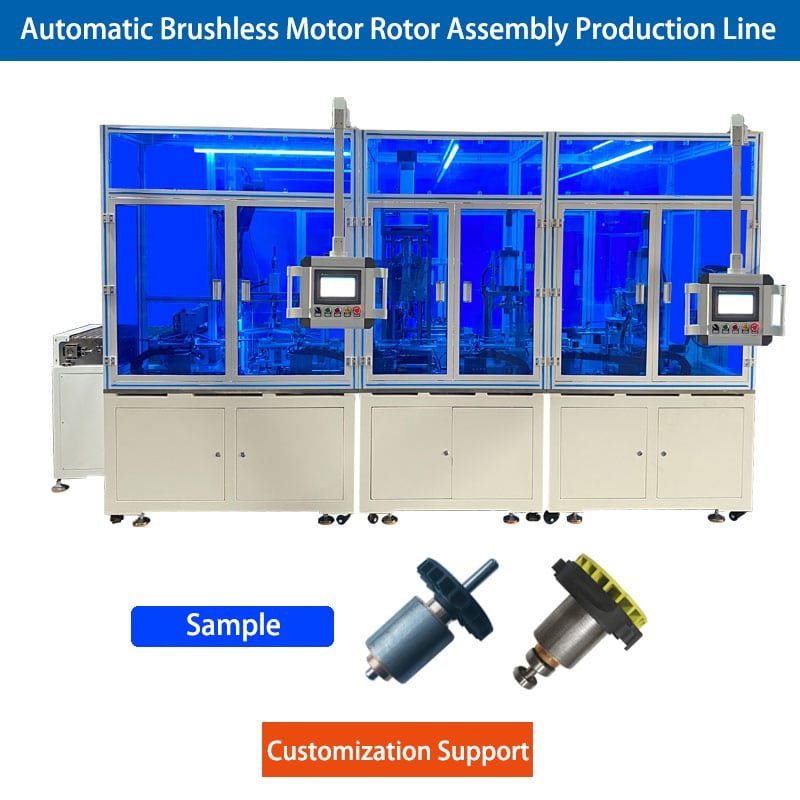

Non-standard automation equipment, with a wide range of applications, flexible customization, convenient operation and diverse functions, has brought new business opportunities for the development of industrial manufacturing. This is also true for the production of brushless motors, which are commonly used in a variety of non-standard automation equipment. Of course, in the process of using non-standard automation equipment, the equipment basically needs to be debugged, so what are the common debugging skills and methods?

1. understand the brushless motor product characteristics, including: appearance, size, tolerance, structure, process, programming, etc.

2. Clean standard parts and non-standard machined parts, select core components, and assemble and commission from core components. During the assembly process, the accuracy of the assembled parts should be checked and measured to ensure level, verticality, concentricity and fit.

3. Single cylinder pushing and pulling or lifting part should ensure pulling in place, pushing in place and no abnormal resistance.

4. The rotating part should ensure the balance, verticality and concentricity of the rotating part to reach the swing arm and the accuracy of indexing.

5. Pins and slots. The place with pin hole and slot should be cleaned up and suitable pin positioning should be selected. The pin is best to fit tightly on one side for easy disassembly and assembly; the accuracy of the slot meets the requirements and should not be too big and too tight to ensure the accuracy in the second assembly.

6. The feeding part depends on the product, the tolerance band is about 0.1, which can ensure the product pass through the material channel unimpeded.

7. Screw, slide, non-standard automation equipment assembly should pay special attention to the nut and slide, not to slide out of the screw and slide, to avoid the ball off, resulting in product scrap or affect the accuracy. Ensure the parallelism, perpendicularity and concentricity of the parts before assembling. Prevent unqualified parts from fixing the screw and slide rail during assembly, leading to scrap.

Brushless motor production needs automation equipment, automation equipment needs to master the above skills, only familiar with non-standard automation equipment debugging skills, reasonable and flexible in the actual application process to make the equipment run stable, reduce equipment production costs and improve the economic efficiency of enterprises.

왓츠앱/위챗: +86 13075286997

이메일: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="작은 가시성,중간 가시성,큰 가시성" class="" id=""][/fusion_form]