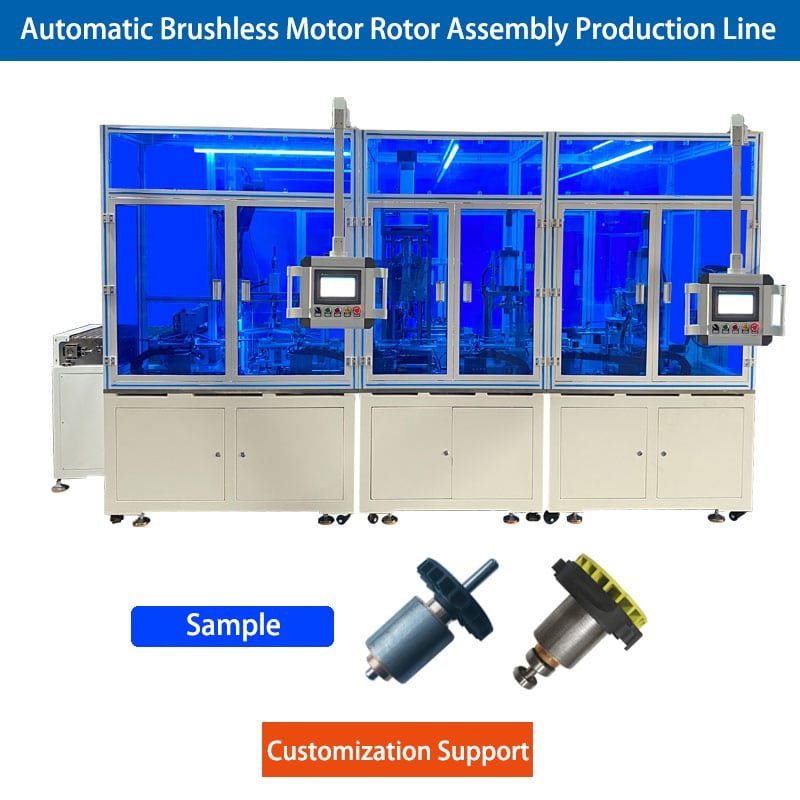

With the continuous development of science and technology, the demand for motors is growing, the production technology is also more and more high-tech, for example, the stator and rotor assembly, now most of the professional automated production line, automated production line application, reflecting the modern motor manufacturing industry to automation, high efficiency, intelligent development trend, then why stator rotor assembly using production line? What are the specific advantages and requirements? Here Vacuz to analyze it!

Reasons for adopting production line assembly:

1. Enhance production efficiency: automated or semi-automated production line can significantly accelerate the production process of stator rotor, shorten the production cycle, thereby enhancing the overall production efficiency.

2. Ensure product quality: Accurate and accurate equipment control and testing mechanism effectively reduces the interference of human factors on product quality, ensuring the accuracy and stability of the stator rotor.

3. Reduce production costs: through large-scale production and process optimization, the consumption of raw materials and labor costs are effectively controlled, which in turn improves the overall economic efficiency.

4. Adapt to market demand: production line assembly has a high degree of flexibility and scalability, can quickly respond to market changes, adjust the production scale and product type.

Advantages of production line assembly:

1. High efficiency: automation and standardization of production methods to ensure high productivity and output, to meet the needs of mass production.

2. Accuracy: Highly accurate equipment control and testing ensures that all parameters of the stator and rotor meet the design requirements, which improves the quality of the products.

3. Reliability: Reducing human errors and omissions makes the products more reliable and prolongs the service life.

4. Cost reduction: through large-scale production and process optimization, it reduces the production cost and improves the market competitiveness of the enterprise.

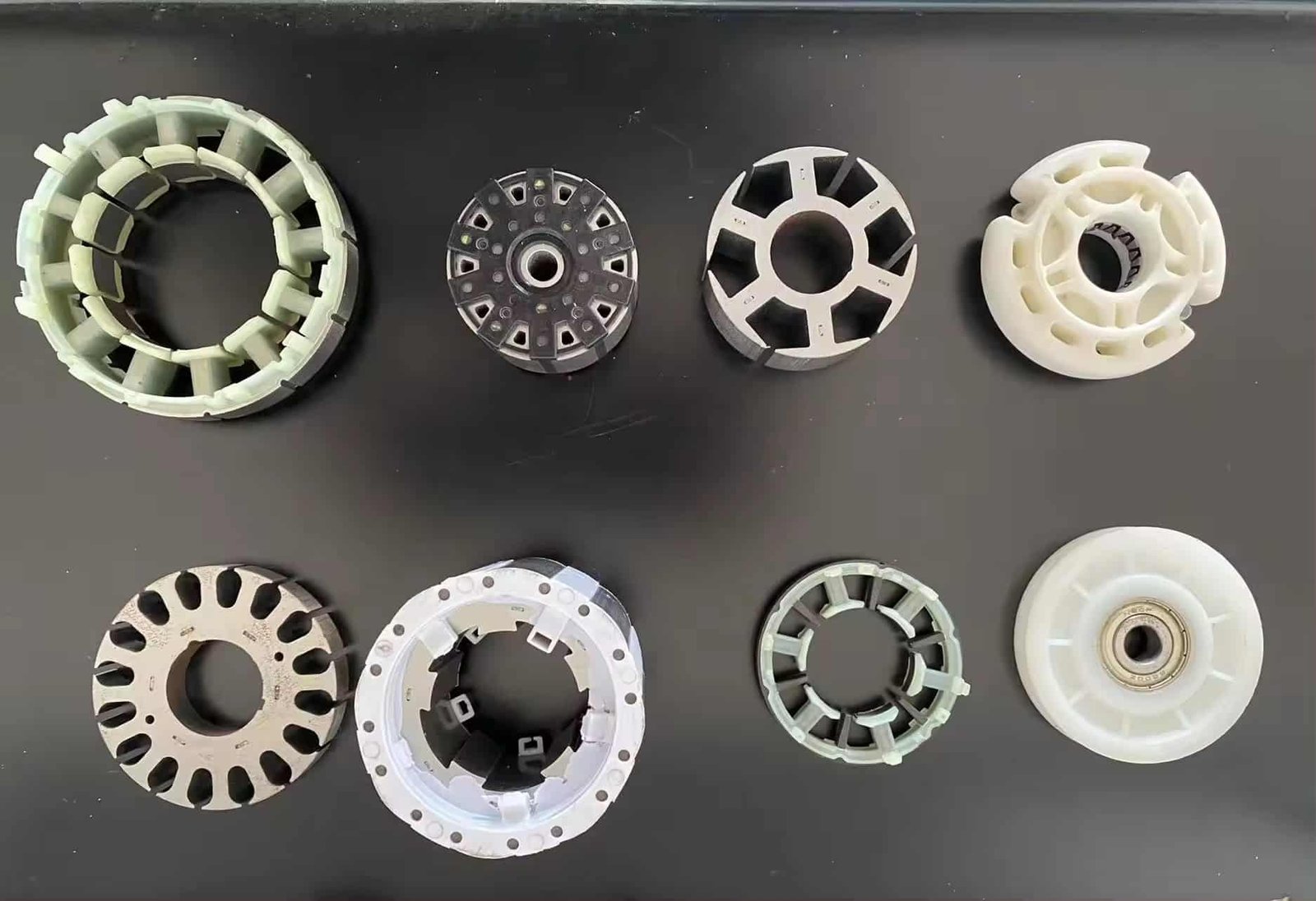

5. Flexibility: the production line can be flexibly adjusted to adapt to the production needs of different models and specifications of the stator rotor, to meet the diversified needs of the market.

Requirements for production line assembly:

1. Excellent equipment: the production line should be equipped with high-quality machines, equipment, guide rails, cylinders, motors, servo drives, etc. to ensure the stability and precision of operation.

2. Smooth process: each production link should be closely connected to ensure the continuity and smoothness of the production process. At the same time, the production line design should be simple and clear, easy to operate and maintain.

3. Real-time monitoring: It should have real-time monitoring function to monitor all aspects of the production process and provide real-time feedback on production data and abnormalities for timely adjustment and processing.

4. Safety and stability: the production line should comply with safety standards and have perfect safety protection measures to ensure the safety of personnel and equipment in the production process.

5. Adaptability and expandability: the production line should have a certain degree of adaptability and expandability, in order to quickly adjust and optimize according to market demand and product changes.

In summary, the stator rotor assembly line is a wise choice for the motor manufacturing industry, which can not only improve production efficiency, ensure product quality, reduce production costs, but also better adapt to changes in market demand. Enterprises should actively adopt advanced production line assembly technology to enhance their core competitiveness and market position.

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].