There are many types of motor stator winding machines. Different manufacturers produce different winding machines for different products, with varying winding speeds and production processes. So, what is the production process of a high-speed motor stator winding machine manufacturer? How do they meet customer production needs? Vacuz will introduce it to you!

I. Core Production Process: Precision Control from Raw Materials to Finished Products

1. Raw Material Preparation and Mold Adaptation

Wire Selection: Copper or aluminum wire is selected based on the customer’s motor type (e.g., brushless motor, stepper motor), combined with parameters such as wire diameter (0.05mm-1.3mm) and temperature resistance rating. For example, Vacuz collaborates with suppliers to ensure wire tolerance is controlled within ±0.005mm, avoiding the risk of wire breakage.

Mold Design: A modular fixture system is used, supporting rapid mold changeover. For example, for stators with an outer diameter of 10mm-100mm, mold changes can be made within 10 minutes, compatible with different specifications from 6 slots to 24 slots.

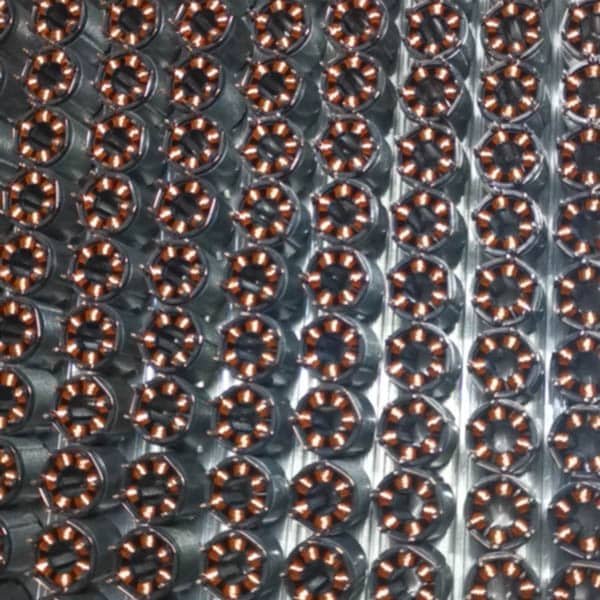

2. High-Speed Winding and Dynamic Control

Servo Drive System: The core component uses Delta or Panasonic servo motors, combined with PLC closed-loop control, maintaining an accuracy of ±0.01mm even at a winding speed of 1200RPM.

Real-Time Tension Adjustment: Integrating tension sensors and AI algorithms, it automatically adjusts the winding tension. The tension is reduced to 0.5N when winding 0.2mm thin wire and increased to 3N when winding 1.0mm thick wire, preventing coil loosening or breakage. Vacuz’s four-station pin-type internal winding machine uses this technology to achieve 14-strand parallel winding of model aircraft motors, increasing slot fill factor by 20%.

3. Wire Laying Optimization and Quality Inspection

Path Algorithm: Automatically generates the wiring path based on stator slot type (e.g., skewed slots, straight slots), reducing the number of slot crossings.

Online Inspection: Equipped with laser sensors and a vision system, it monitors the number of turns, wire laying spacing (error ≤0.02mm), and coil roundness in real time.

4. Post-processing and Delivery

Insulation Treatment: Integrated automatic impregnation or dispensing processes improve coil insulation levels.

Data Traceability: A unique QR code is generated via laser marking to record winding parameters, production time, and operator information, supporting quality traceability.

II. Customer Needs Meeting Strategy: Deep Integration of Customization and Flexibility

1. Support for Multi-variety, Small-batch Production

Modular Design: The equipment supports “one-click model changeover,” automatically adjusting mold position, winding tension, and wire path through preset programs. For example, Vacuz’s four-station fully automatic flying fork stator winding machine can store 50 sets of stator parameters, with a changeover time of ≤3 minutes.

Compatible Molds: Utilizing standard interfaces or adjustable size structures, the same mold is compatible with multiple stator models.

2. Special Process Implementation

Layered/Segmented Winding: For high-power motors, layered winding (decreasing wire diameter per layer) or segmented winding (segmented processing when stack thickness >150mm) is supported. Vacuz equipment achieves cross-series stator compatibility through the addition of shims or auxiliary parts, and its dynamic speed regulation function ensures a 15% speed reduction when the wire diameter increases by 0.2mm.

Multi-wire winding: The winding head is equipped with multiple wire slots or nozzles, supporting winding of two to 14 strands of wire simultaneously.

3. Intelligent and Remote Service

IoT Monitoring: The equipment integrates vibration and temperature sensors, uploading operational data to the cloud in real time. When the winding shaft bearing wears, the system automatically issues a warning and generates a maintenance plan.

Remote Commissioning: Suppliers provide on-site repair guidance via video calls or AR technology, shortening response time. For example, Vacuz offers 24-hour remote technical support, improving troubleshooting efficiency by 60%.

4. Full-Process Technical Support

Customized Solutions: Equipment configuration, parameter settings, and process flow design are provided according to customer motor specifications (such as slot fill factor and number of turns requirements).

Operator Training: The touchscreen graphical interface and fault prompt system lower the operating threshold. The touchscreen operation and fault prompt design of Vacuz equipment allow even novice workers to operate independently within one hour.

High-quality motor stator high-speed winding machine manufacturers achieve high-precision and high-efficiency production through modular design, dynamic control technology, intelligent services, and full-process customization. Their core competency lies in translating the diversity of customer needs into the flexibility of equipment functions, continuously optimizing the production loop through technological iteration and data-driven approaches.