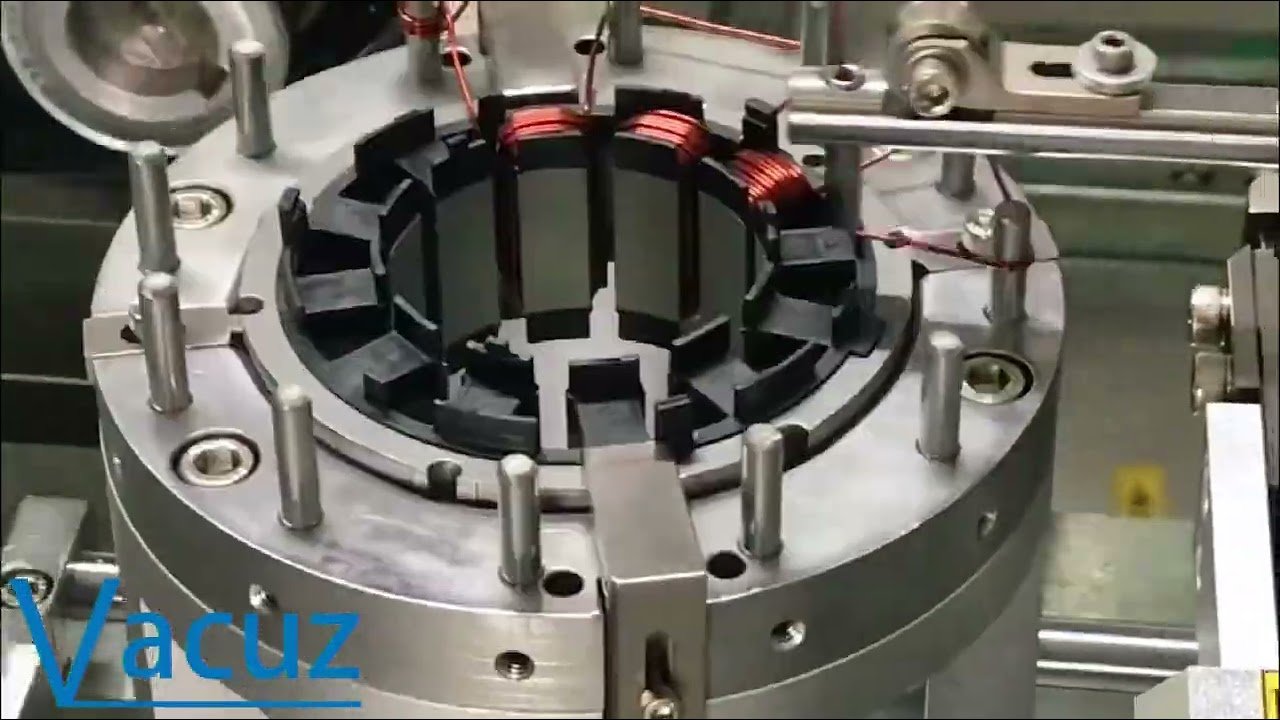

Winding the stator of a brushless motor requires a winding machine. Common winding machines, besides external winding machines, include internal winding machines. Internal winding machines are mainly for stator products with the slots facing inwards. So, what are the configuration and requirements for a pin-type internal winding machine for motor stators? How to find a high-quality internal winding machine? Below, Vacuz brushless motor winding machines will give you a brief introduction!

I. Core Configuration Requirements

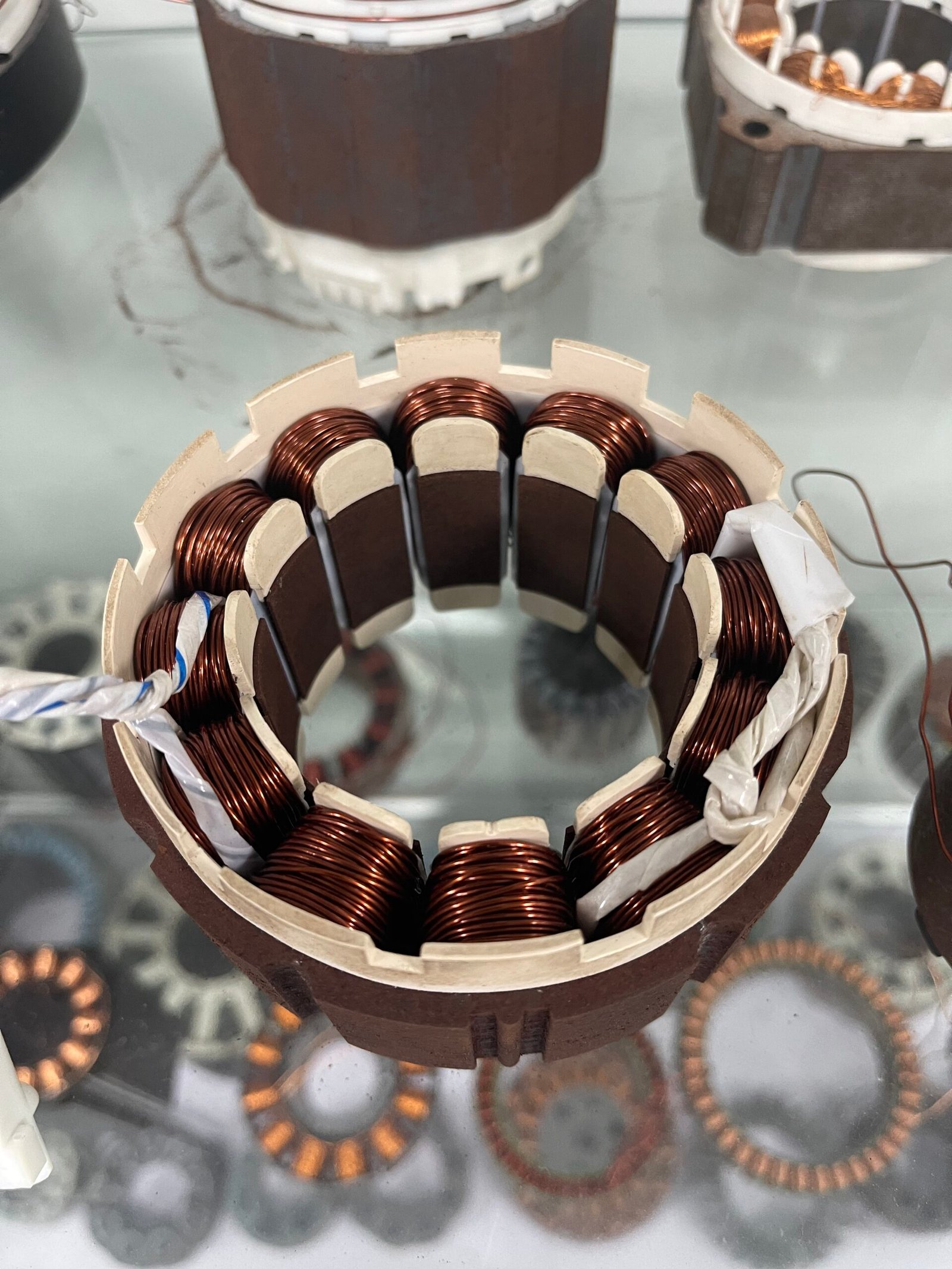

1. Stator Parameter Compatibility

Outer and Inner Diameter Range: Standard models must cover Φ20-Φ130mm outer diameter and Φ12-Φ100mm inner diameter; exceeding this range requires customization.

Stack Thickness Control: Stack thickness (stator height) must be within 5-80mm; high stack thickness requires customization.

Slot Spacing: When the wire diameter is ≤0.1mm, the slot spacing is 2.5-3mm; for thicker wire diameters, the slot spacing needs to be increased to avoid scratches.

2. Winding Process Precision

Wire Diameter Range: Single wire must support Φ0.08-Φ1.3mm; multi-wire winding requires precise tension control. The Vacuz brushless motor internal winding machine supports wire diameters of 0.1-1.2mm, adaptable to multi-pole motors.

Winding Method: Pin-type up-and-down movement winding requires a servo drive structure to ensure pin trajectory accuracy ±0.02mm, preventing coil deformation.

Wire Arrangement System: Multi-station design (e.g., four-station) allows simultaneous winding of multiple stators, improving efficiency. The Vacuz brushless motor internal winding machine improves efficiency by 30%, with neat coil arrangement.

3. Automation and Intelligence

Control System: PLC or touchscreen operation, supporting programming of turn count, direction, and wire cutting angle.

Tension Control: Precision tension system (e.g., magnetic powder tensioner) ensures tight winding of thick wires and prevents breakage of thin wires.

Fully Automated Process: No manual intervention required from loading to unloading.

4. Structure and Stability

Spindle Direction: The longitudinal spindle is adapted for multi-pole motor winding, reducing vibration.

Air and Power Supply: Requires 0.5-0.7MPa air pressure and 380V three-phase power, with a power range of 2-26KW to ensure high-speed operational stability.

Materials and Processes: Key components (such as needles and guide wheels) require heat treatment or precision grinding, with an MTBF (Mean Time Between Failures) exceeding 8000 hours.

II. Selection Criteria for High-Quality Equipment

1. Technical Strength and Patents

Prioritize manufacturers with more than 10 winding technology patents to ensure equipment innovation.

2. Industry Experience and Case Studies

Over 10 years of industry experience, accumulating multi-scenario solutions.

3. Service System and Response

Full Lifecycle Service: Includes installation and commissioning, operation training, “three guarantees” warranty (2 years for the whole machine), and regular maintenance.

Customization Capability: Ability to adjust the equipment structure according to irregularly shaped workpieces or special processes.

4. Cost-Effectiveness and Certifications

Price Comparison: With the same configuration, Vacuz equipment is 5%-10% cheaper than the market average, making it suitable for cost-sensitive customers.

Certification Standards: Certified by ISO9001, CE, TUV, etc., ensuring quality meets international requirements.

What are the configuration and requirements for a motor stator pin-type internal winding machine? How to find a high-quality internal winding machine? Vacuz has provided a brief explanation above; we hope this information is helpful!