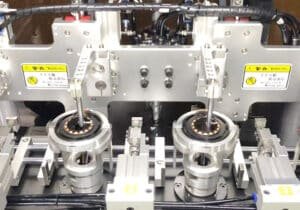

Manual semi-automatic winding machine is gradually eliminated, automatic winding machine types began to increase, the application is becoming more and more widespread, the motor is one of the core components of the winding machine, the stability and durability of the motor largely affects the performance of the winding machine machine. Of course, the winding machine technology continues to improve, motor technology is also constantly improving, including stepper motors, servo motors, inverter motors, etc. With these motors, the performance of the winding machine to steadily rise.

1. AC asynchronous motor, the main advantage is the low price, mature technology, also commonly used in the winding machine spindle motor, in the traditional CNC winding machine, automatic winding machine, transformer winding machine are used, now many winding machines use inverter, so the control circuit is relatively simple, with the inverter motor can achieve speed adjustment, braking, forward and reverse winding functions, can be said to be more convenient.

2. stepper motor, the main advantage is positionable, controllable, small size, in the automatic winding machine is also very important, mainly used in the line mechanism, position moving device, we all know that the winding line accuracy is very important, if the effect is not good, it may not meet the needs of customers. Therefore, the choice of stepper motor is very important.

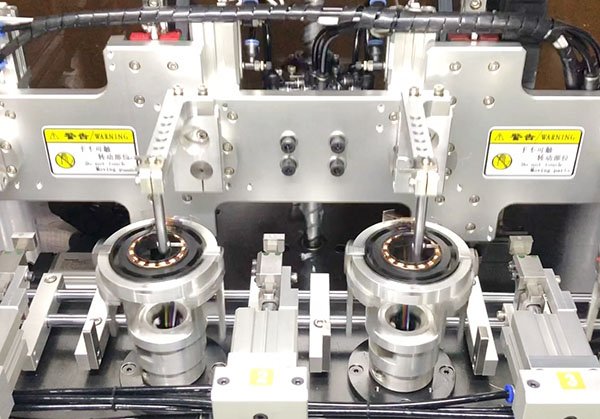

3. Servo motor, the main advantage is high precision, closed-loop control, used in the winding machine, can achieve positioning, fast start and stop, can control the rotation distance, rotation angle and other parameters. At present, it is the best of the motors. In the winding machine, it can be used as the spindle motor, the stopping position is more accurate, it can meet the cross-slot winding process, the output torque can be controlled, it can meet the fine line row, which can make the row more neat.

In fact, it is not which motor is good, choose which motor, in fact, in the winding machine, a more economical way is to reasonably match the motor, stepper motor can meet the requirements, there is no need to use servo motor; stepper motor can not meet the, we try to use servo motor, because in terms of price, the difference is still quite large.

WhatsApp/ウィチャット+86 13075286997

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].