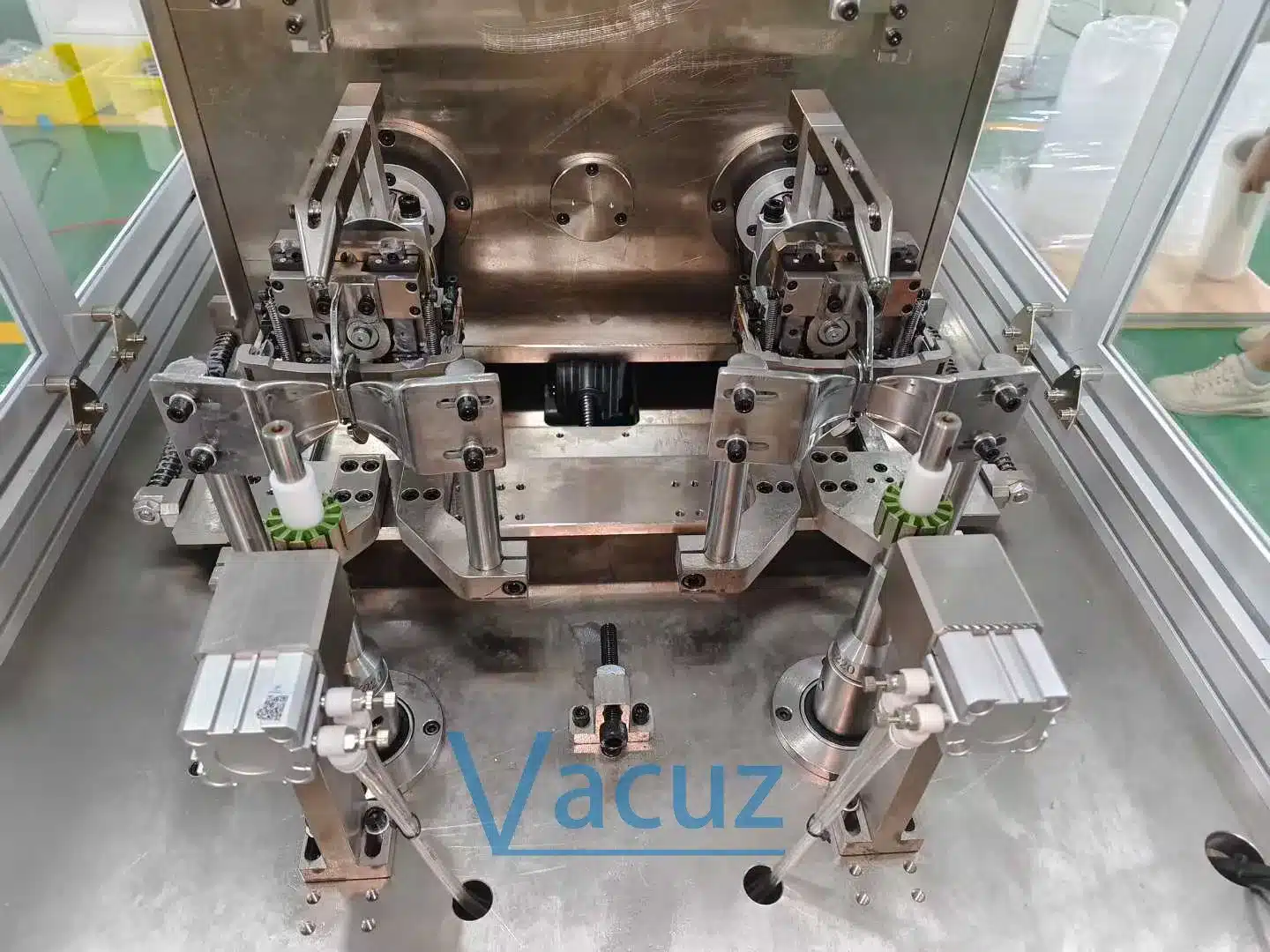

Fully automatic motor winding machines are essential equipment for stator winding. However, sometimes you find that the machine’s operating efficiency is slow and fails to meet your requirements, and you’re unsure of the cause. Below, Vacuz summarizes the core causes, along with improvement solutions and optimization suggestions, for slow operating efficiency. We hope this helps!

I. Core Causes of Slow Operating Efficiency

1. Inadequate Equipment Hardware Configuration

Low motor and drive system performance: Ordinary motors or low-precision drives lack torque and experience response delays at high speeds.

Poor mechanical structure stability: Insufficient frame rigidity, worn guide rails, or aging transmission components lead to vibration or stalling.

Control system computational lag: The PLC or motion control card operates at a slow speed, unable to meet production requirements in real time.

2. Wire material mismatch with process parameters

Wire diameter and material differences: Thicker wire requires slower speed to prevent breakage, while thinner wire can be faster. Aluminum and iron wire are softer than copper, requiring adjustment of tension parameters.

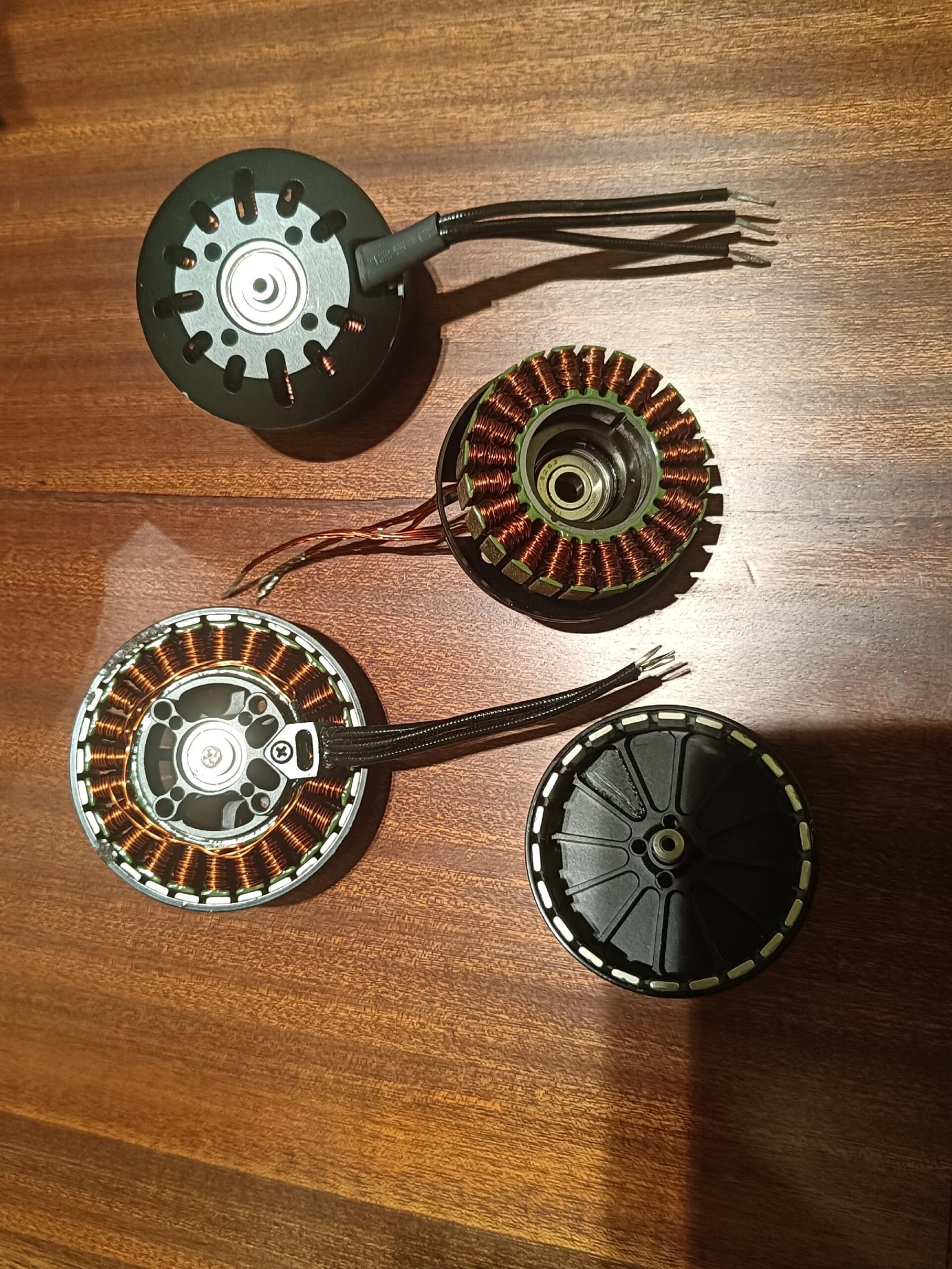

Complex Winding Methods: Parallel winding of multiple wires or special structures (such as skewed stators) requires customized processes, reducing efficiency.

3. Operation and Debugging Issues

Incorrect Parameter Settings: Winding speed, acceleration/deceleration times, and winding tension are not optimized, leading to wire breakage or uneven arrangement.

Low Mold and Tooling Precision: Machining errors or improper installation can cause scratches or interference, forcing speed reduction.

4. Inadequate Maintenance and Care

Wear of Key Components: Failure to promptly replace vulnerable parts such as winding needles and guide pulleys increases winding resistance.

Inadequate Cleaning and Lubrication: Dust accumulation or insufficient lubricant can exacerbate mechanical wear.

5. Environmental and External Factors

Uneven Installation Floor: Vibration can reduce equipment accuracy, requiring speed reduction to compensate.

Abnormal Temperature and Humidity: High temperatures can cause electrical components to overheat, while low temperatures can cause lubricant to solidify.

II. Solutions to Improve Efficiency

1. Upgrade Equipment Hardware

Select high-performance servo motors and precision drive systems to increase torque and response speed.

Strengthen machine frame rigidity, employ precision guides and wear-resistant transmission components to reduce vibration.

Upgrade the PLC or motion control card and optimize the control program to reduce latency.

2. Adapt to Wire Material and Process Parameters

Dynamically Adjust Tension and Speed: Use a servo-activated wire tensioner to optimize parameters in real time.

Develop efficient winding processes: Reduce time waste by addressing single-layer, multi-layer, or parallel winding requirements.

3. Standardize Operation and Debugging Procedures

Optimize parameter combinations such as winding speed, acceleration and deceleration times through testing.

Regularly calibrate the die and wire guide to ensure positioning accuracy.

4. Strengthen Equipment Maintenance and Care

Establish a schedule for daily cleaning, weekly lubrication checks, and monthly replacement of wearing parts.

Invite technicians for regular comprehensive inspections and in-depth maintenance.

5. Introducing Intelligent Control and Monitoring Technology

Use sensors to monitor tension, torque, and other data in real time to automatically optimize winding speed.

Leverage IoT technology to remotely monitor equipment status and proactively detect potential faults.

6. Optimizing Production Processes and Environmental Management

Increase the number of workstations within the equipment’s capabilities to shorten the winding cycle per piece.

Ensure appropriate workshop temperature and humidity (20-25°C, 40%-60% humidity) and reduce external interference.

III. Additional Recommendations

Employee Training: Regularly provide skills training to operators to ensure standardized parameter settings and maintenance procedures.

Data-Driven Optimization: Collect production data, analyze efficiency bottlenecks, and implement targeted improvements.

Supplier Collaboration: Maintain communication with equipment manufacturers to obtain the latest technical support or upgrade options.

The above measures can significantly improve the operating efficiency of fully automatic motor winding machines while maintaining quality and stability. For further discussion of specific implementation plans, please provide more details so that Vacuz can provide customized recommendations.

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].