In this project, the logic control chip receives the input signal feedback from the sensor and outputs the corresponding control signal to the relay control module based on the feedback signal to reduce the winding speed. The logic control chip 74LS21P meets the control requirements of the project. The logic control chip 74LS21 consists of two sets of 4 inputs and gates (positive logic). Typical values of its main electrical characteristics are: tPLH8ns, TPHL10ns, PD9MW2. Relay Module Automatic Winding Machine The electromagnetic relay used in this project consists of an iron core, coil, armature, contact reeds, etc. As long as the voltage is at the two ends of the coil, the coil current will flow through a certain, resulting in an electromagnetic effect, the armature, under the action of the electromagnetic force, to overcome the reset spring’s tension will be the armature attracted to the iron core on the armature, the armature’s moving contacts and static contacts (normally open contacts) are pulled together. When the coil is de-energized, the electromagnetic attraction decreases and disappears, and the armature returns to its original position under the action of the spring reaction force, so that the movable contacts and the original static contacts (normally closed contacts) are released.

This can achieve the purpose of circuit on and off. The normally open and normally closed contacts of a relay can be distinguished as follows: the static contacts that are disconnected when the relay coil is not energized are called normally open contacts; the static contacts that are in a conductive state are called normally closed contacts. Relays generally have two circuits, i.e., a low-voltage control circuit and a high-voltage operating circuit as one circuit. When there is no voltage or insufficient voltage across the relay coil, the common terminal (COM) of the relay is connected to the normally closed terminal (NC). When the voltage between the relay coils reaches saturation, the common terminal (COM) of the relay is connected to the common terminal (NO).

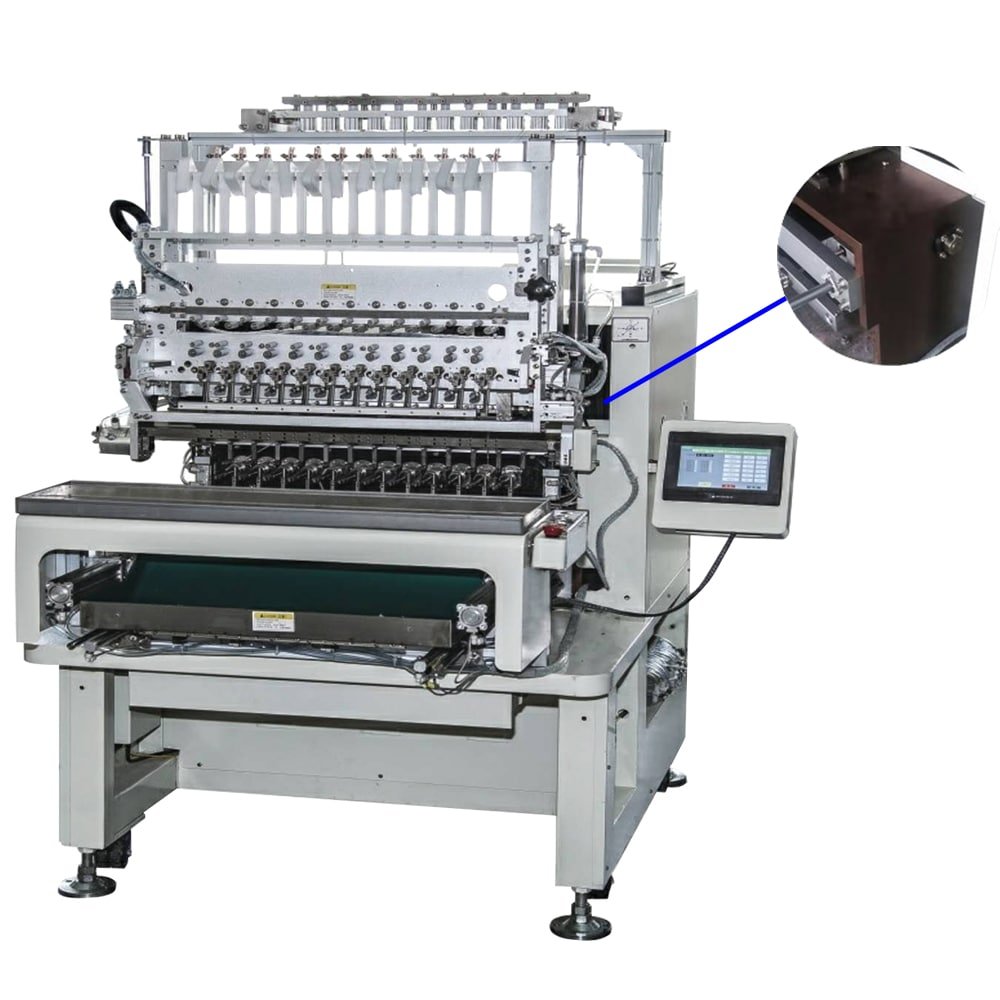

What should I pay attention to the maintenance of the automatic winding machine? Targeted maintenance of the winding machine is very important. Its importance and necessity is reflected in the fact that the winding machine is a precision equipment. Regular maintenance is important. Correct use and reasonable maintenance can ensure the service life of automatic winding machine equipment, reduce the failure rate.

1. Automatic winding machine equipment is fast, stable winding quality, automatic winding machine equipment has been widely used in the production and application of conventional electronic coils. Any kind of equipment can not be separated from the maintenance. This is especially important for automatic coil winding machine. Many components in the equipment are fragile and require regular maintenance and repair to maximize efficiency.

2. Automatic winding machine equipment in the maintenance process should follow the maintenance process of wearing parts – electrical parts – mechanical parts. Perishable parts are mainly friction, rolling and stress during the operation of the equipment. Parts, usually the manufacturer will indicate the wearing parts; the maintenance of electrical parts is mainly dust removal, checking the heat sink, checking whether the electrical interface is effectively connected. Mechanical parts should be tightened during routine maintenance. The connection of each part lubricates the rotating and moving parts of the bearings.

3. Whether the automatic coil winding machine equipment can play a role in the performance, the first step is to use it correctly, and then can follow the maintenance work. Therefore, manufacturers must strictly follow the routine maintenance of automatic winding machines.

WhatsApp/ウィチャット+86 13075286997

電子メール:sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form].