With the gradual increase in demand for electric motors, automatic brushless winding machine industry has followed the fire, compared to the traditional manual semi-automatic winding machine, automatic winding machine not only higher production efficiency, and winding line are more neat, suitable for mass production in the motor manufacturing industry, then the automatic brushless winding machine structure how? What are some of the roles?

1. Overall frame of automatic brushless winding machine: The frame is made of sheet metal, aluminum alloy plus stainless steel table, and is equipped with casters for easy movement. After the equipment is installed in place, the legs can be lowered to obtain stable support.

2. Tensioning mechanism: Installed in the wire inlet, it is used to adjust the tension during winding to ensure constant tension during the winding of the stator coil. The tension regulator has an adjustment knob to automatically adjust the tension according to different needs.

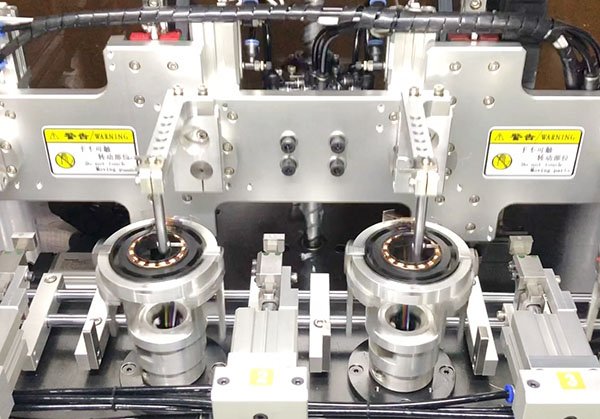

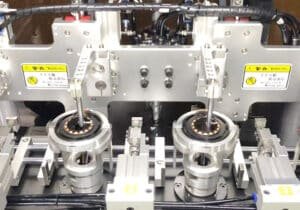

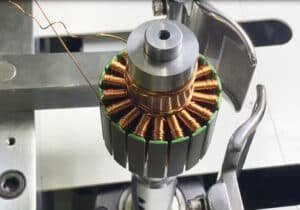

3. Automatic brushless winding machine winding mechanism: mainly consists of servo motor, synchronous toothed belt and winding fork, after the fork rotates, the copper wire will be wound on the winding mold, which is one of the core moving parts of the winding machine.

4. Wire arranging mechanism: including servo motor, precision linear screw, precision guide, cylinder, etc. It realizes the winding action through forward and reverse reciprocating motion, and is also one of the core moving parts of the winding machine.

5. Working turntable: It consists of indexing stepping motor, turntable, wire fork and winding die, which can realize process actions such as wire cutting, heating, demoulding, etc. It needs to complete the working turntable according to different work station actions.

6. Electrical control: including electrical control box and touch screen operation box. With motion controller as the control core, touch screen as the human-machine interaction, servo motor as the actuator, to achieve accurate control of the rotary axis and winding line, and thus ensure the accuracy of winding.

The above is the basic structure of the automatic brushless winding machine, the precision of the winding machine and the above components are closely linked, one is indispensable, only a full understanding of the composition of the structure, in order to better use the winding machine!

WhatsApp/ウィチャット+86 13075286997

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].