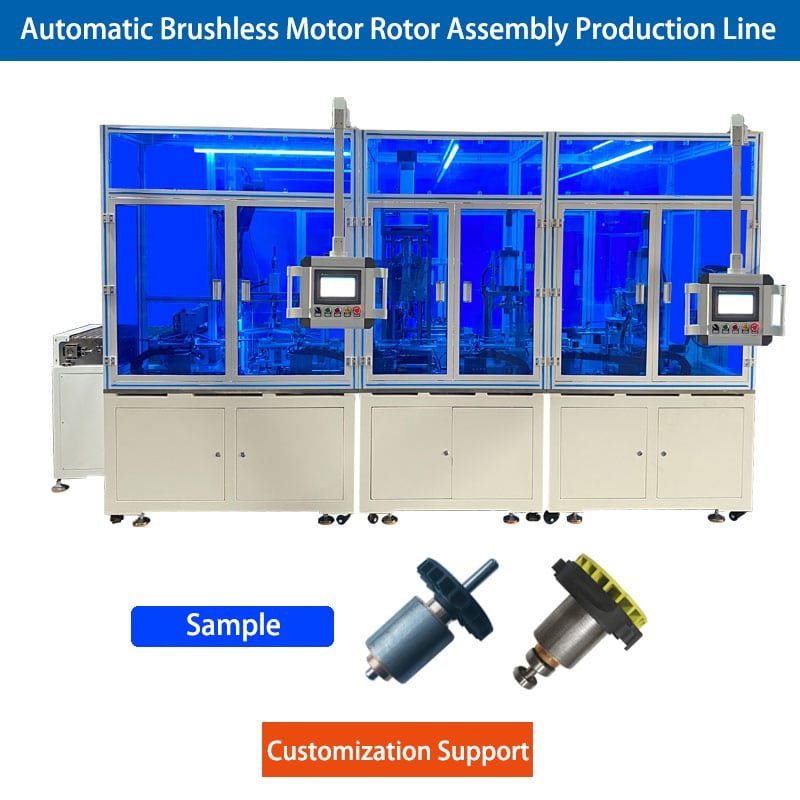

Select high accuracy, high degree of automation of the assembly equipment, such as robot assembly system, to reduce human error, improve assembly precision and efficiency. Reasonable configuration of power supply, gas source and other auxiliary equipment to provide a stable external operating environment for the production line.

2. Environmental control

Strictly control the temperature, humidity, cleanliness and other environmental factors of the production line to reduce the interference of the external environment on the production stability. Ensure that the production site is well ventilated and illuminated to create a comfortable working environment for employees.

3. Process optimization and standardization

Optimize the production process, simplify the operation steps and improve the assembly efficiency. Formulate standardized operation specifications and workflow to reduce human error and ensure the consistency and stability of assembly.

4. Equipment Maintenance

Regular maintenance of equipment, including cleaning, lubrication, replacement of wearing parts, etc., to ensure the normal operation of equipment. Implement regular inspection and replacement strategies for key components to prevent potential failures. Establish equipment maintenance files and repair records to facilitate problem tracking and resolution.

5. Quality control and inspection

Strengthen the quality control of raw materials and production processes to ensure that spare parts and product quality are up to standard. Utilize advanced sensor technology and data analysis tools to monitor the assembly process in real time, and identify and solve problems in a timely manner.

6. Personnel training and management

Regularly provide skill training for employees to improve the level of assembly operation and skill proficiency. Establish incentive mechanism to encourage employees to participate in production line improvement and innovation activities to promote continuous optimization of the production line.

7. Safety and Protection

Establish a perfect safety management system, including equipment operating procedures, emergency response plan for accidents, etc., to enhance employee safety awareness. Take anti-loosening measures for parts that are easy to loosen, such as double nuts, stop washers, etc., to ensure production safety.

To summarize, through strict requirements for spare parts and various management measures, the rotor automatic production line can ensure stable and reliable operation and provide solid guarantee for the production of high-quality products.

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].